Laning Feeders can be used to deliver discrete lanes of product to downstream processes, such as enrobering machines, robots baggers. Our laning machines are tailored to your specific requirements to achieve your desired product positioning.

| Frequency | 50Hz, 60Hz |

|---|---|

| IP Rating | IP54, IP66, IP67, IP68 |

| Materials | Aluminium, FDA Approved Plastics, FDA Rubber Lined, Mild Steel, Rubber Lined, SS304, SS316L |

| Voltage | 110V, 230V, 415V |

Share

Learn more

Optimising downstream product delivery

Deliver product in the correct position for robot picking or enrobing with gaps around each product.

Even Feeding

Ensure a full width delivery of product with spacing between each product

Variable Speed

Wide adjustment range with ability to lock off settings to prevent unauthorised access.

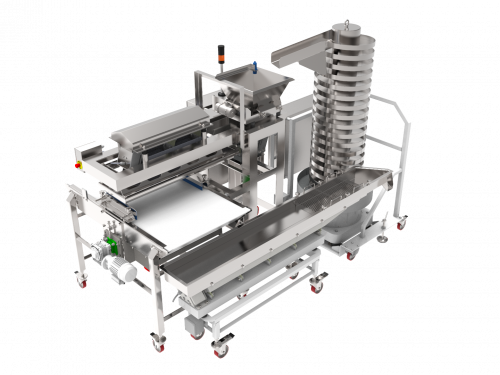

Infeed Solutions

Podmores offer a wide range of bulk storage infeed solutions to reduce operator refill times.

Reliable

Podmores offer an industry leading reliable design proven for 24/7/365 operation in critical process conditions.

Low Noise Level

The emission sound pressure level of all our Laners is below 65 dB(A) at 1m distance, without product (Lpa re. 20µPa).

Low Running Cost

A basic Laner costs as little as £0.20 per hour in operation.

Easy to clean

No moving parts and our hygienic design mean an easy to clean machine suitable for raw food contact.

Customised Solution

Podmores offer a customised solution to your materials handling needs.

Want to find out more?

Applications

- Almost any component/product

- Burgers

- Candy pieces

- Chicken pieces (including breaded)

- Dry, flowable ingredients

- Enrobed products

- Fish

- Meat

- Nuts

- Robot picked parts

- Seafood

- Sausages

- And more

Key benefits

Podmores Vibratory Laning Feeders have been specially developed to help you achieve your quality requirements with minimal operator assistance. Featuring an easy to operate control you can simply adjust to achieve the optimum delivery of product for your requirements.

Our laning solutions are perfect for feeding enrobing conveyors, making sure products aren’t too close together so that they don’t fuse during enrobing, creating wastage.

They are also the perfect solution for robot picking belt infeed because they create an even and distributed supply of product for the vision system to see clearly the outline of each product.

With a Podmores Laning Feeder you can improve your quality, reduce wastage and better utilise labour by removing the need for a repetitive manual operation.

- Vary speeds easily and simply.

- Creates even and consistent lanes of product.

- Interchangeable laning decks allow for quick product format changeover and future proof the machine for new products.

- Constant feed rate that doesn't adjust over time.

- Compact design fits into existing production lines or new lines easily.

- Hygienic design and stainless steel contact materials.

- Optional hopper for product storage.

- Optional screening to remove small undersize product.

- Static or mobile versions available.

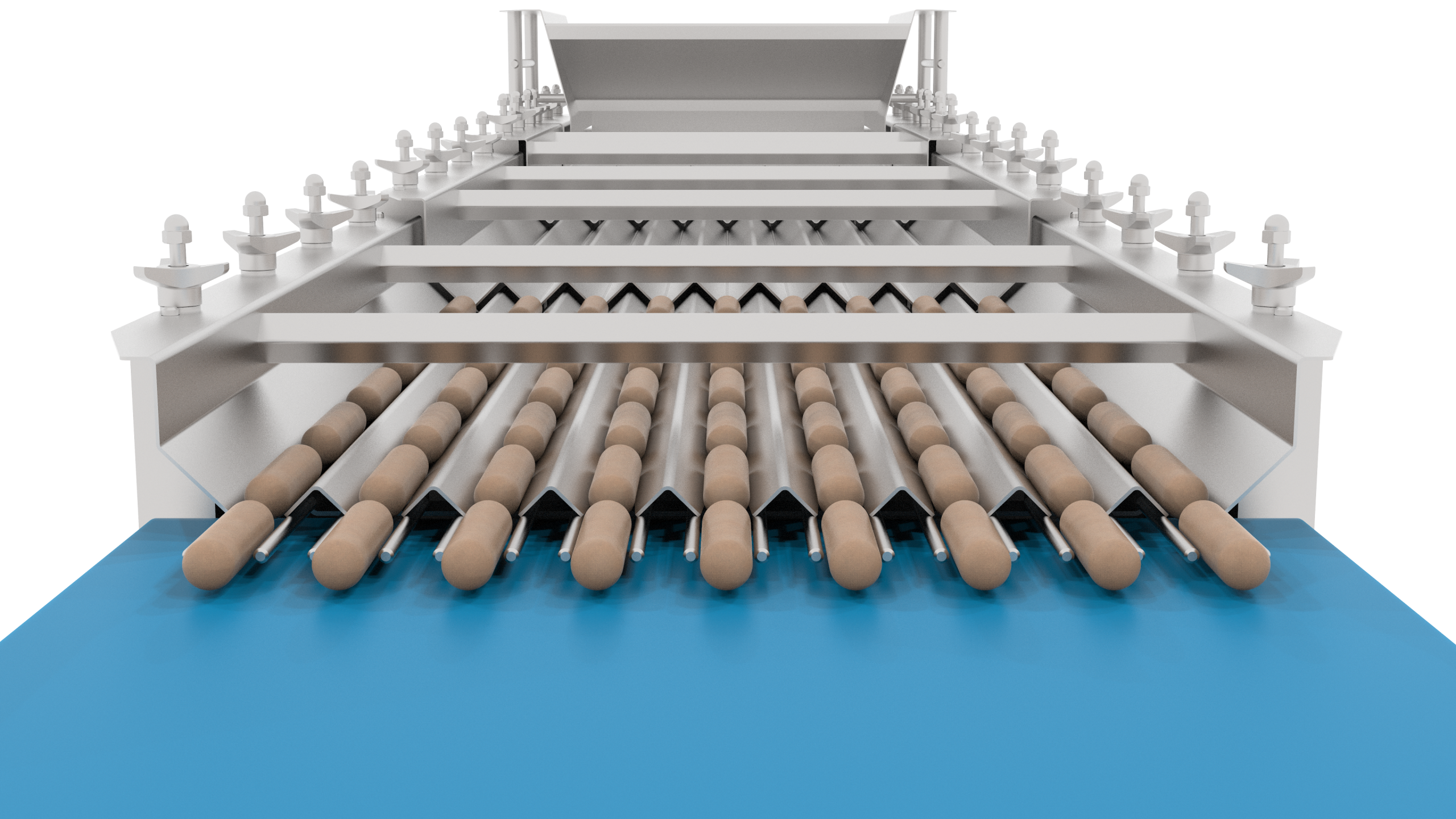

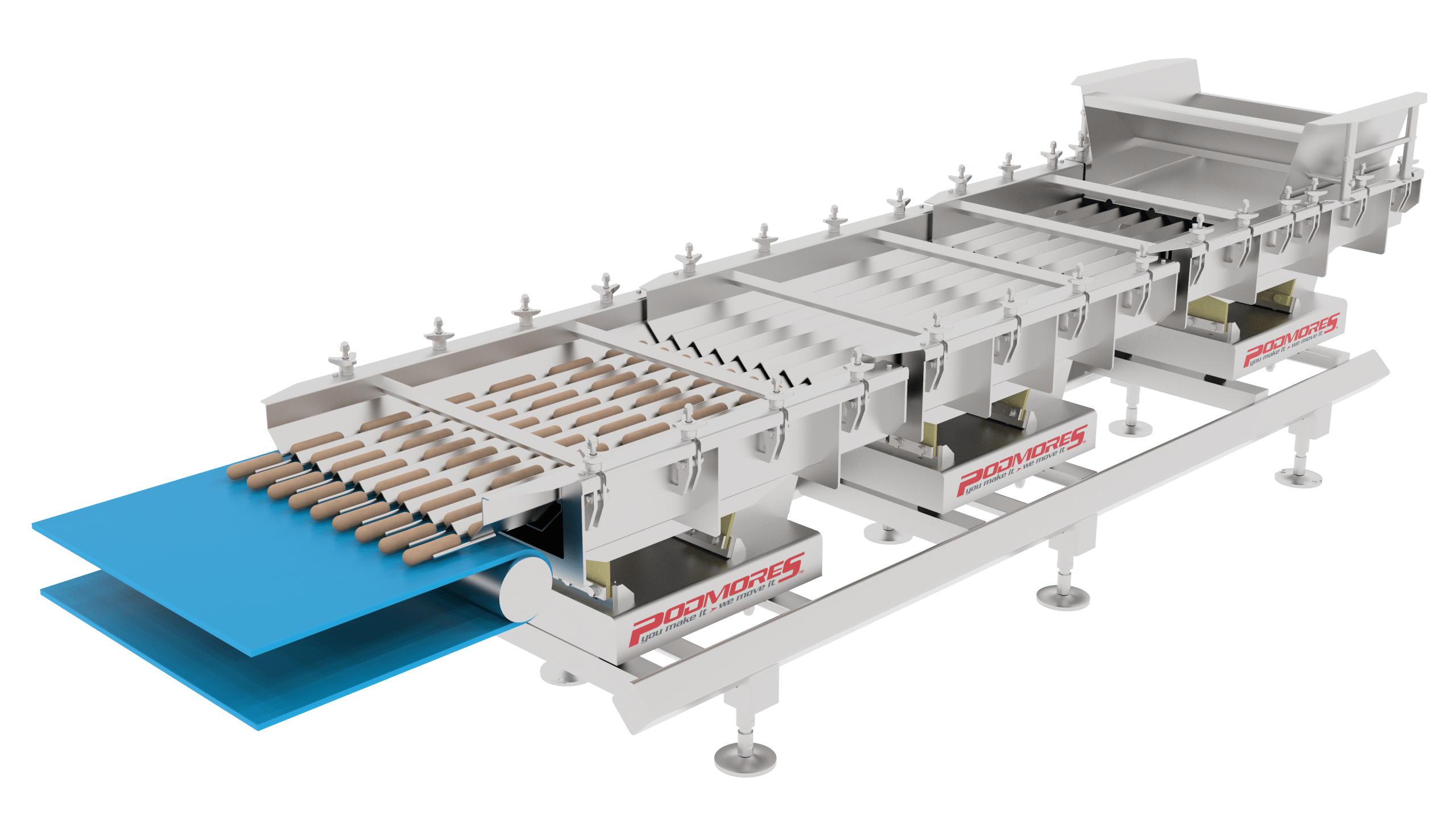

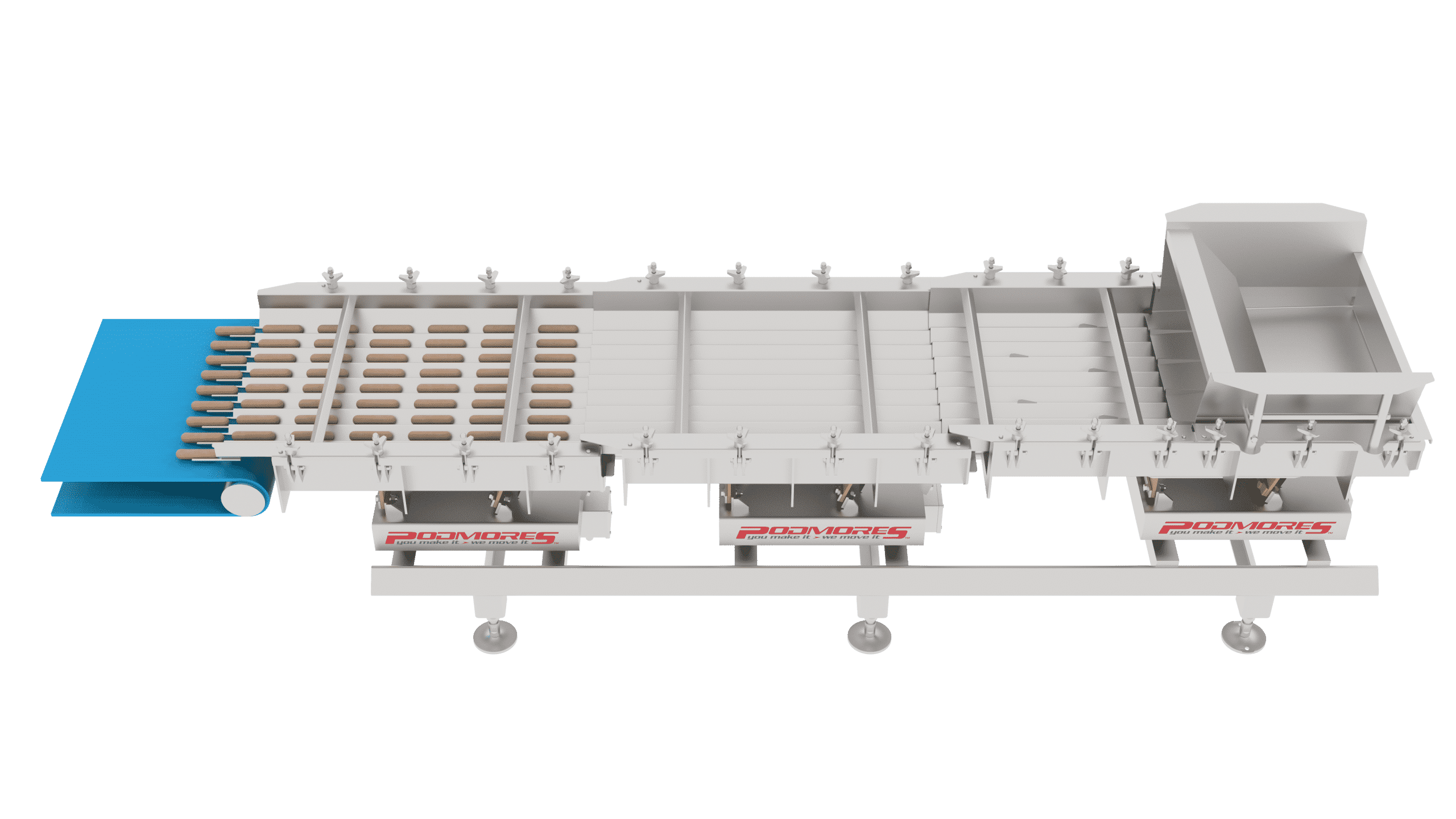

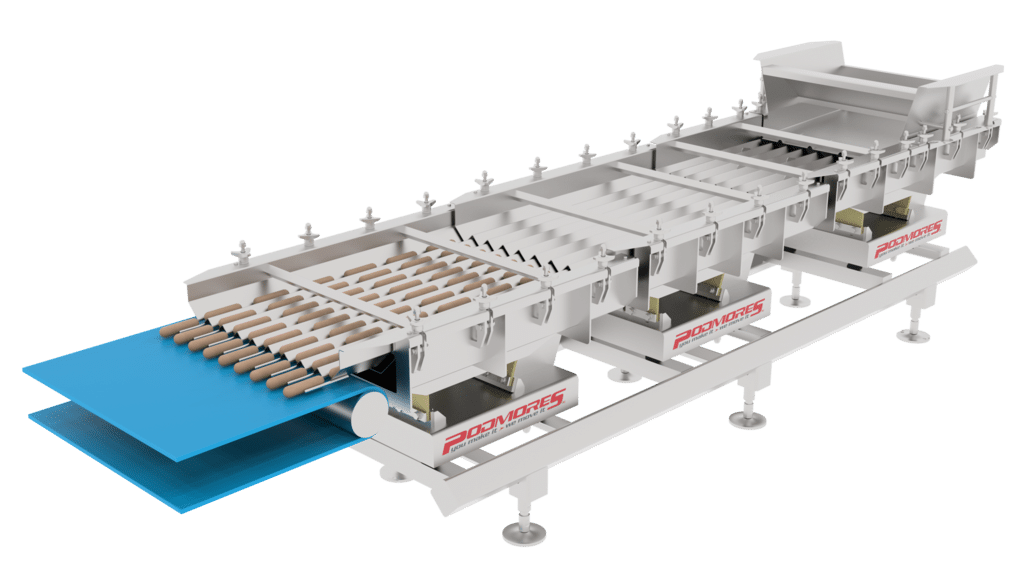

Hopper feeder to

store product,

freeing up

operators for

other tasks

Primary feeder to

spread product &

ensure an even feed

Secondary feeder

perfects the laning

of product

Tertiary feeder delivers

consistent lanes to

the downstream conveyor

Interchangeable lane

decks for quick

product format

changeover

Podmores' proven

vibratory drive

technology

Hygienic design for

the food and

pharmaceutical

industries

Proven Technology

Podmores Laning Feeders are found in factories all over the world, from small businesses to household name companies. Podmores Laning Feeders provide the nuts, chocolates and confectionary for enrobing, sausages, burgers, prawns and fish for robot picking and much more, and are trusted in critical production line processes. Their durable design means almost no downtime.

Optimised

Optimised laning of product before enrobing can reduce wastage by as much as 25% by spacing product effectively and reducing product passing under the enrober too closely together and fusing. Similarly, an efficient infeed for a robot pick & place application can be the critical process required to ensure your robots meet their required throughputs but always having a consistent delivery of pickable products.

Gentle

Podmores vibratory Laning Feeders offer an incredibly gentle solution to your products. Since 1930 we’ve handled almost every product imaginable, including products as gentle as chocolate curls/shavings and without damaging hard candy shells. This experience and our testing/demonstration facilities allow us to prove to you that our solutions are the best option for our orientation and sorting needs.

Fill and forget

Our expertise with Storage & Infeed Systems allows us to deliver a solution no matter how much product you want to hold and how little you want to have to top the system up. Podmores can help you deploy storage solutions that keep your operatives free for other tasks around your factory.

Want to find out more?

Controllers

Spacing

Output

Hygienic Design

ATEX

Related products

Get in touch

Contact Us

ADDRESS

Podmores (Engineers) Ltd

Unit H Great Fenton Business Park, Grove Road, Stoke, Staffordshire,

ST4 4LZ, UK

Solving automation problems since 1930