Open Day Registration – March 2024

We’re looking forward to welcoming you to Podmores for our March Open Days. Please select a date and then a time below. What’s New High speed feeding – sachets & flow wrapped products with the

Podmores will be closed from Friday 22nd December 2023 until Tuesday 2nd January 2024. Wishing you a very Merry Christmas from all at Podmores.

Latest news

See what’s been going on recently at Podmores

We’re looking forward to welcoming you to Podmores for our March Open Days. Please select a date and then a time below. What’s New High speed feeding – sachets & flow wrapped products with the

A quick tour around our July 2023 Open Week demonstrating a range of new product solutions.

We’re looking forward to welcoming you to Podmores for our July Open Day. Please select a date and then a time below. What’s New Here are some of the new products and solutions Podmores will

Podmores are delighted to announce that we are now a UK partner for Asyril. Asyril’s Asycube range of Flexible Feeders compliment perfectly Podmores’ range of parts handling and feeding products and allow us to provide

Knowing how your Vibratory Linear Feeder or Vibratory Bowl Feeder is performing is a critical part of any maintenance and performance monitoring process. Podmores have made available various tools to help you measure the amount

Podmores are delighted to announce that our October 2022 Open Day registration is live. Book your place now!

Podmores are delighted to announce that our September 2022 Open Day registration is live. Book your place now!

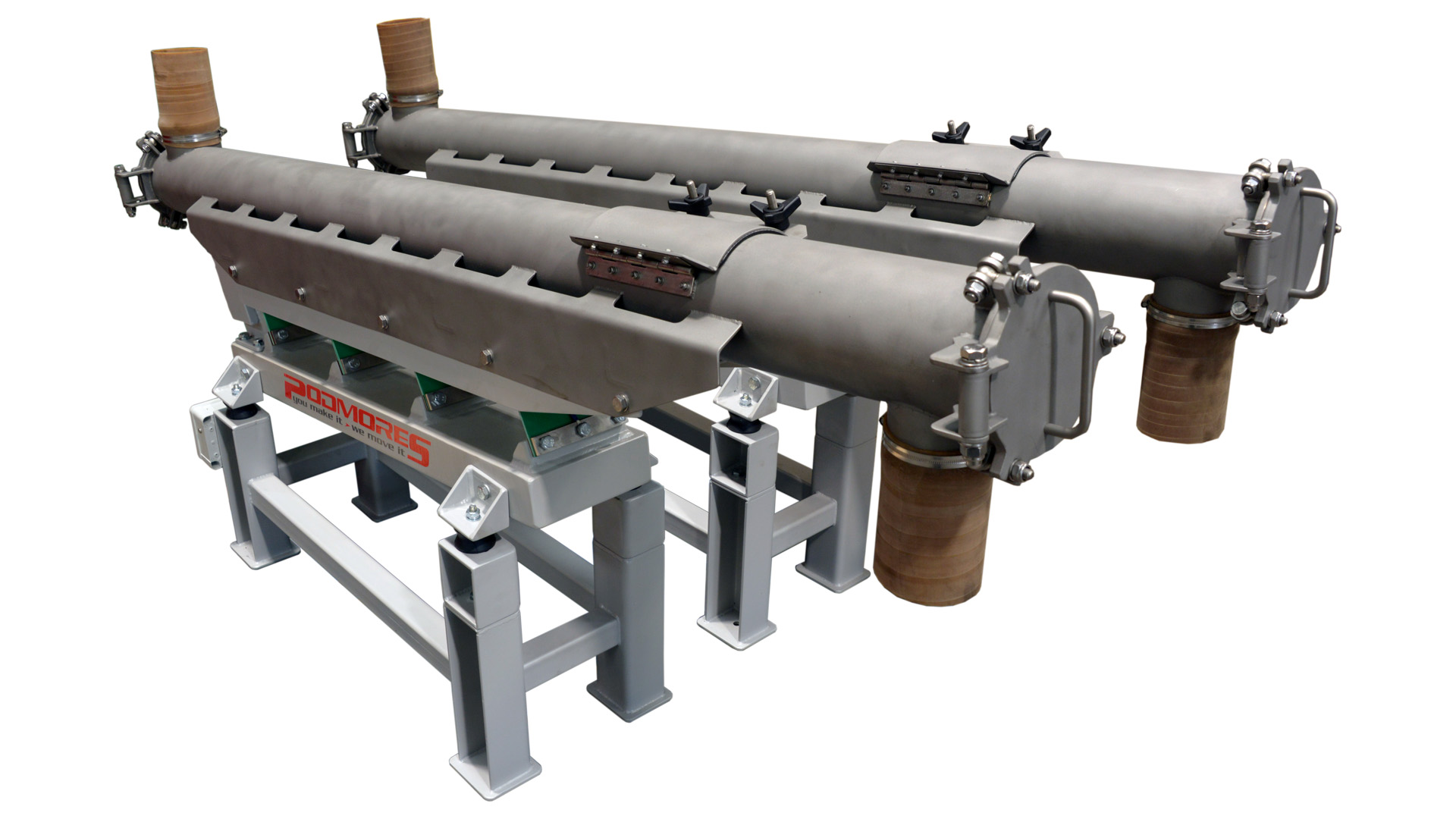

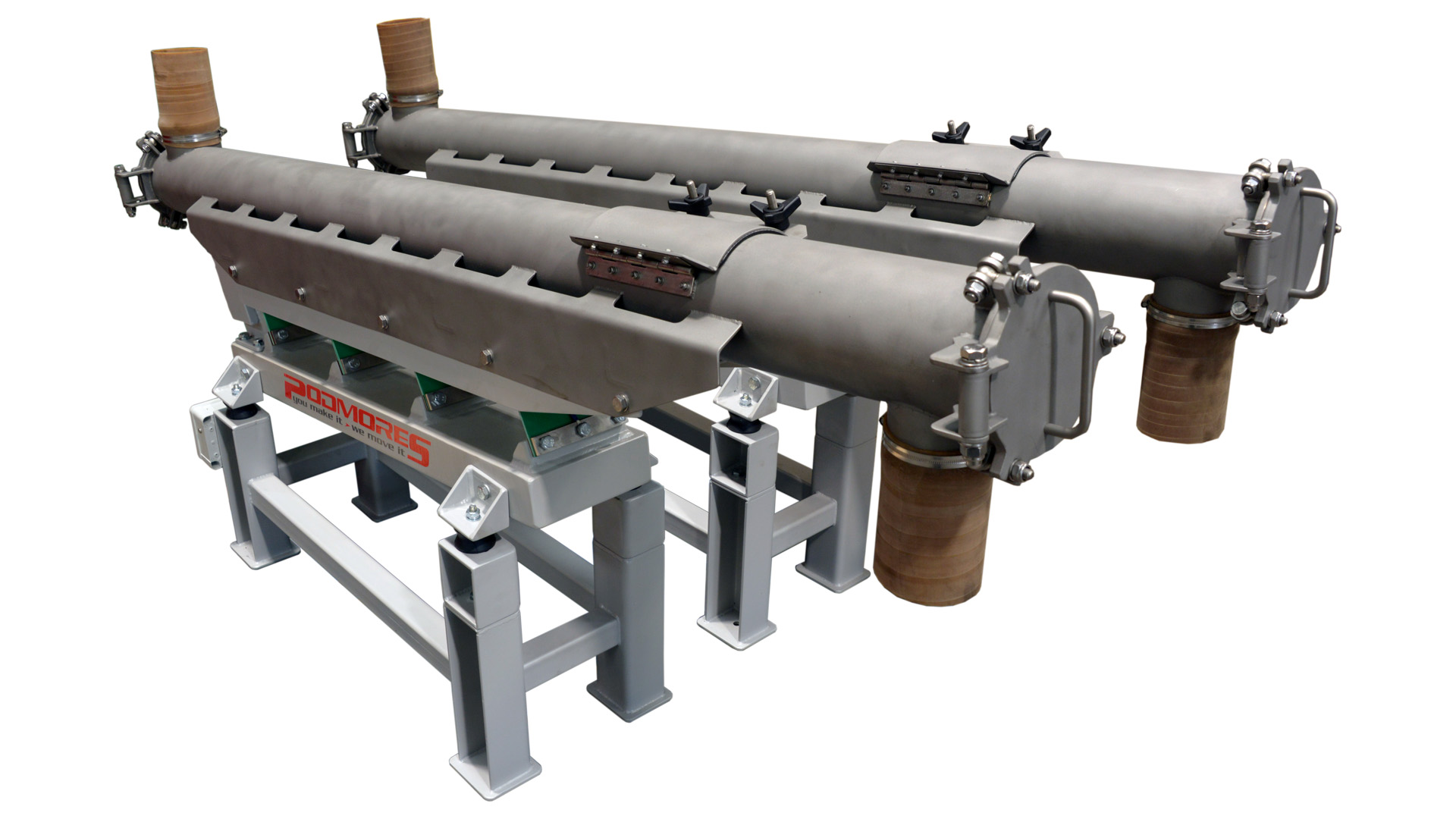

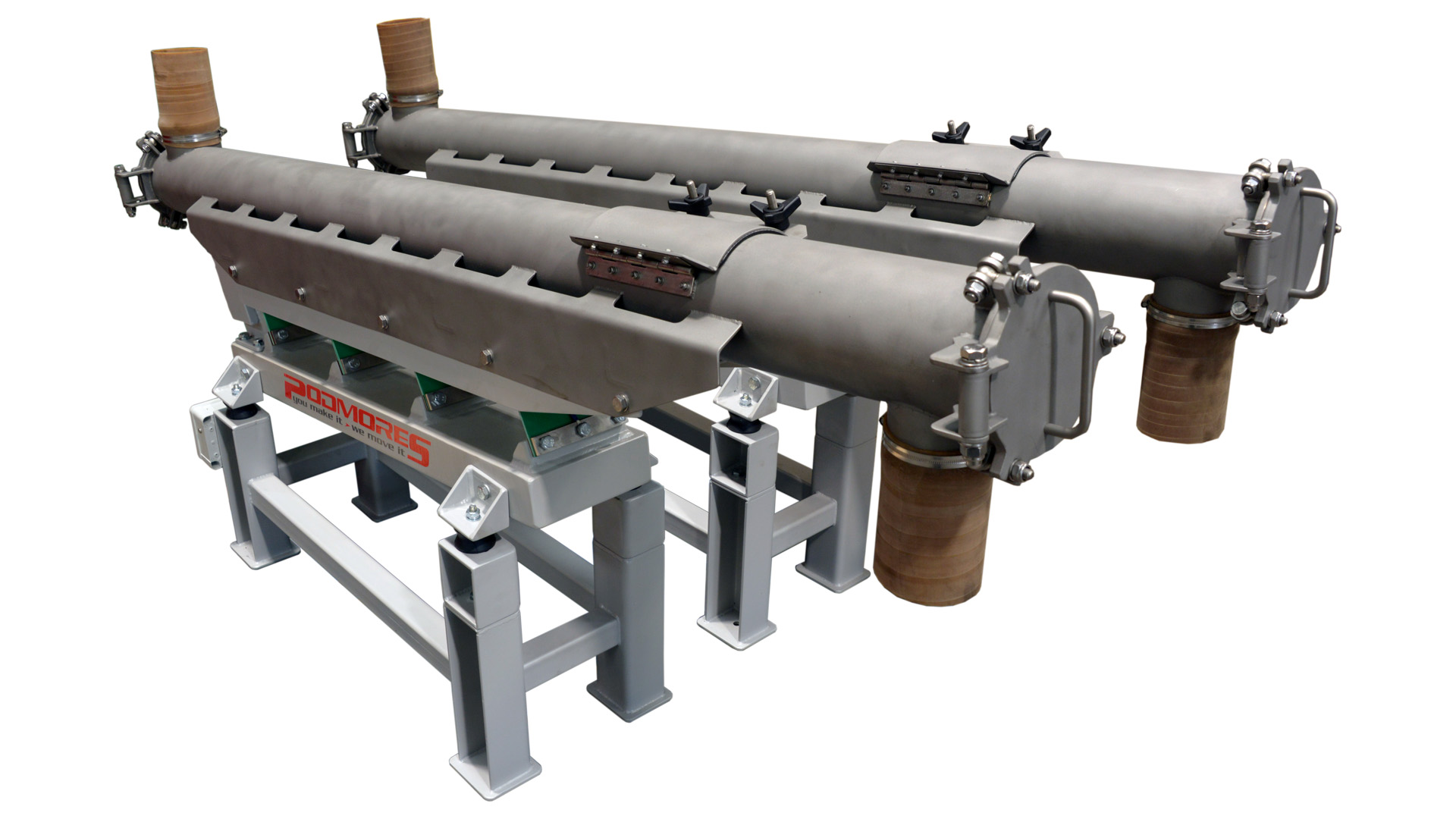

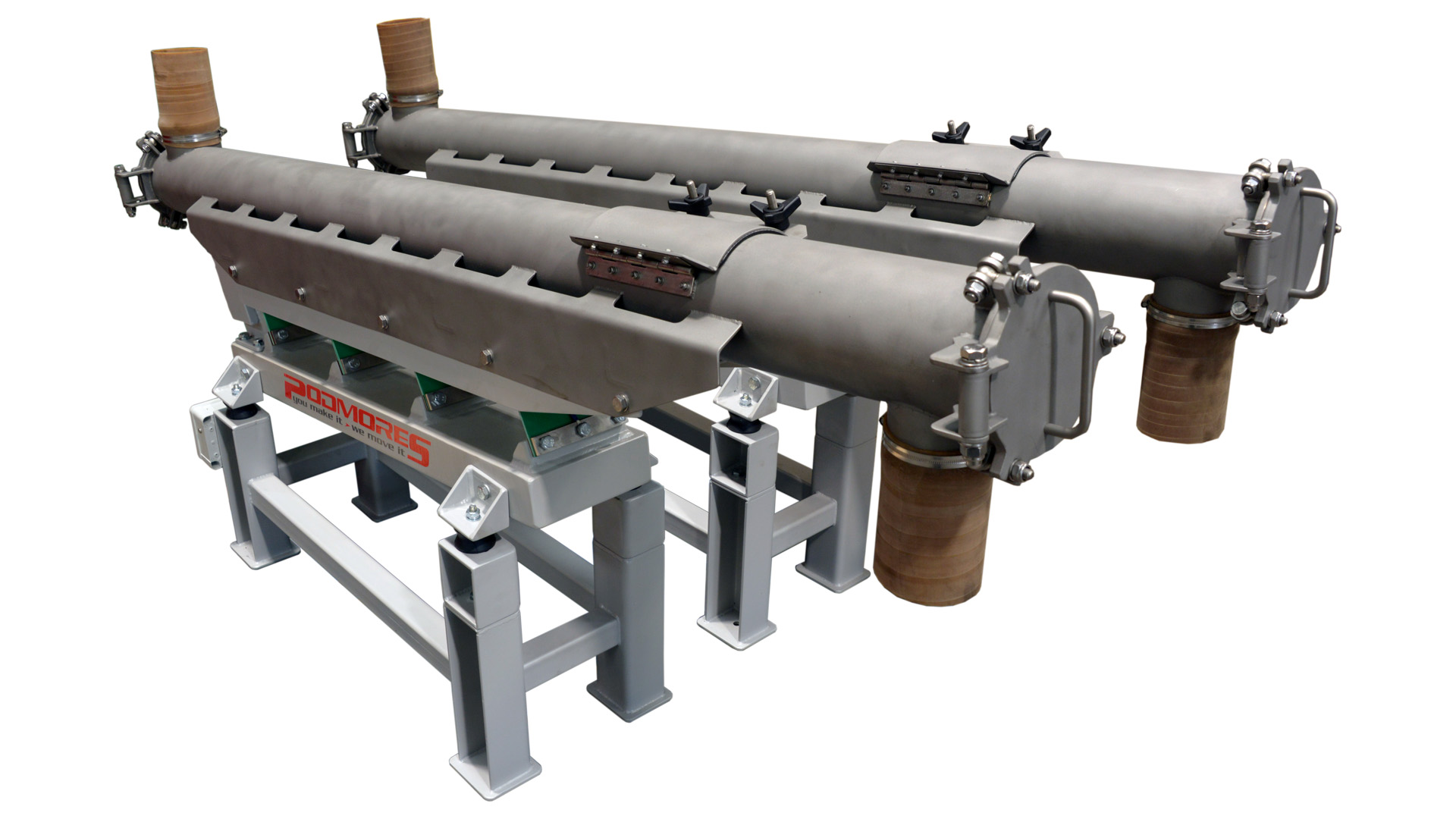

Totally enclosed tubular Vibratory Linear Feeders for the chemical/mineral industry with easy cleaning features.

Podmores have launched a new range of multi lane Counting Machines capable of high speed counting of individual or batches of parts. For applications where you are looking to count and deposit: Spoons, forks or Sporks

Podmores are delighted to announce the launch of our newly redesigned website at www.podmores-systems.com. The new site offers a consistent user experience across all devices with improved navigation and functionality, while enhancing the information available

Podmores have developed and manufactured a bespoke counting system capable of delivering mini pork pies into shelf ready packaging in various product configurations.

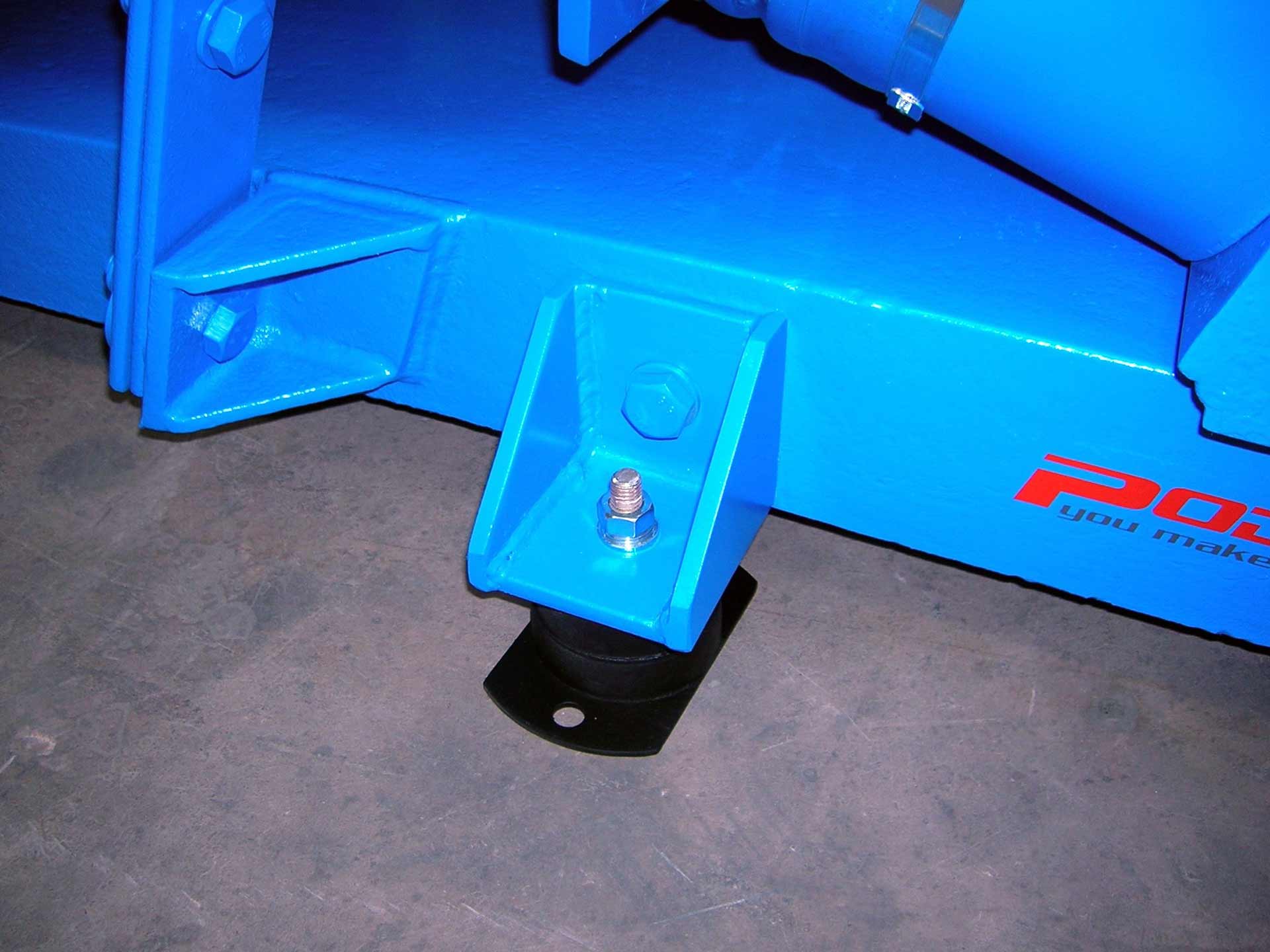

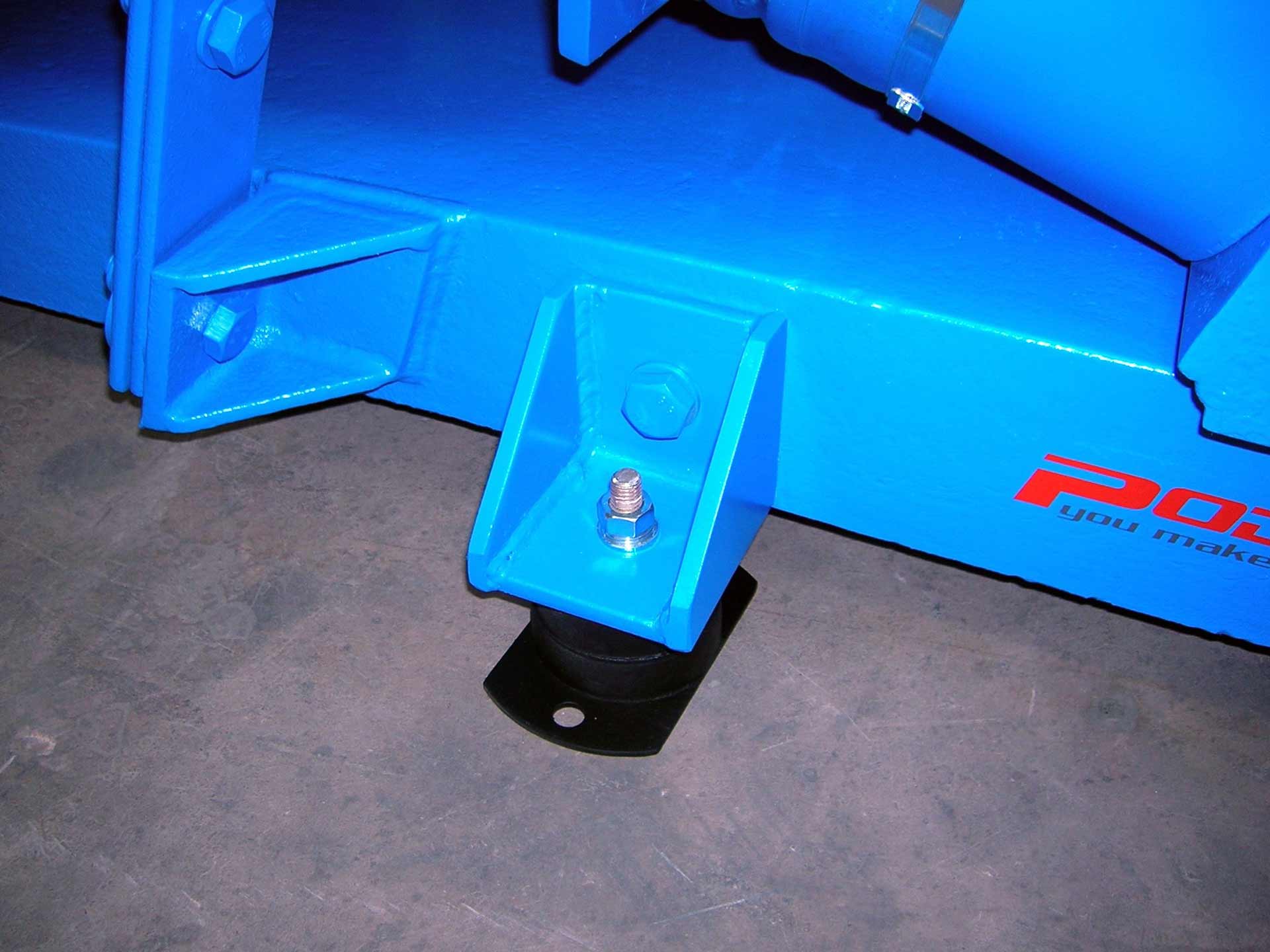

The following paint colours are available as standard for all painted (mild steel etc) parts: BS 48000 00E55 White RAL 9010 Pure White RAL 1014 Ivory RAL 7035 Light Grey RAL 9006 White Aluminium RAL

The super-deduction tax break means that you can claim 130% of what you spend on equipment for your business against taxable profits.

See Podmores’ range of Bowl Feeders and Conveyors in use at Walkers Pepsico – watch it on BBC iPlayer!

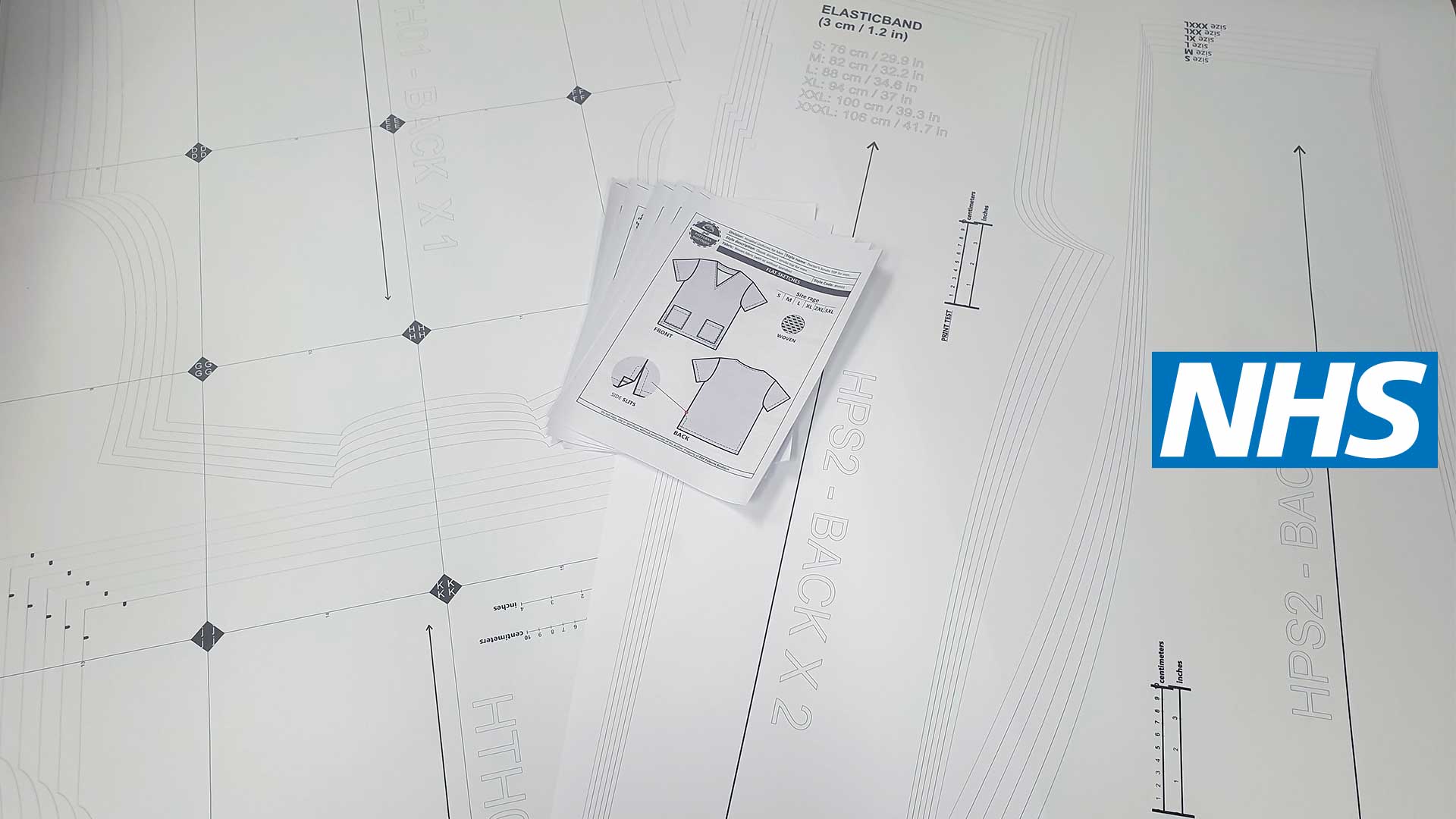

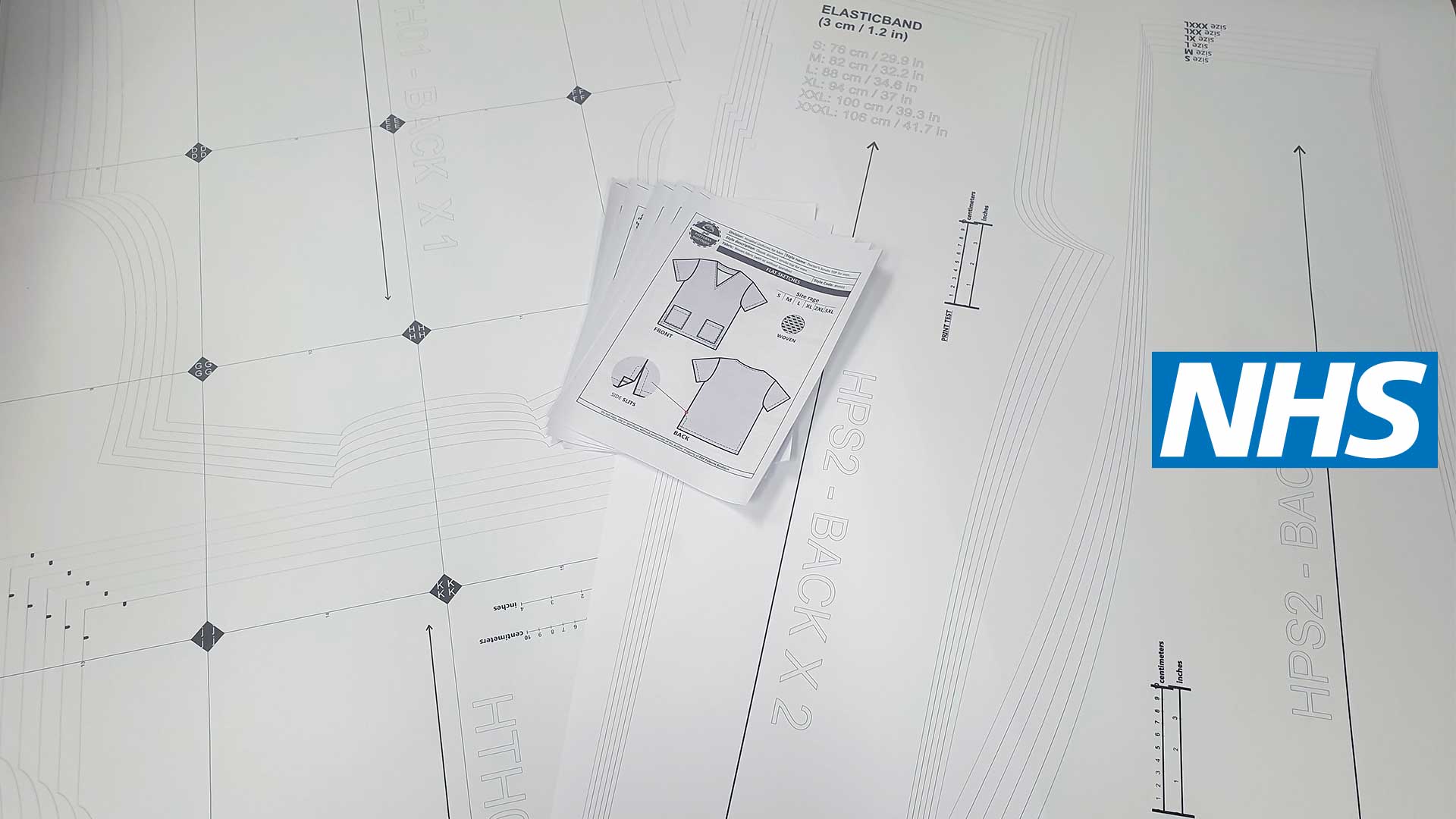

Can you sew or do you have an A0 printer? Join us in helping to make scrubs for the @NHSuk. We’ve printed 2 x the length of our factory in sewing patterns to help a local team hand making scrubs for the @NHSuk. https://ow.ly/LPBZ50zd6bW or DM us for more info on how you can help.

This is an update to our previous statement on 20th March 2020 in relation to the developing Covid-19 pandemic.

We’re looking forward to welcoming you to Podmores for our March Open Days. Please select a date and then a time below. What’s New High

A quick tour around our July 2023 Open Week demonstrating a range of new product solutions.

We’re looking forward to welcoming you to Podmores for our July Open Day. Please select a date and then a time below. What’s New Here

Podmores are delighted to announce that we are now a UK partner for Asyril. Asyril’s Asycube range of Flexible Feeders compliment perfectly Podmores’ range of

Knowing how your Vibratory Linear Feeder or Vibratory Bowl Feeder is performing is a critical part of any maintenance and performance monitoring process. Podmores have

Podmores are delighted to announce that our October 2022 Open Day registration is live. Book your place now!

Podmores are delighted to announce that our September 2022 Open Day registration is live. Book your place now!

Totally enclosed tubular Vibratory Linear Feeders for the chemical/mineral industry with easy cleaning features.

Podmores have launched a new range of multi lane Counting Machines capable of high speed counting of individual or batches of parts. For applications where

Podmores are delighted to announce the launch of our newly redesigned website at www.podmores-systems.com. The new site offers a consistent user experience across all devices

Podmores have developed and manufactured a bespoke counting system capable of delivering mini pork pies into shelf ready packaging in various product configurations.

The following paint colours are available as standard for all painted (mild steel etc) parts: BS 48000 00E55 White RAL 9010 Pure White RAL 1014

The super-deduction tax break means that you can claim 130% of what you spend on equipment for your business against taxable profits.

See Podmores’ range of Bowl Feeders and Conveyors in use at Walkers Pepsico – watch it on BBC iPlayer!

Can you sew or do you have an A0 printer? Join us in helping to make scrubs for the @NHSuk. We’ve printed 2 x the length of our factory in sewing patterns to help a local team hand making scrubs for the @NHSuk. https://ow.ly/LPBZ50zd6bW or DM us for more info on how you can help.

Get in touch

Podmores (Engineers) Ltd

Unit H Great Fenton Business Park, Grove Road, Stoke, Staffordshire,

ST4 4LZ, UK

Multihead Weigher Infeed

Gentle handling of product and optimised weighing through accurate delivery on demand

No spam, only occasional info about new products & updates.

We’re looking forward to welcoming you to Podmores for our March Open Days. Please select a date and then a time below. What’s New High

A quick tour around our July 2023 Open Week demonstrating a range of new product solutions.

We’re looking forward to welcoming you to Podmores for our July Open Day. Please select a date and then a time below. What’s New Here

Podmores are delighted to announce that we are now a UK partner for Asyril. Asyril’s Asycube range of Flexible Feeders compliment perfectly Podmores’ range of

Podmores will be closed from:

1200hrs Friday 23rd December 2022

until

0800hrs Tuesday 3rd January 2023

For emergency technical support please telephone the emergency contact number on your support plan documentation.

Merry Christmas & Happy New Year from everyone at Podmores.

Join us for our Open Days 21st-27th March, at our Stoke-on-Trent Factory (ST4 4LZ) See first-hand how our Teams’ skills and our range of products can help automate your production.