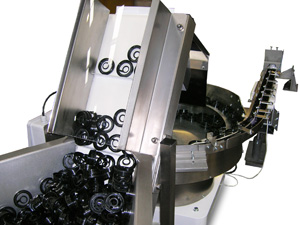

Podmores have developed a bespoke Bowl Feeder to handle a new design of easy-open plastic lids, soon to enter the market place for a leading high street retailer. The bespoke Bowl Feeder system developed by Podmores includes a hopper unloader and a vibratory bowl feeder capable of feeding two sizes of plastic lid onto an induction capping machine with sensors to link the two elements together.

Podmores have developed a bespoke Bowl Feeder to handle a new design of easy-open plastic lids, soon to enter the market place for a leading high street retailer. The bespoke Bowl Feeder system developed by Podmores includes a hopper unloader and a vibratory bowl feeder capable of feeding two sizes of plastic lid onto an induction capping machine with sensors to link the two elements together.

The bowl feeder is a 304 stainless steel fabricated unit suitable for food industry use and will orientate the two sizes of lids at a rate of 30 per minute. The stainless steel discharge chute was specifically designed so as to allow both sizes to be orientated with minimal alteration when swapping sizes. As the machine was to integrate with an existing capping process Podmores fitted sensors and pneumatic gates to the discharge chute so that a lid would only be released when requested by the capping machine. The hopper unloader had a large storage capacity allows an operator to easily and safely fill it with lids to be sorted and not have to re-fill too often. The belt was a non-marking food grade variety which gently raises the lids up into the bowl feeder to keep it full.

Mike Sherwin, Sales Manager for Podmores said: ‘Podmores’ experience with handling unusual or completely new types of components made it perfectly suited to this job. We were able to use our extensive knowledge to design and manufacture a system with a small footprint which seamlessly linked up to the customer’s existing process. We kept food-hygiene standards in mind at all times and as there would be numerous staff working around it produced a machine which is totally suited to a position where there is no separation between staff and machinery’.

Mike Sherwin, Sales Manager for Podmores said: ‘Podmores’ experience with handling unusual or completely new types of components made it perfectly suited to this job. We were able to use our extensive knowledge to design and manufacture a system with a small footprint which seamlessly linked up to the customer’s existing process. We kept food-hygiene standards in mind at all times and as there would be numerous staff working around it produced a machine which is totally suited to a position where there is no separation between staff and machinery’.

This bespoke system was specially designed for this application but similar systems can also be developed to handle products for the following industries: aerospace, automotive, chemicals, cosmetics, electronics, food & beverage, medical & biotech, military, mining, packaging, pharmaceutical, plastics & recycling.

For more information, please contact us.