Gentle but powerful conveying of your product around your production processes, featuring rapid start/stop for responsive metering and a wide range of physical size and features to suit your needs.

| Frequency | 50Hz, 60Hz |

|---|---|

| IP Rating | IP54, IP65, IP66 |

| Materials | Aluminium, FDA Approved Plastics, FDA Rubber Lined, Mild Steel, Plastics, Rubber Lined, SS304, SS316L |

| Voltage | 110V, 230V, 415V |

Share

Learn more

Videos

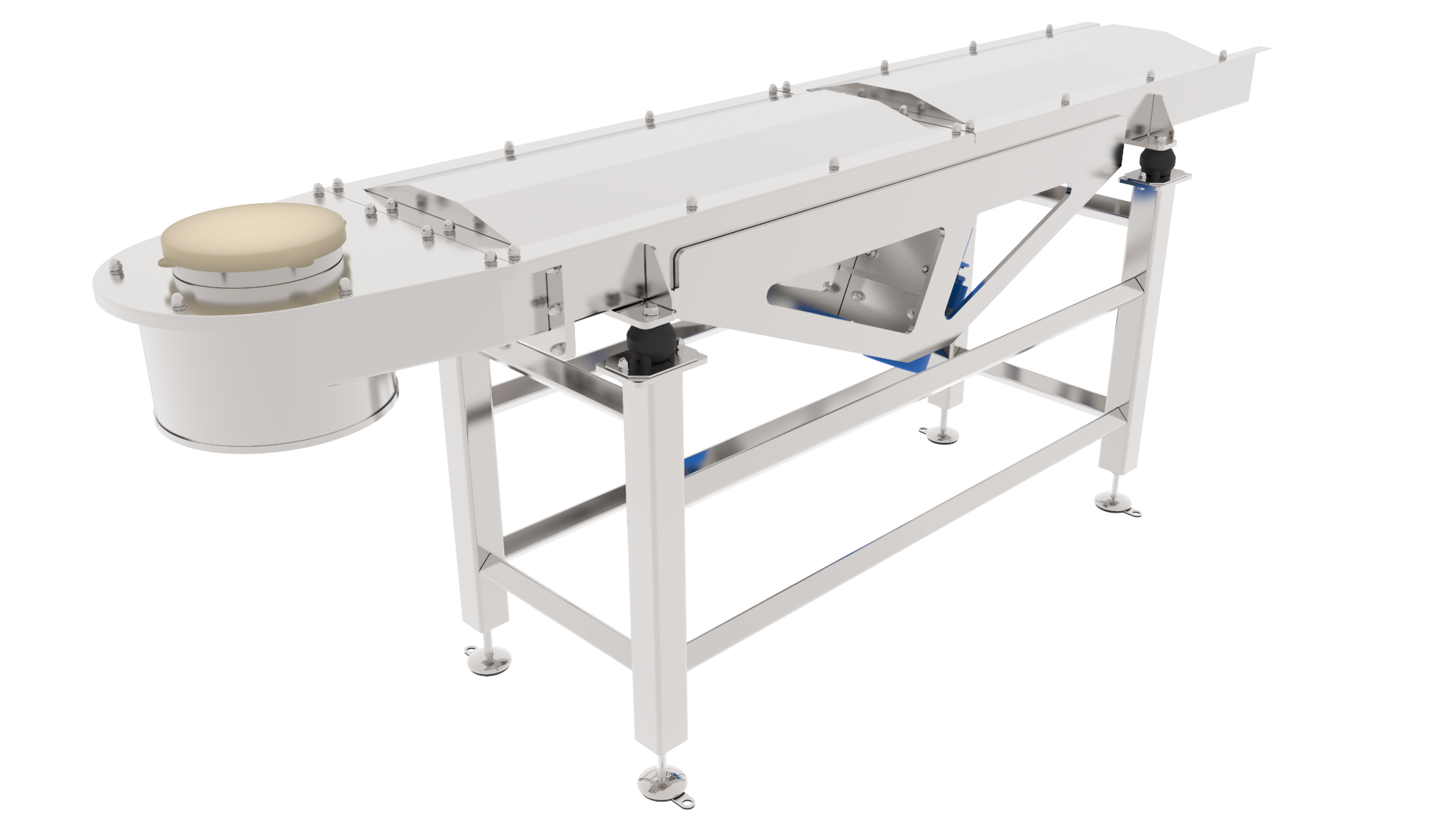

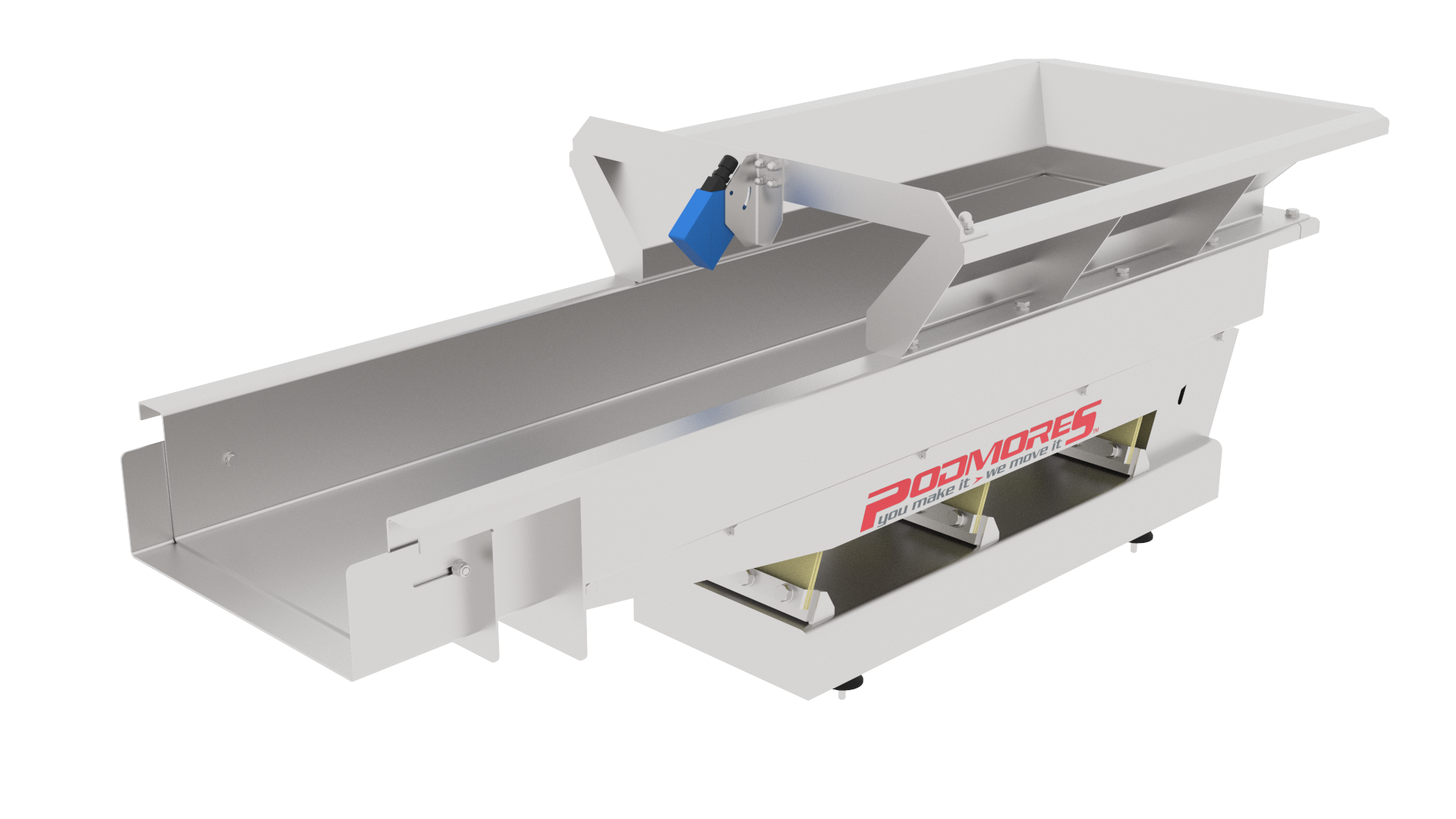

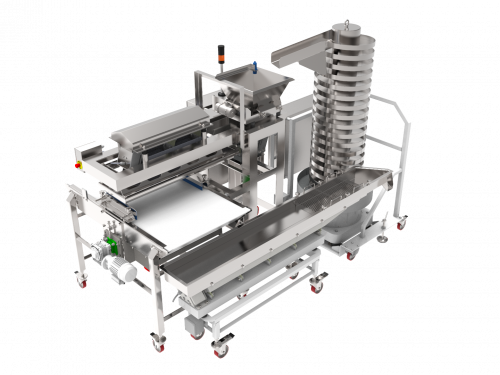

Vibratory Linear Feeders

Gentle but powerful conveying of product

Hygienic design for food applications and heavy duty range for demanding and challenging feeding projects.

Even Feeding

Ensure a full width delivery of product with spacing between each product

Variable Speed

Wide adjustment range with ability to lock off settings to prevent unauthorised access.

Infeed Solutions

Podmores offer a wide range of bulk storage infeed solutions to reduce operator refill times.

Reliable

Podmores offer an industry leading reliable design proven for 24/7/365 operation in critical process conditions.

Low Noise Level

The emission sound pressure level of our Linear Feeders is below 65 dB(A) at 1m distance, without product (Lpa re. 20µPa).

Low Running Cost

A basic Linear Feeder costs as little as £0.10 per hour in operation.

Easy to clean

No moving parts and our hygienic design mean an easy to clean machine suitable for raw food contact.

Customised Solution

Podmores offer a customised solution to your materials handling needs.

Want to find out more?

Applications

- Almost any component/product

- Dry, flowable ingredients

- Cereal

- Chocolate

- Cheese (including grated)

- Chewing gum

- Coffee

- Confectionary

- Fish

- Fruit

- Grains

- Inclusions & toppings

- Meat

- Nuts

- Pasta

- Pharmaceuticals

- Popcorn

- Powders

- Rice

- Seafood

- Seeds

- Snack Foods

- Tea

- Vegetables

- And more

Key benefits

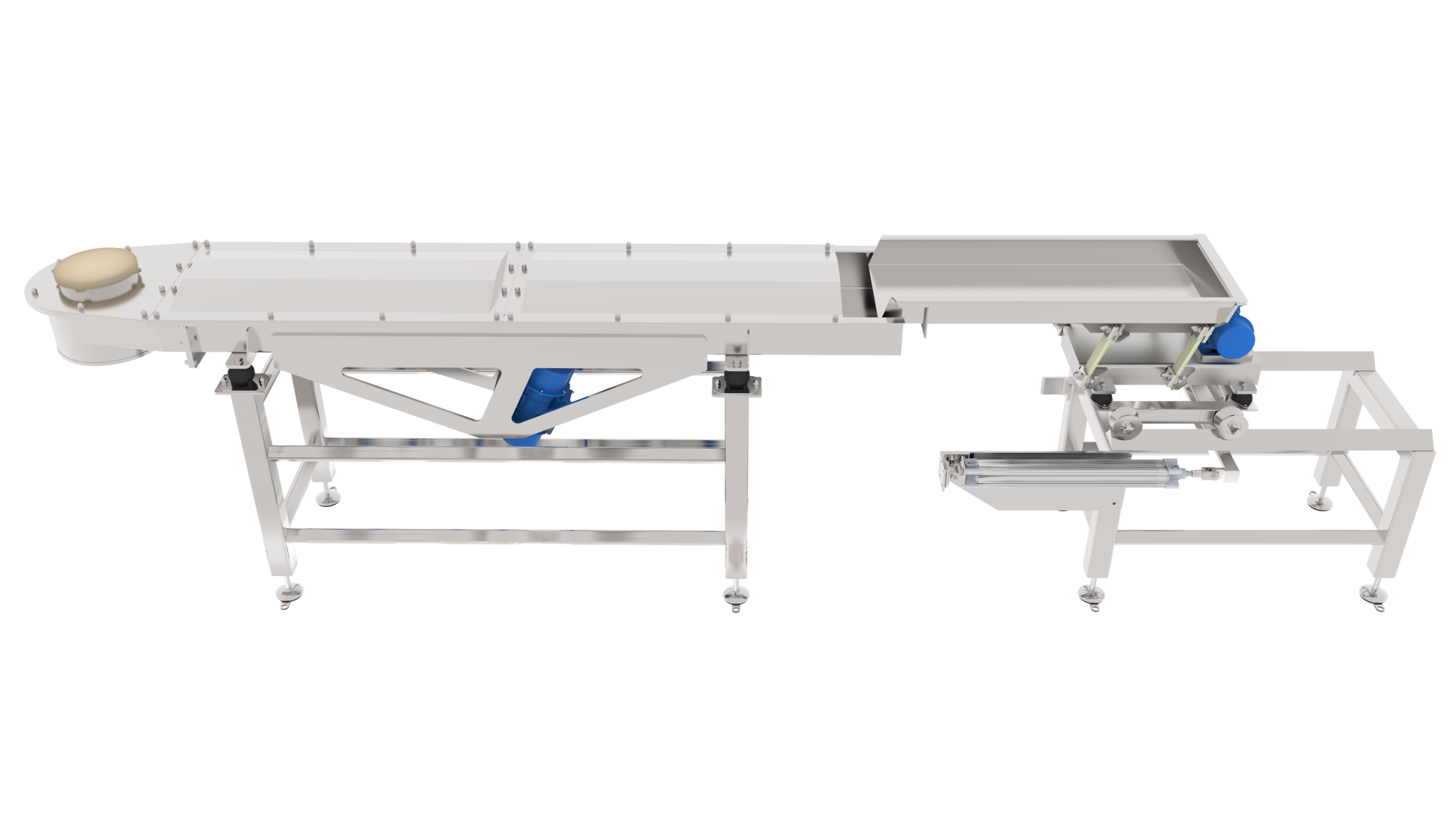

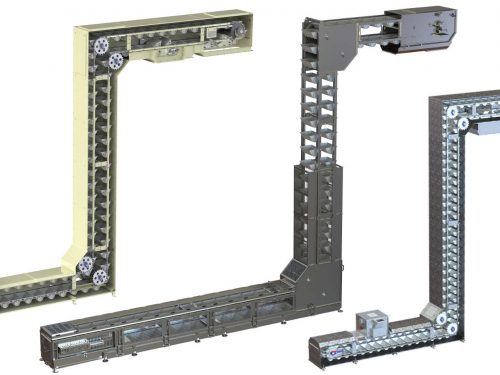

Podmores vibratory linear feeders/conveyors handle a variety of products, from the finest powders, or the smallest diamonds, to large quarry rocks. Our linear feeders and conveyors bridge the gaps between your existing manufacturing processes and provide you with the maximum control over your required feeding rates. Vibratory linear feeders and conveyors are manufactured in a wide range of shapes and sizes and many differing levels of finish and quality.

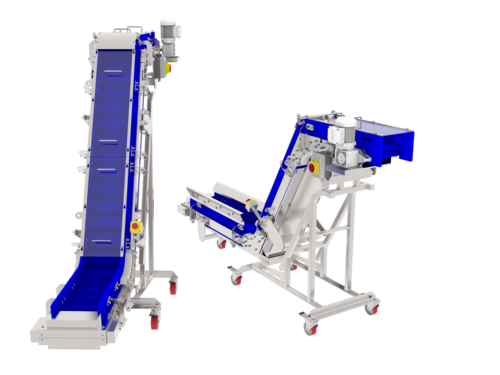

The instant start/stop functionality of our vibratory feeders means controlled infeeds are possible for demanding applications such as multihead weigher crosshead infeeds and high speed feeding applications.

The gentle vibration characteristic ensure your product isn’t damaged while being moved, no matter how fast it needs to be conveyed, ensuring the highest quality requirements are met.

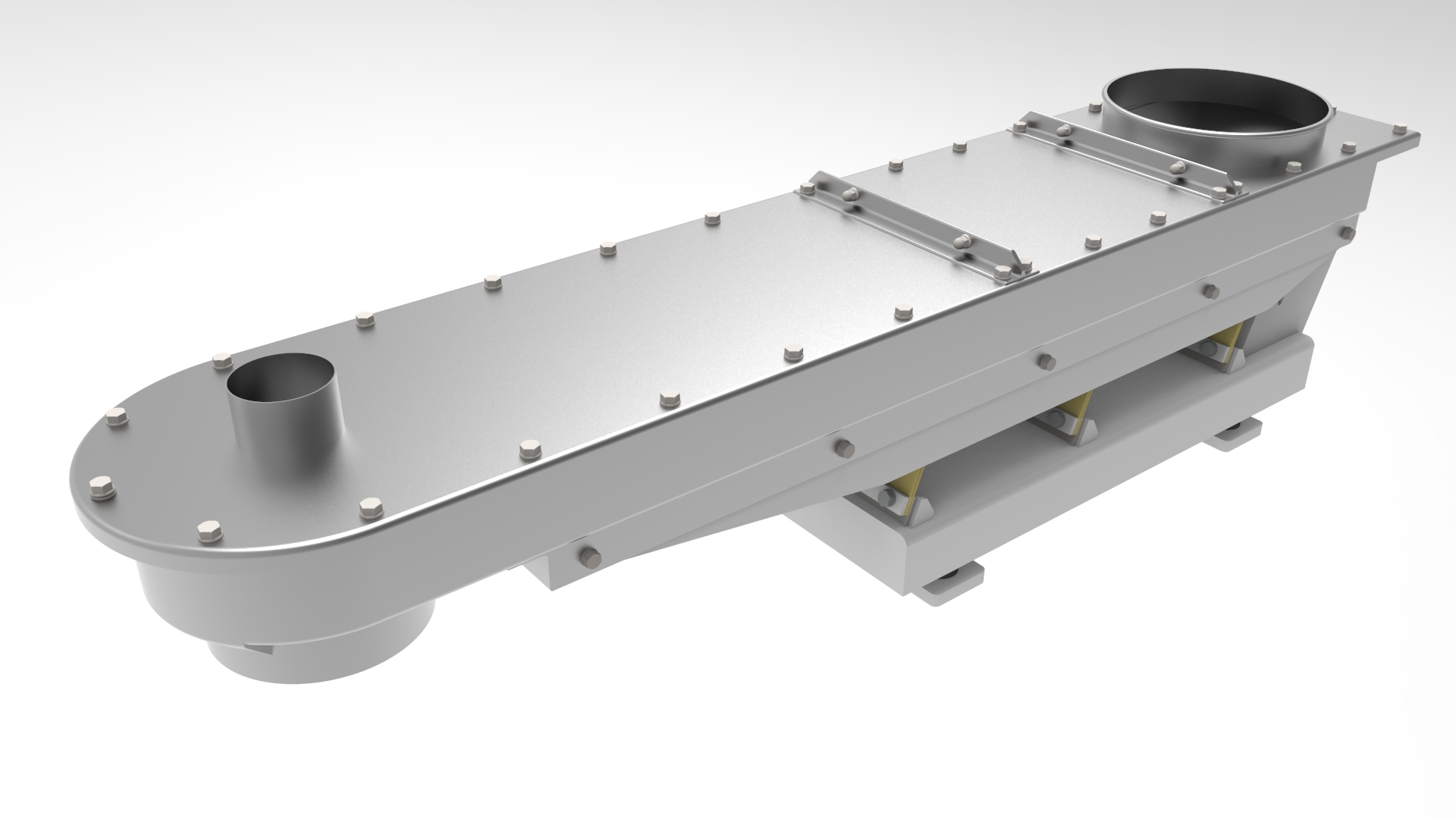

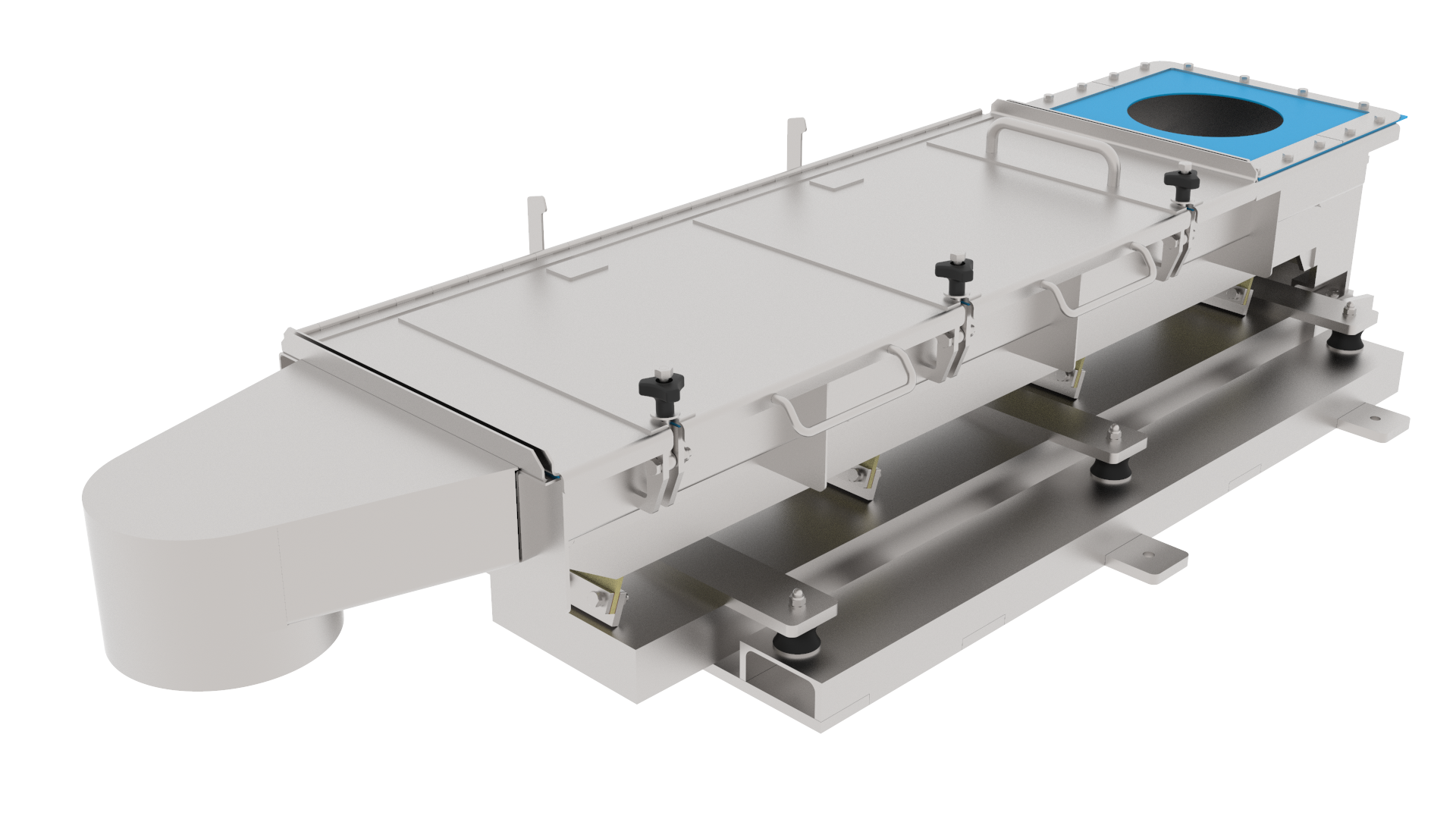

Available in high or low frequency varieties constructed out of stainless steel, mild steel or plastic trays; Podmores’ vibratory linear feeders and conveyors require minimal maintenance. Feeders can be left open or completely sealed and use dust-tight construction methods making them great for powders. Sound reduction can be incorporated into your vibratory linear feeders to reduce the impact of handling particularly noisy products.

- Crevice free washable conveying surface in the main feeder trays.

- Instant start/stop

- No moving parts.

- Constant feed rate that doesn't adjust over time.

- Compact design fits into existing production lines or new lines easily.

- Hygienic design and stainless steel contact materials.

- Vary speeds easily and simply.

- Quiet operation

- Optional hopper for product storage.

- Optional screening to remove small undersize or large oversize product.

- Static or mobile versions available.

- Quick return on investment (ROI)

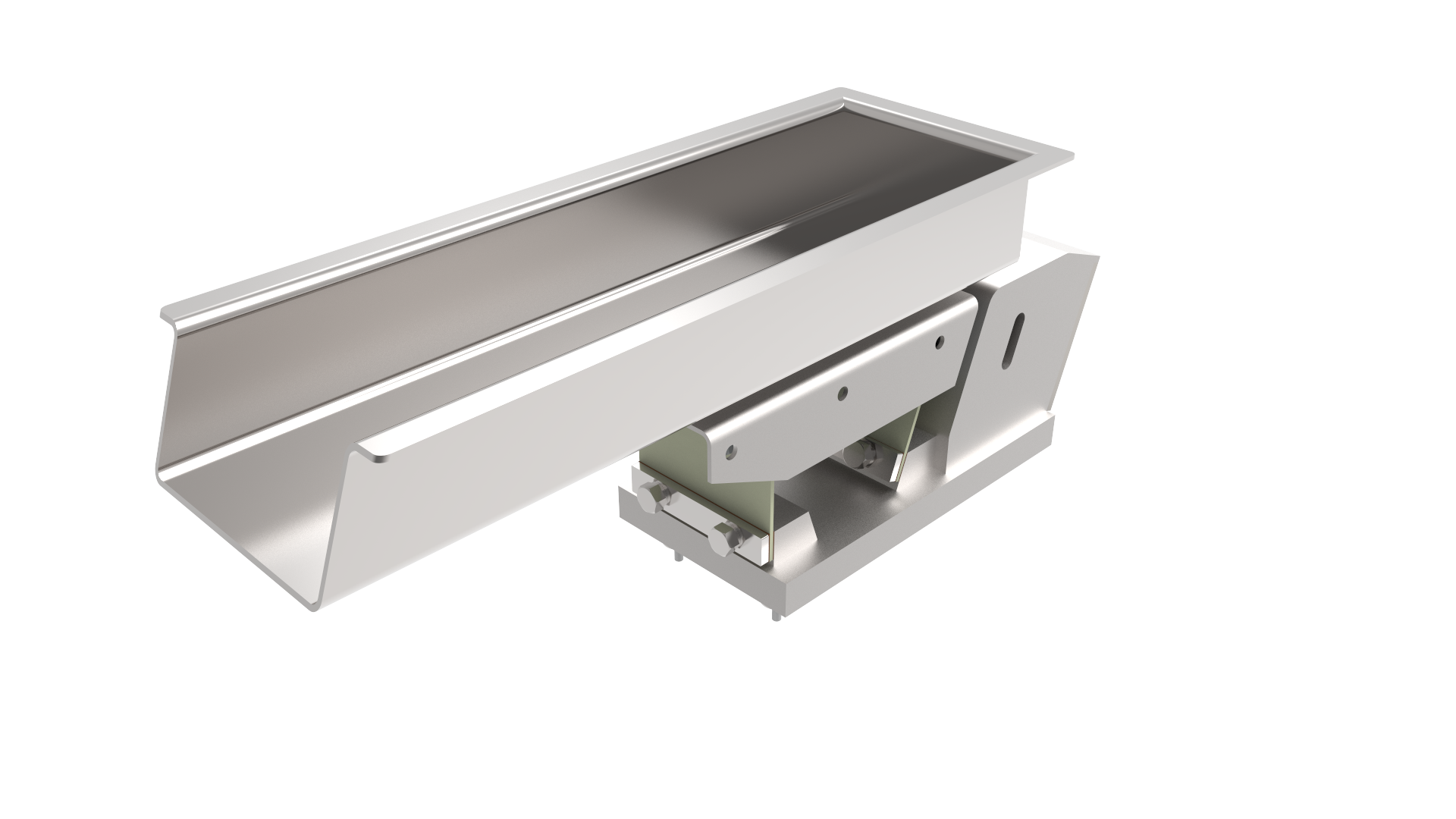

Optional infeed

skirt for product

buffer or hopper

for product storage

Tried & tested

vibratory feeder

drive units

A range of end

configurations to

suit your needs

Customisable

tray dimensions

Proven Technology

Podmores Vibratory Linear Feeders are found in factories all over the world, from small businesses to household name companies. Podmores Vibratory Linear Feeders have handled almost every product, providing product on demand to the next machine, and are trusted in critical production line processes. Their durable design means almost no downtime.

Even feed

Podmores vibratory linear feeders come tuned to get the best possible performance for your product. All products handle slightly differently and we use our 90 years of experience to get your vibratory linear feeder running evenly over the whole width. This makes our vibratory linear feeders excellent for feeding into other processes where you need to ensure a continuous supply of your product.

Gentle

Tried and tested with even the most gentle of products, our Vibratory Linear Feeders can successfully convey your product without creating any damage while not compromising on performance.

Spring into action

Podmores vibratory linear feeders use only a high-end epoxy fiberglass composite laminate material to provide the best performance. These springs have major advantages over coil springs such as increased life span, no gaps to get fingers stuck in, less noise. When stopping the machine, laminated springs also provide almost no ‘wobble’ whereas coil springs will continue to move in the path they were vibrating until they come to a natural stop.

Want to find out more?

Controllers

Metal finishes

Electromagnetic Coils

Hygienic Design

ATEX

Get in touch

Contact Us

ADDRESS

Podmores (Engineers) Ltd

Unit H Great Fenton Business Park, Grove Road, Stoke, Staffordshire,

ST4 4LZ, UK

Solving automation problems since 1930