Concept, design & manufacture of bespoke automated systems for your process needs. Bringing industrial automation to everyone.

Share

Learn more

Videos

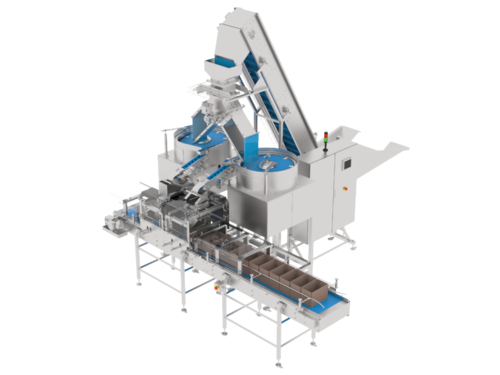

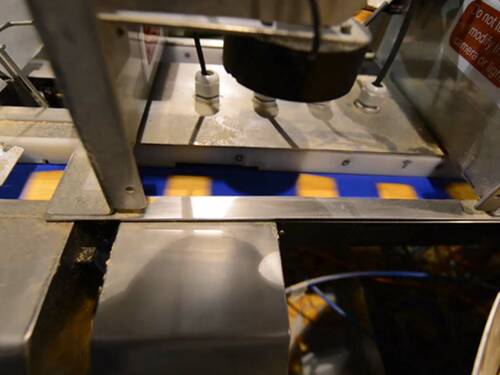

Sprinkling, Spreading & Depositing

Automating your production processes

Bespoke industrial automation solutions.

Identify

Podmores work with you to identify the best solution for you now and in the future.

Design & Concept

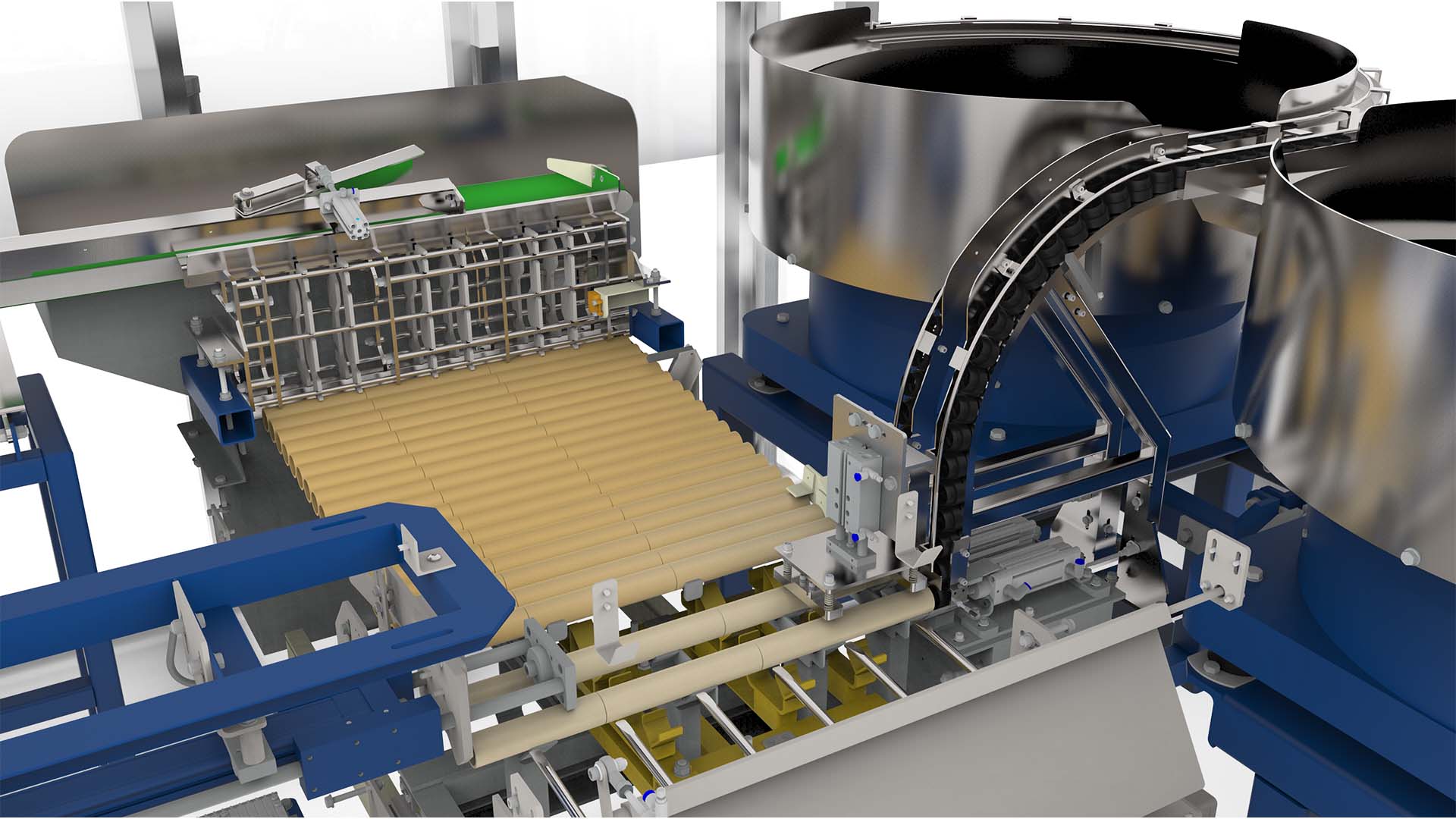

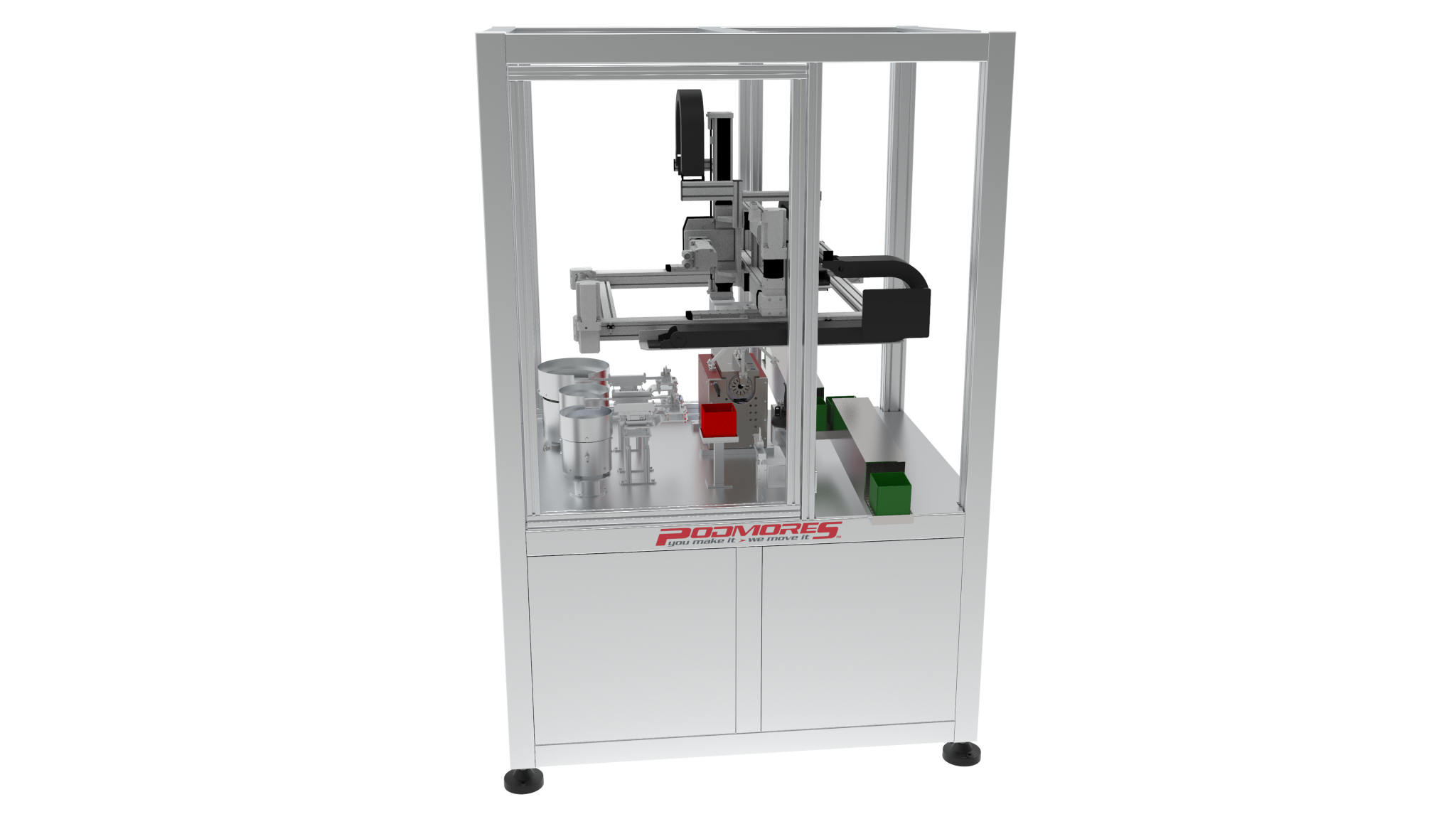

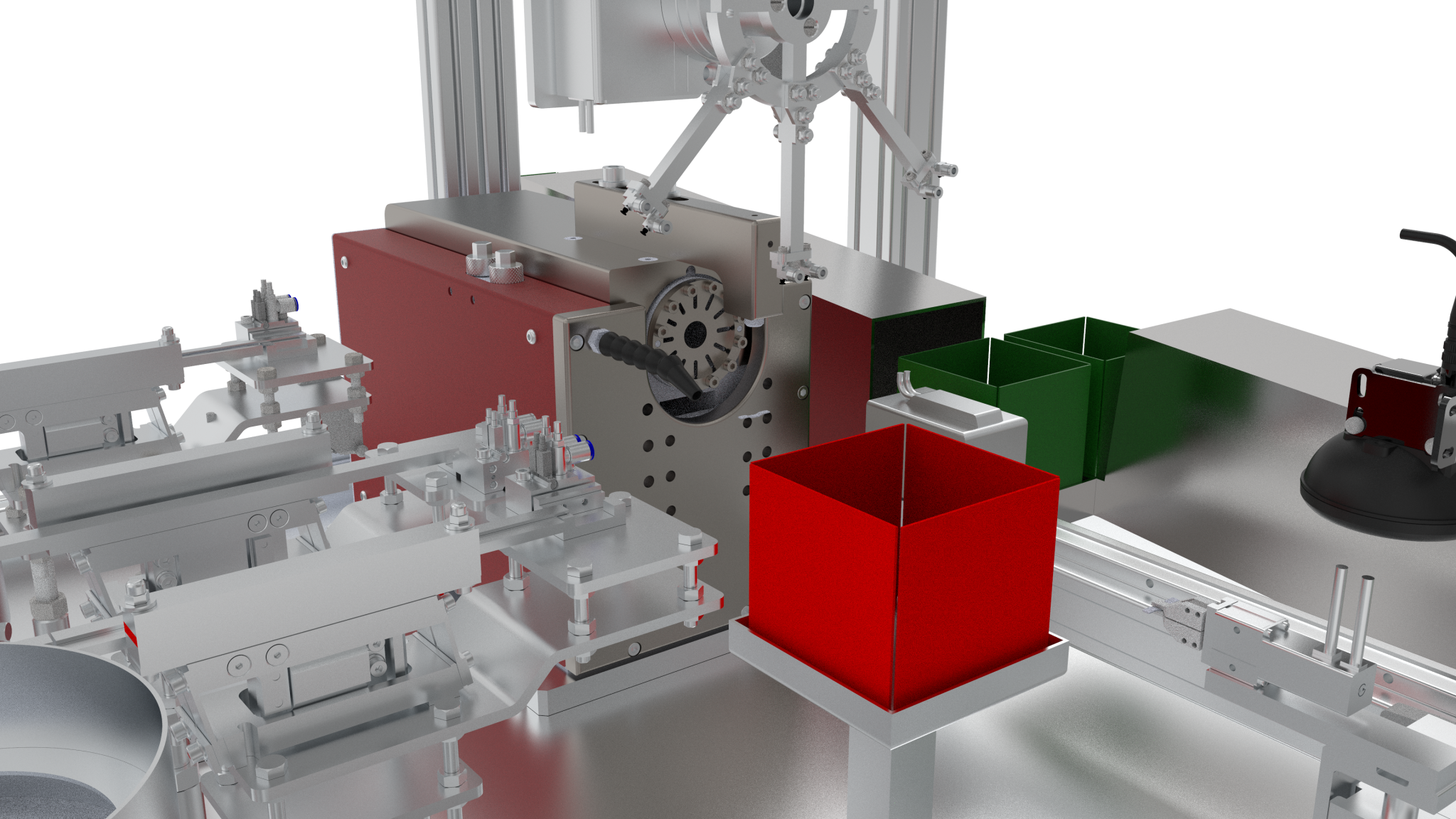

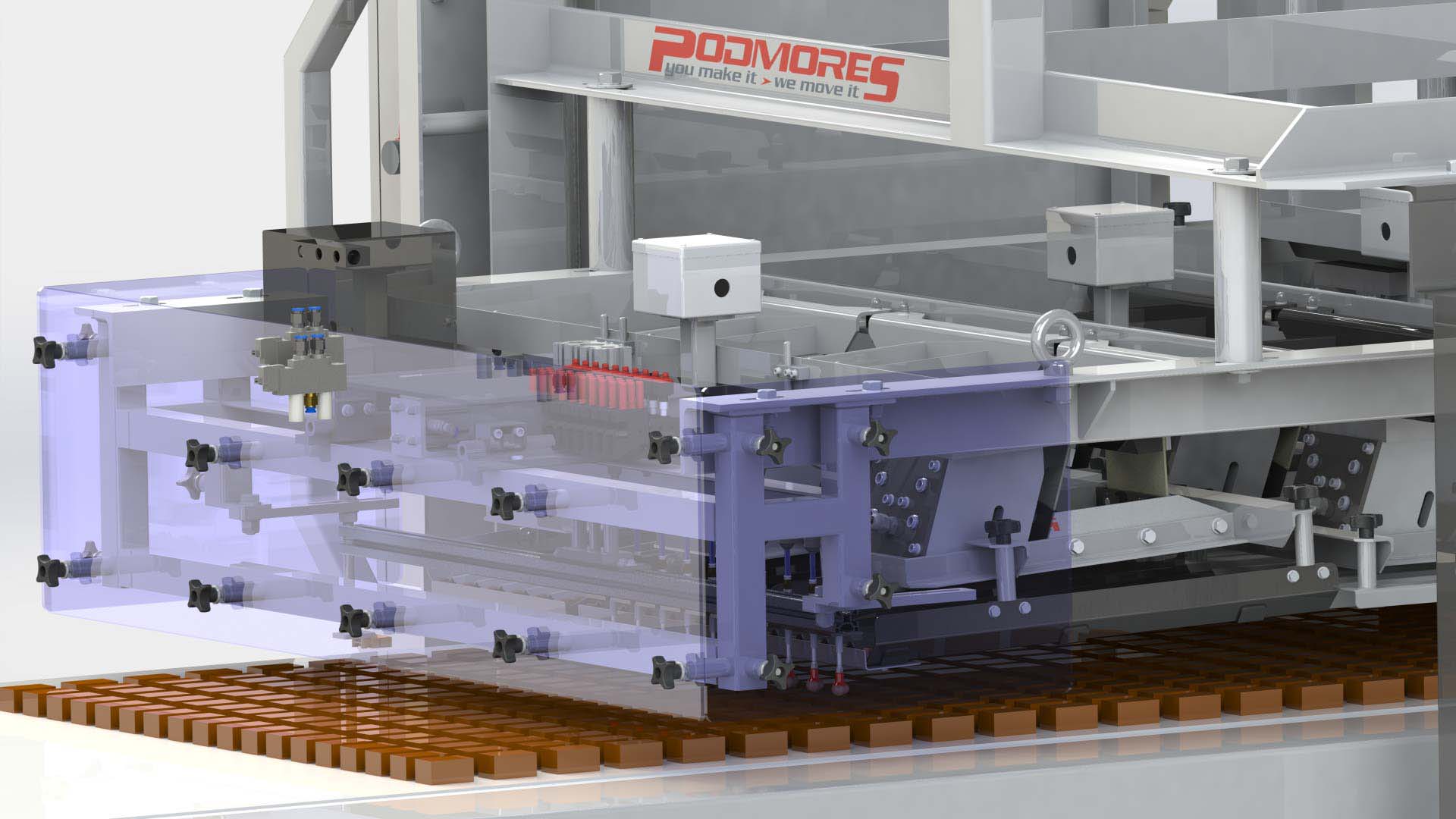

We design the system using the latest 3D CAD software so that it can be virtually reviewed prior to manufacture.

Safety

We ensure the system complies with all relevant safety standards.

Reliable

Podmores offer an industry leading reliable design proven for 24/7/365 operation in critical process conditions.

Low Noise Level

Where noise may be a consideration we can assist with identifying ways of reducing it.

Low Running Cost

We explore options to keep running costs down.

Easy to clean

We're used to our machinery going into all sorts of environments and can ensure that it's designed for ease of cleaning.

Customised Solution

Podmores offer a customised solution to your industrial automation needs.

Want to find out more?

Applications

- Almost any component/product

- And more

Key benefits

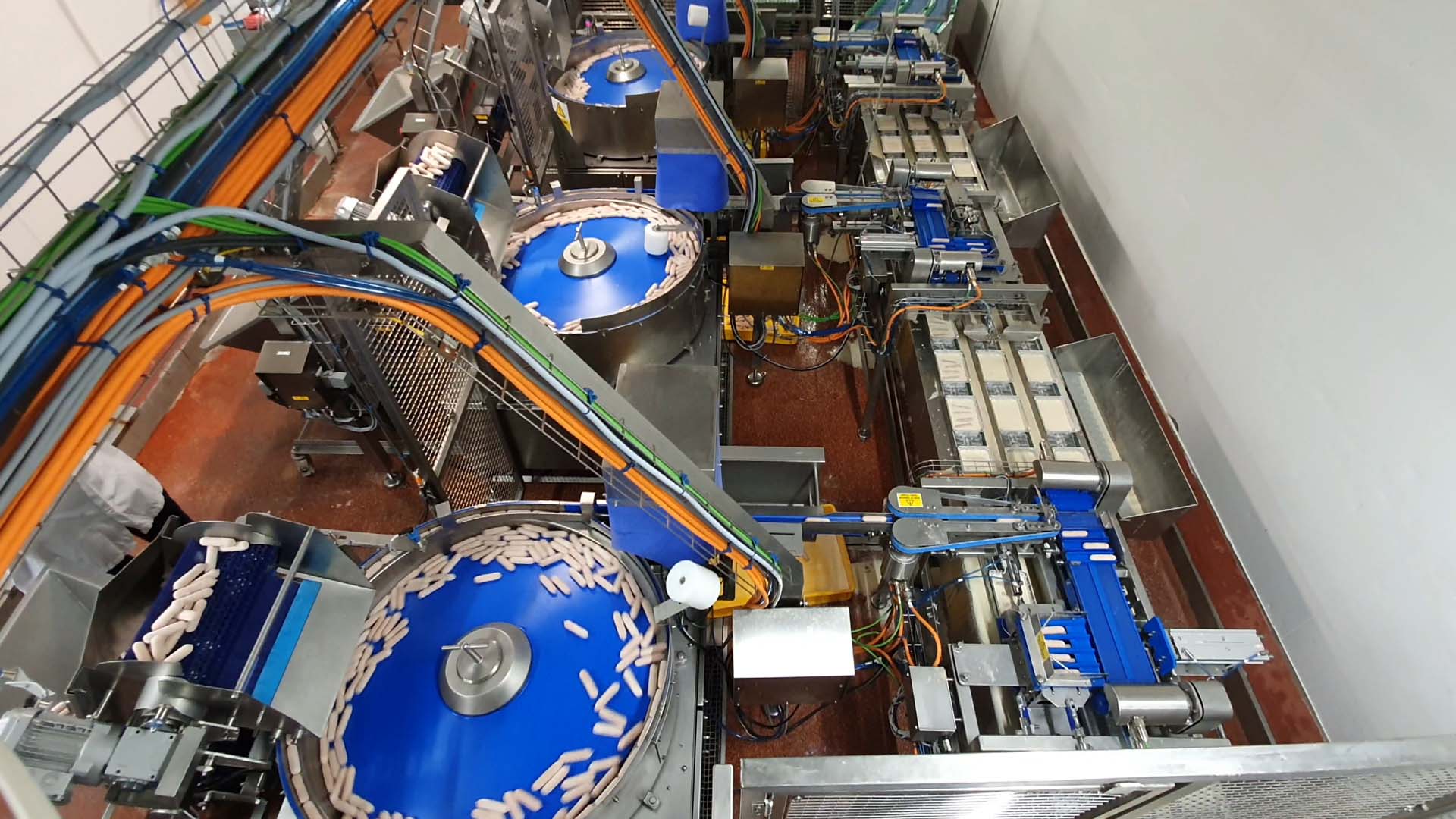

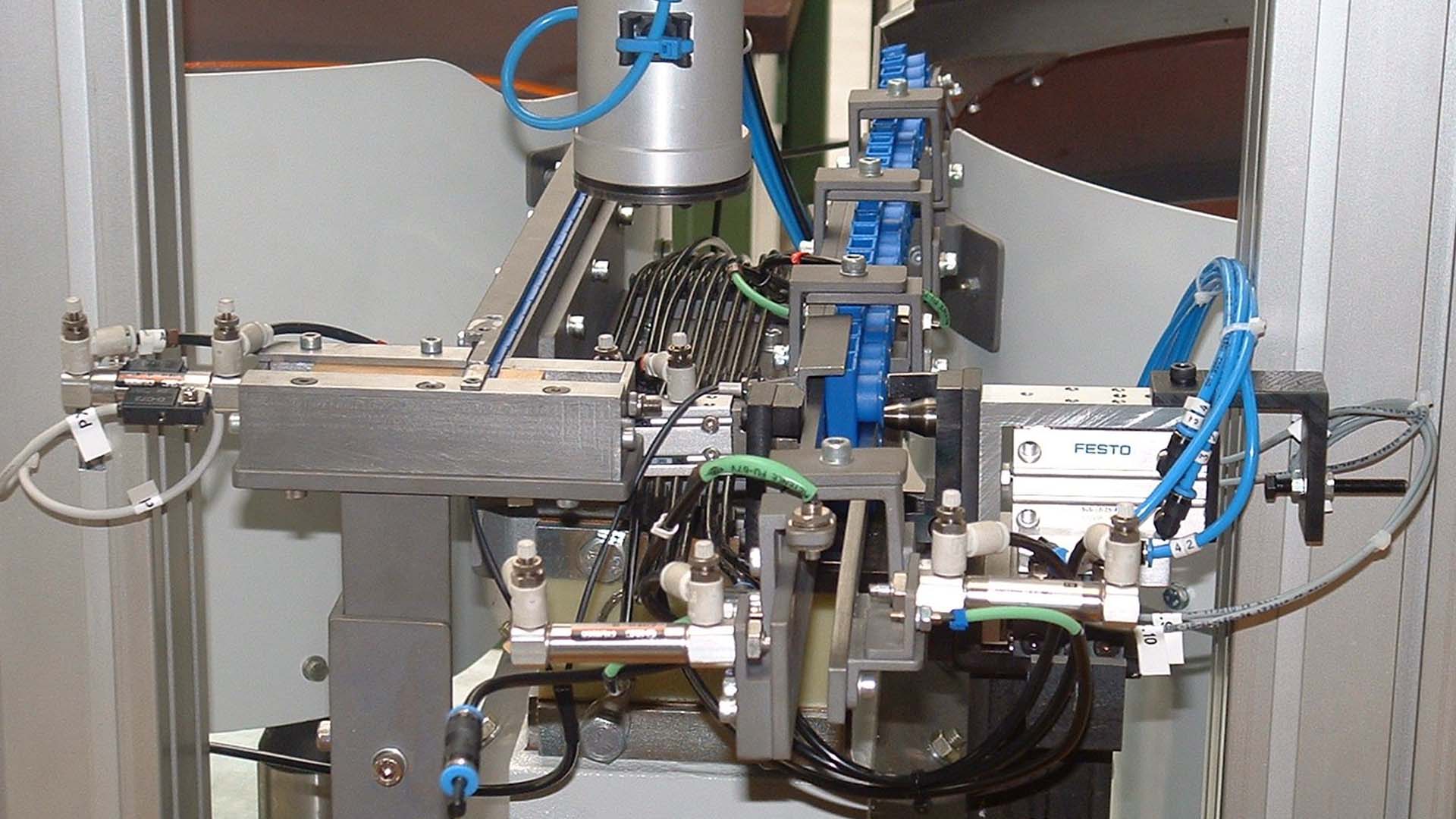

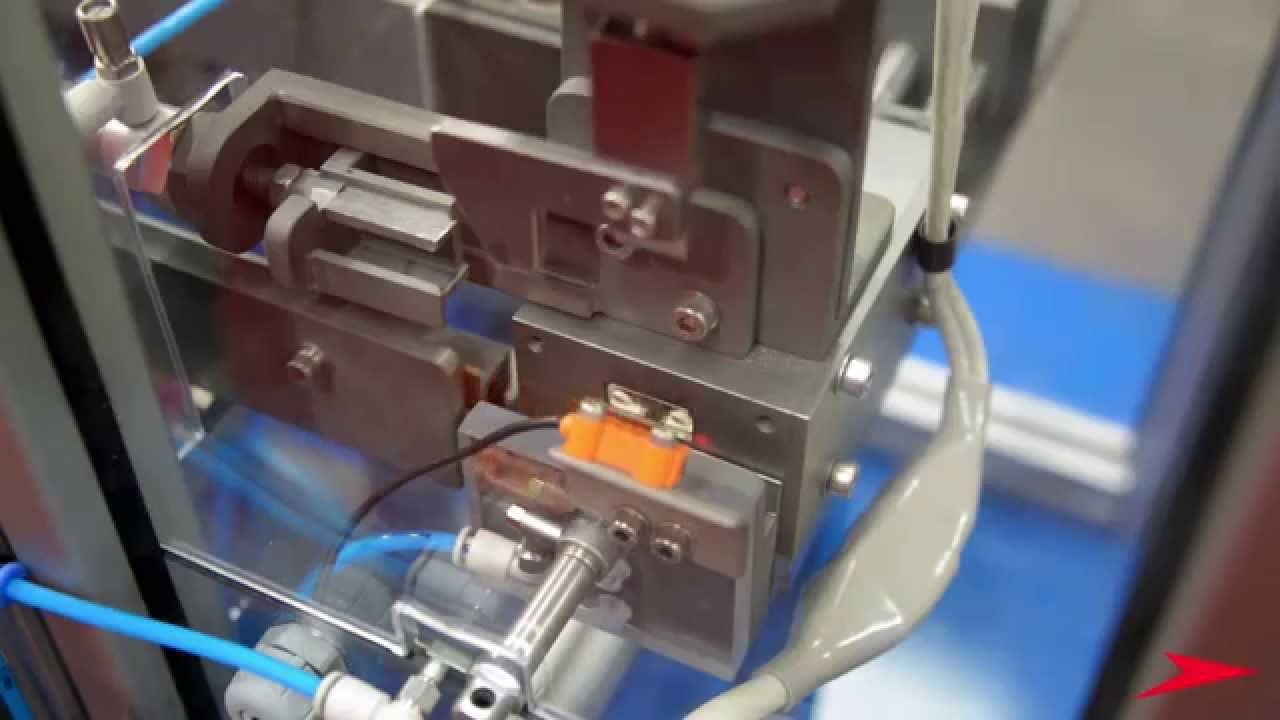

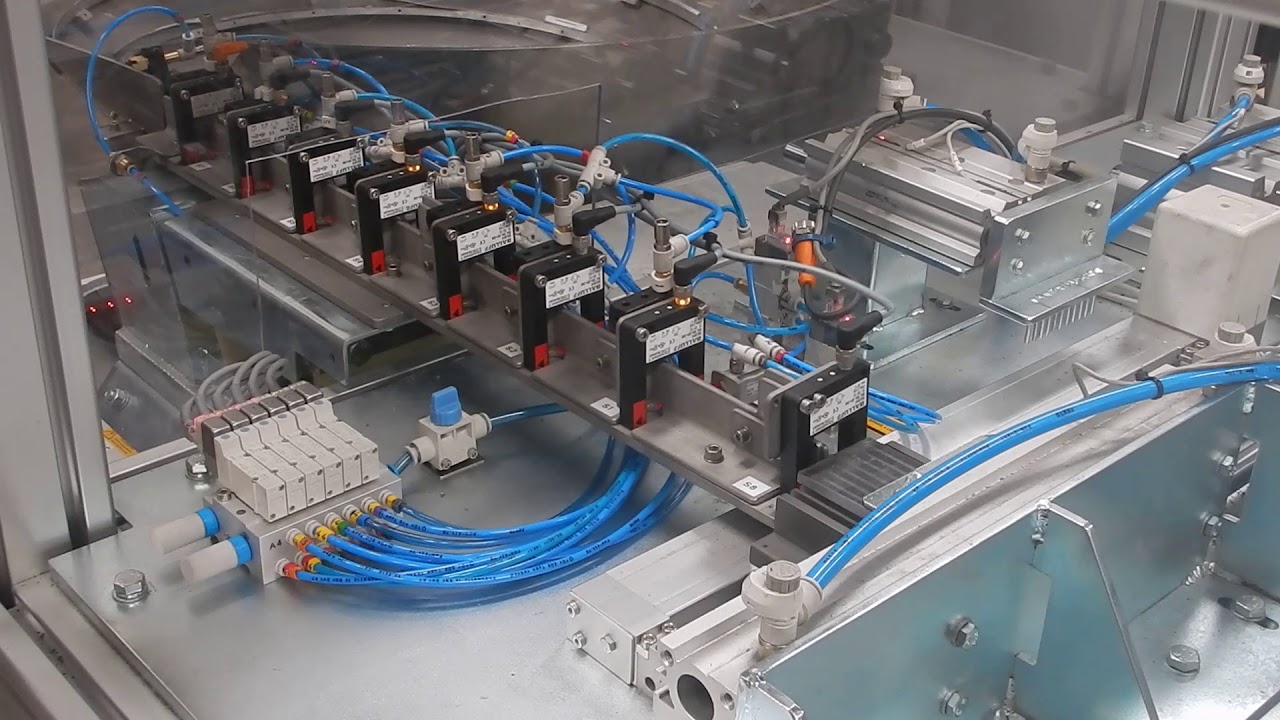

Podmores has decades of experience in the design and manufacture of a wide range of automated assembly systems as well as a range of assembly and testing solutions in a wide range of industry sectors. We are a turnkey solutions provider, offering full scoping, design, manufacture and installation of bespoke industrial automation systems. Our systems can help you improve your production throughput rates as well as improving quality, ultimately boosting your overall equipment effectiveness (OEE).

Podmores’ automated systems can help you either keep production onshore, or bring back production from oversees to provide localised manufacturing capabilities using the latest technologies. Typically our customer can realise a return on investment (ROI) between 6 to 24 months making it easy to deploy automated solutions within your short to medium term strategic plans.

From simple poka-yoke automation systems to fully automated robotic assisted assembly lines, Podmores can offer a solution to meet your requirements, working with you to develop a bespoke solution.

Podmores have experience in a wide range of solutions from simple two part assembly machines to fully automated packaging solutions in almost every industry.

- Custom built to your specific requirements.

- Short Payback & Impressive ROI.

- Hygienic/washdown configurations available.

- Flexible Fast & Simple Change Over.

- Built-in vision inspection quality control available.

- Reduce defects.

Safety interlocked

doors

A range of robotic

automation solutions

available

Vision inspection

for quality control

Fully operated and

controlled via a

touchscreen HMI

Proven Technology

Podmores have a wealth of experience designing and manufacturing automated solutions for a wide range of industries, including food, pharmaceutical, FMCG and automotive.

We utilise a range of new technologies, combined with our 90 years of experience, to deliver a robust automated solution that works specifically for your needs.

Optimised

Typically robotic automated systems are heavily reliant on their infeed system. Podmores’ experience in materials handling and product sorting makes us an excellent choice for automation because we have an industry leading knowledge base of parts handling.

Gentle

Podmores experience in handing almost every part imaginable over the years allow us to rapidly develop a bespoke solution to even the most fragile of parts automation projects.

Fill and forget

Our expertise with Storage & Infeed Systems allows us to deliver a solution no matter how much product you want to hold and how little you want to have to top the system up. Podmores can help you deploy storage solutions that keep your operatives free for other tasks around your factory.

Want to find out more?

Controllers

Spacing

Output

Hygienic Design

ATEX

Get in touch

Contact Us

ADDRESS

Podmores (Engineers) Ltd

Unit H Great Fenton Business Park, Grove Road, Stoke, Staffordshire,

ST4 4LZ, UK

Solving automation problems since 1930