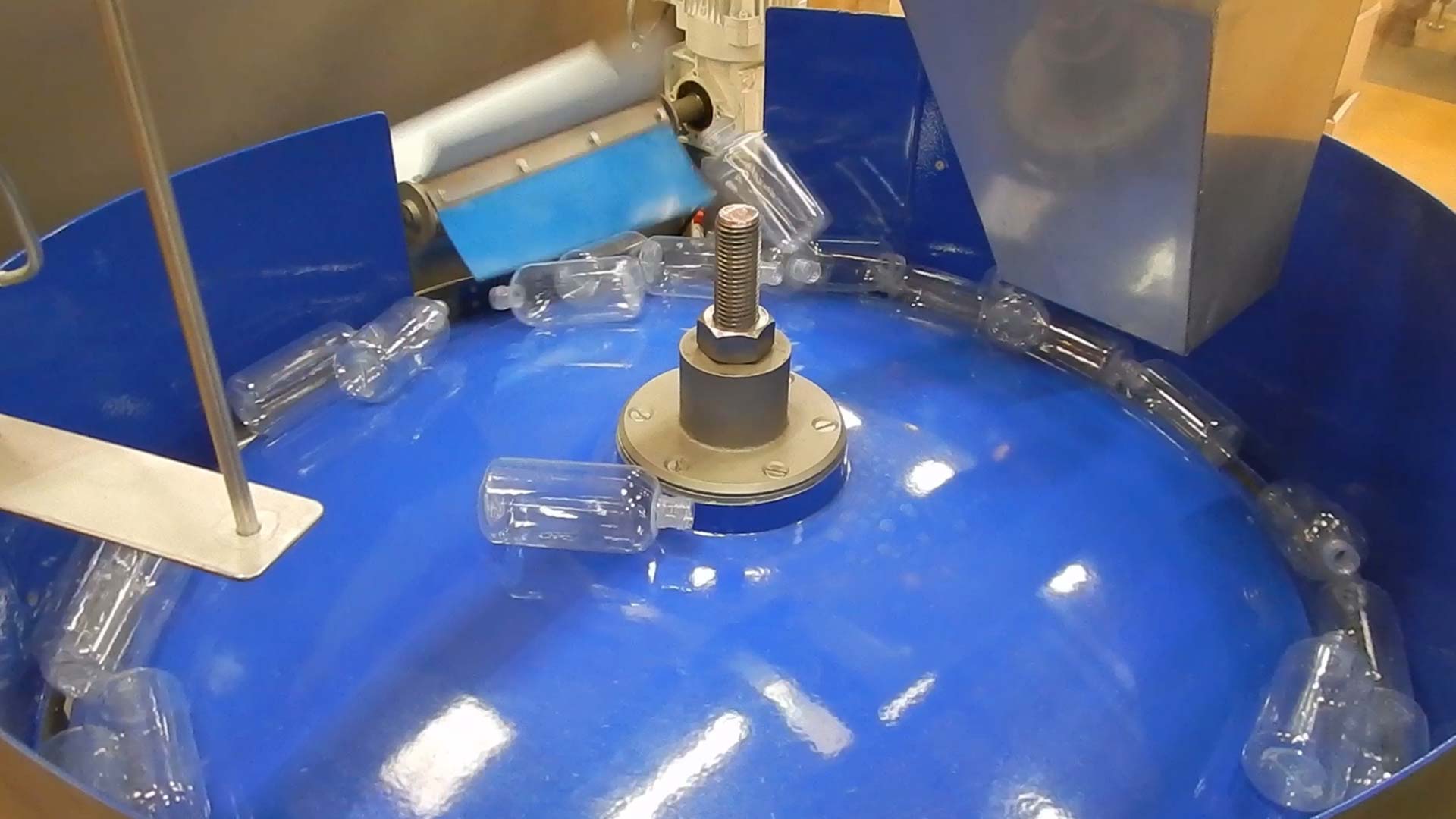

Turn a box full of your bottles into an ordered, orientated stream of bottles quickly and efficiently with our bottle unscramblers. Suitable for bottles of all sizes, we can manufacture a machine which will sort your bottles into whatever orientation you want.

| Frequency | 50Hz, 60Hz |

|---|---|

| IP Rating | IP54, IP65, IP66, IP67, IP68 |

| Materials | Aluminium, FDA Approved Plastics, FDA Rubber Lined, Mild Steel, Plastics, Rubber Lined, SS304, SS316L |

| Voltage | 110V, 230V, 415V |

Share

Learn more

Sort and unscramble bottles quickly and gently

Economical sorting solutions with simple operation and minimal maintenance.

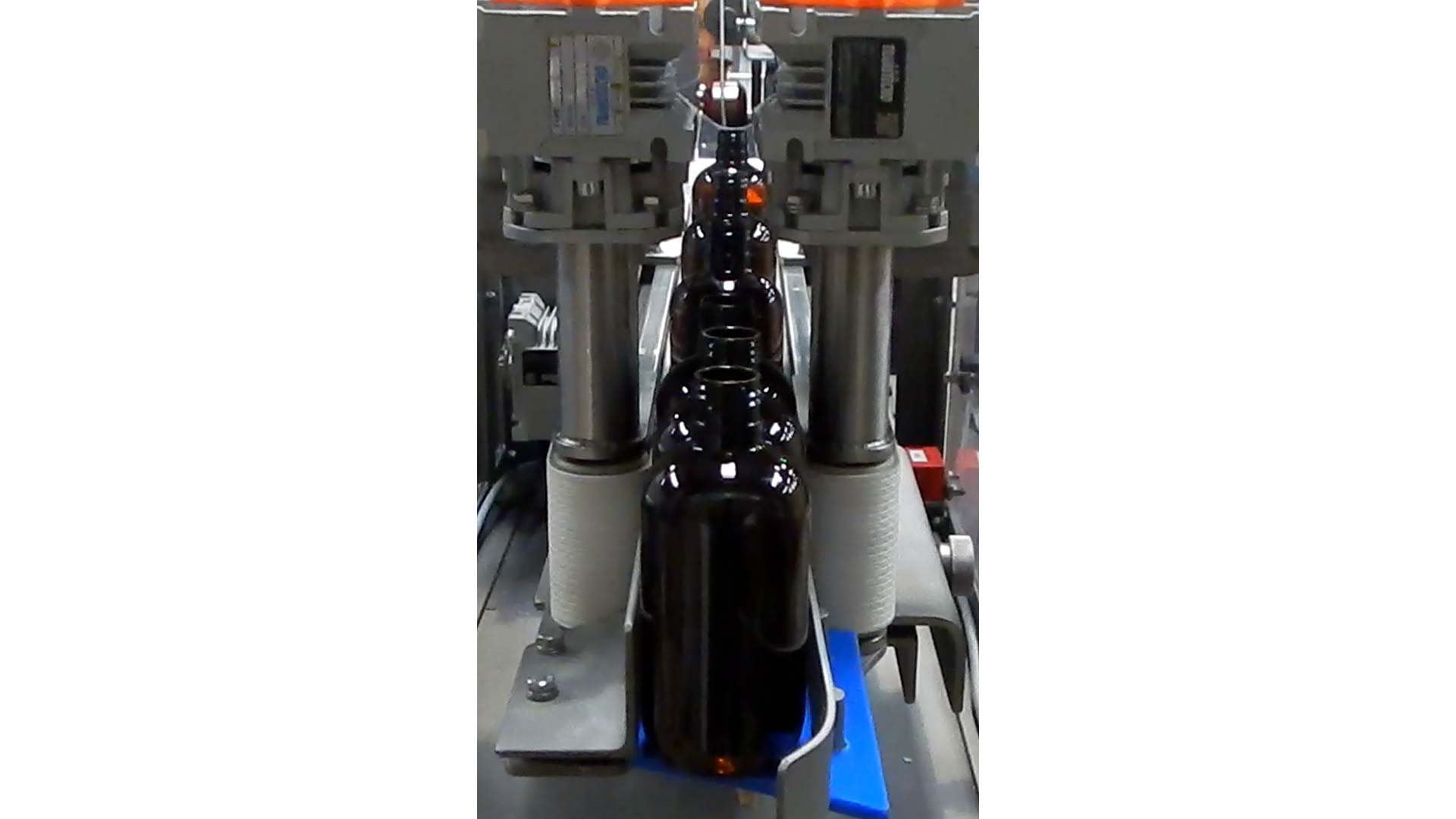

Consistent orientation

Ensure all bottles are correctly orientated for your next process.

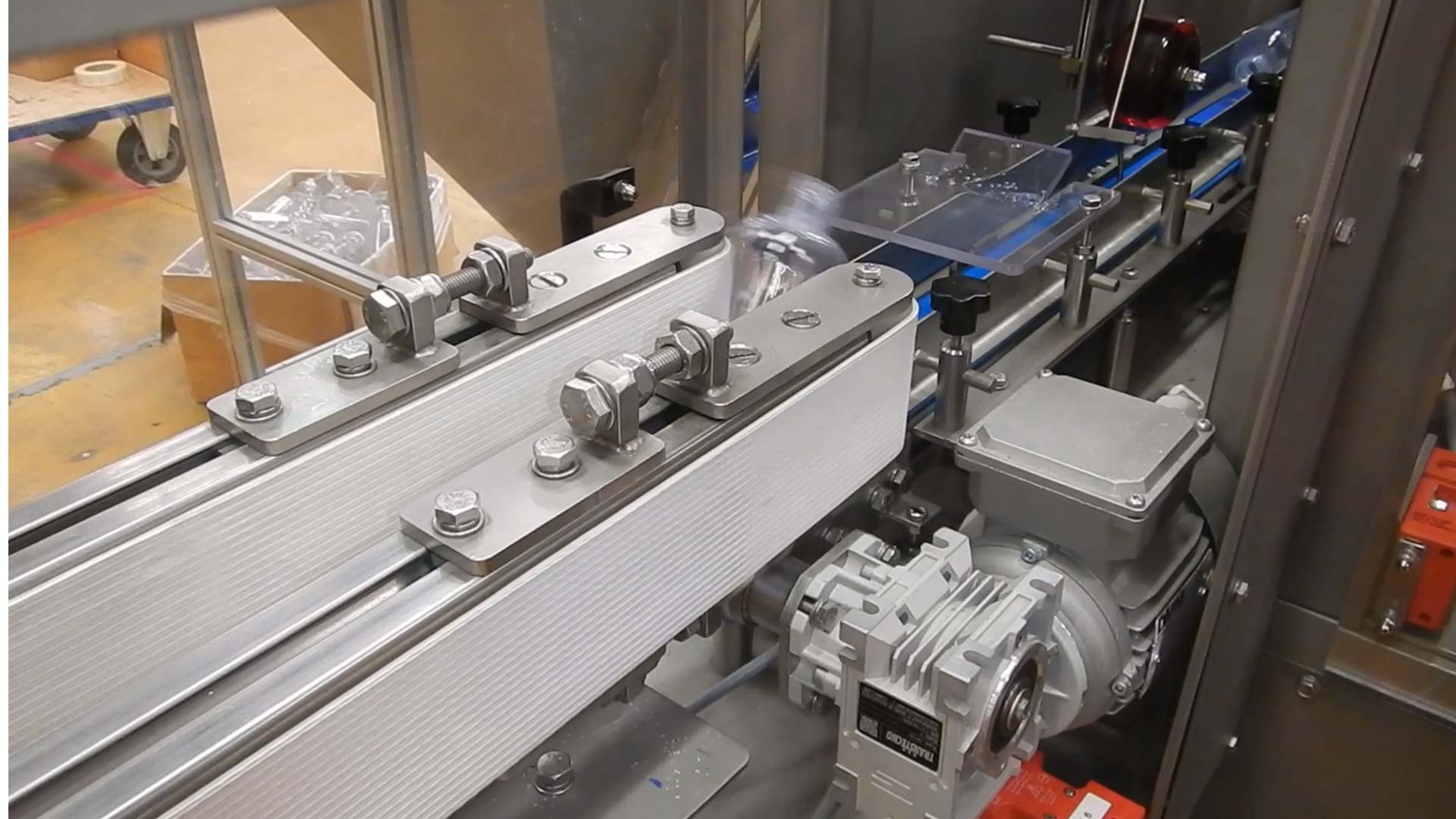

Adjustable

A range of mechanical and electrical adjustments can be included for different bottle formats

Infeed Solutions

Podmores offer a wide range of bulk storage infeed solutions to reduce operator refill times.

Reliable

Podmores offer an industry leading reliable design proven for 24/7/365 operation in critical process conditions.

Low Noise Level

The emission sound pressure level of our standard Bottle Unsrambler is below 65 dB(A) at 1m distance, without product (Lpa re. 20µPa).

Low Running Cost

A basic Bottle Unscrambler costs as little as £0.20 per hour in operation.

Easy to clean

Hygienic design options available mean an easy to clean machine suitable for washdown environments.

Customised Solution

Podmores offer a customised solution to your materials handling needs.

Want to find out more?

Applications

- Bottles

- Jars

- Pots

- And more

Key benefits

Podmores’ Bottle Unscramblers gently sort your bottles, without marking or damaging leaving you without quality control issues. Suitable for food and drink applications we make our machinery to the highest standard. Our range of Bottle Unscramblers are perfectly suited to food and non-food applications where a reliable and consistent supply of correctly orientated bottles is required.

- Quickly sort bottles to any orientation

- Simple operation without jams or interuptions

- No marking or damage to the bottles

- Continuous stream or on demand output

- Compact design fits into existing production lines or new lines easily.

- Hygienic design and stainless steel contact materials.

- Optional hopper for product storage.

- Static or mobile versions available.

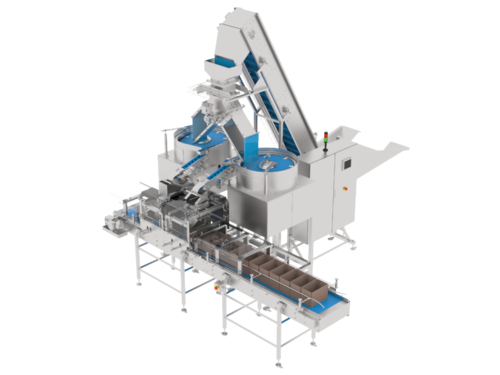

Hopper Elevator to store

product, freeing up

operators for other tasks

Twin belt outfeed

conveyor to

transfer to

next machine

Bottle unscrambler

within interlocked

enclosure

Control Panel can

be local mounted,

above/below or

remotely mounted

Proven Technology

Podmores Laning Feeders are found in factories all over the world, from small businesses to household name companies. Podmores Laning Feeders provide the nuts, chocolates and confectionary for enrobing, sausages, burgers, prawns and fish for robot picking and much more, and are trusted in critical production line processes. Their durable design means almost no downtime.

Controlled

Deliver bottles to the next process correctly aligned/orientated and ready for filling.

Fill and forget

Our expertise with Storage & Infeed Systems allows us to deliver a solution no matter how much product you want to hold and how little you want to have to top the system up. Podmores can help you deploy storage solutions that keep your operatives free for other tasks around your factory.

Want to find out more?

Controllers

Spacing

Output

Hygienic Design

ATEX

Get in touch

Contact Us

ADDRESS

Podmores (Engineers) Ltd

Unit H Great Fenton Business Park, Grove Road, Stoke, Staffordshire,

ST4 4LZ, UK

Solving automation problems since 1930