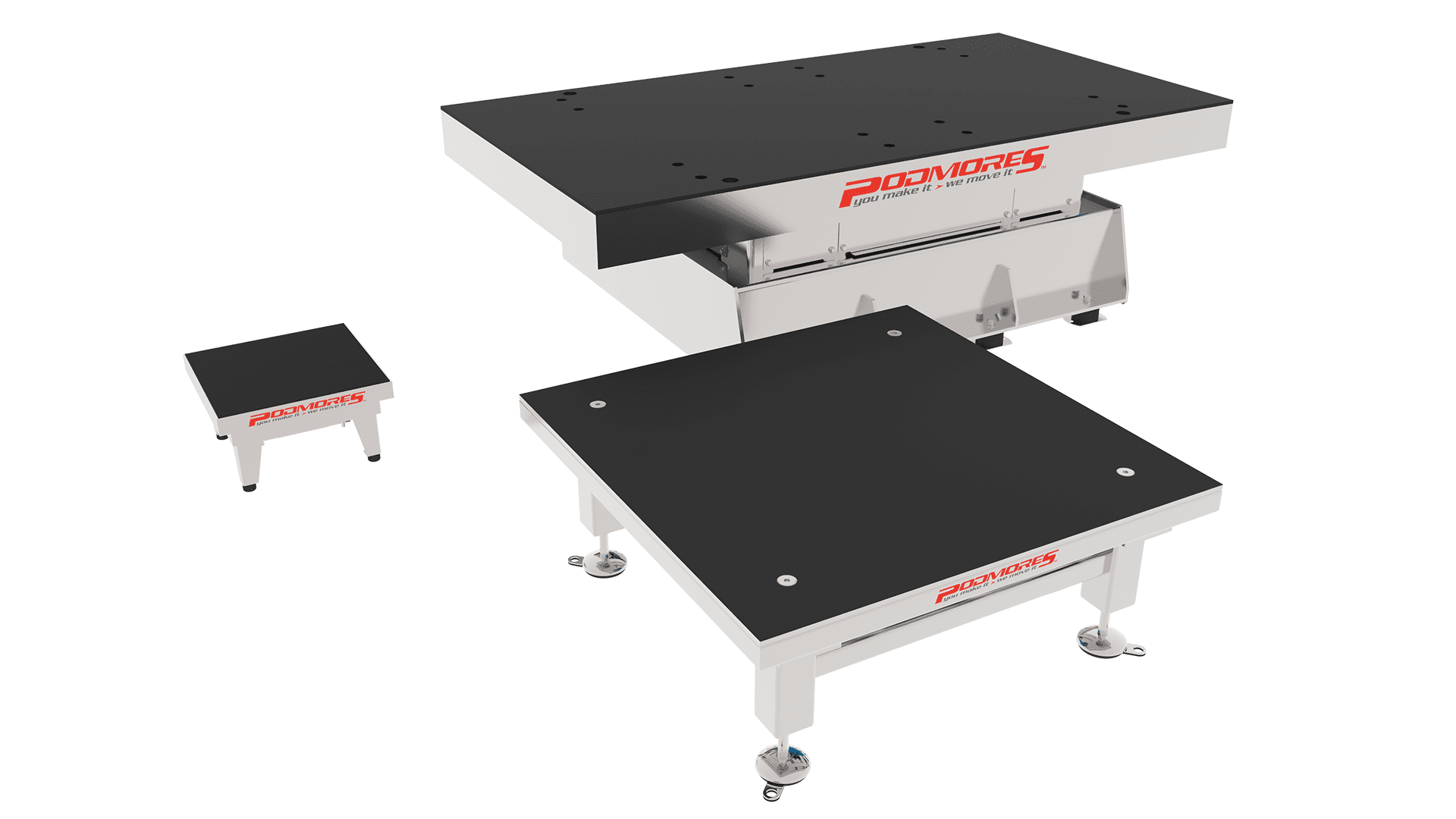

Podmores vibratory compaction tables provide a quick, simple and efficient method of compacting almost any product. Available with a flat top or in a custom design to suit your specific application, our vibratory compaction tables can help your bulk materials handling requirements.

| Frequency | 50Hz, 60Hz |

|---|---|

| IP Rating | IP54, IP65, IP66, IP67, IP68 |

| Materials | Aluminium, FDA Approved Plastics, FDA Rubber Lined, Mild Steel, Plastics, Rubber Lined, SS304, SS316L |

| Voltage | 110V, 230V, 415V |

Share

Learn more

Videos

Vibratory Compaction Tables

Compact, settle and mix your product

Get up to 30% more into your FIBC big bags by compacting your product!

Use space better

Settle peaked loads and fill every possible area of space

Big savings

Get up to 30% more into a FIBC 'big bag', making transport and storage more economical

Pallet Connection

Load pallets to settle loads in pallet based containers

Mix it up

Load barrels/containers to mix liquids or remove air from mouldings by vibrating them up & out

Low Noise Level

The emission sound pressure level of our smallest Vibratory Compaction Table is below 65 dB(A) at 1m distance, without product (Lpa re. 20µPa).

Low Running Cost

A basic Vibratory Compaction Table costs as little as £0.20 per hour in operation.

Reliable

Podmores offer an industry leading reliable design proven for 24/7/365 operation in critical process conditions.

Customised Solution

Podmores offer a customised solution to your materials handling needs.

Want to find out more?

Applications

- Bulk materials

- Castings

- Dry, flowable ingredients

- FIBC 'Big Bags'

- Liquids

- Mouldings

- Paint

- Palletised containers

- And more

Key benefits

Podmores Vibratory Compaction Tables provide a quick, simple and efficient method of compacting almost any product. Available with a flat top or in a custom design to suit your specific application, our vibratory compaction tables can help your bulk materials handling requirements.

What makes Podmores Vibratory Compaction Tables unique is the ability to have a machine tailor made to your requirements, and through using additional features such as automatic starters which sense when a load is added and start the machine, then shut it off on a timer.

- Quickly compact your product.

- Low profile for easy manual handling.

- Noise reduction surface available.

- Automatic or remote controlled start available.

- Simple maintenance.

Smallest size

400mm x 400mm

Largest size

2,000mm x 1,000mm

Fastening points for

you to mount

clamping attachments

Rubber lined

top to reduce

noise in operation

Proven Technology

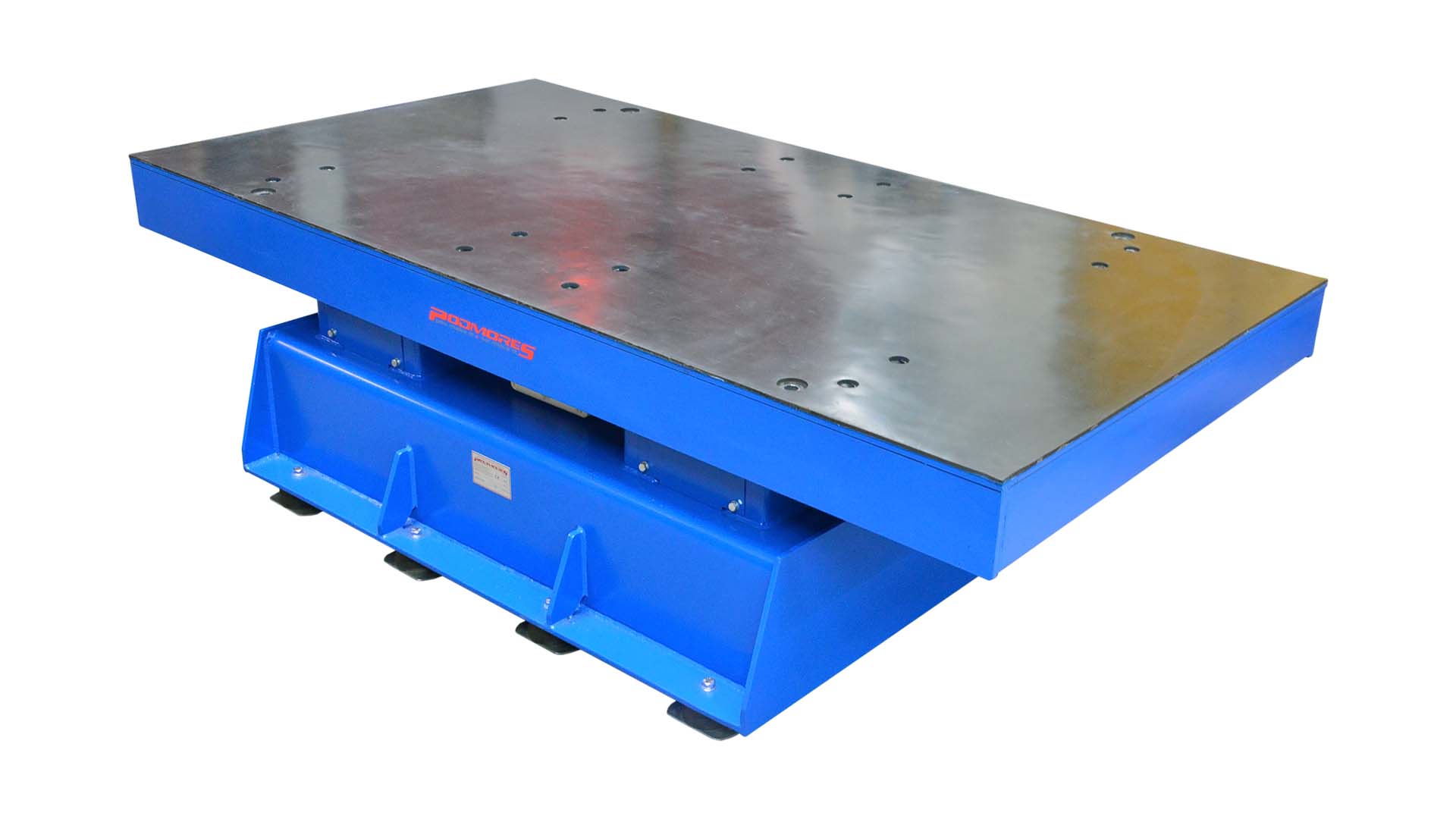

Podmores Vibratory Compaction Tables are found in factories all over the world, from small businesses to household name companies. Podmores Vibratory Compaction Tables provide significant reductions in transportation and storage costs for bulk containers by better utilising the volume available through settling product efficiently. Their durable design means almost no downtime.

Safe to touch

This Podmores machine has no accessible moving parts making it perfect for use in and around operators. Unlike many similar products you can operate and work around this machine safely and without having to take added precautions when loading the machine.

Vibration isolation

The machine sits on anti-vibration mountings which isolate the vibration from the machine from the floor. Podmores use high quality anti-vibration mountings to ensure safety and comfort for operators. By isolating the vibration this machine can also be situated around other machinery which may be sensitive to vibration without any problems.

Noise reduction surface

Our expertise with Storage & Infeed Systems allows us to deliver a solution no matter how much product you want to hold and how little you want to have to top the system up. Podmores can help you deploy storage solutions that keep your operatives free for other tasks around your factory.

Lifting/loading points

Our Heavy Duty Vibratory Tables (HDFV series) can be fitted with eye-bolts for easy lifting. They also feature forklift lifting points. Each machine comes with an instruction manual which includes details of how to safely move the machine by a variety of methods.

Want to find out more?

Controllers

ATEX

Get in touch

Contact Us

ADDRESS

Podmores (Engineers) Ltd

Unit H Great Fenton Business Park, Grove Road, Stoke, Staffordshire,

ST4 4LZ, UK

Solving automation problems since 1930