Podmores Infeed Hoppers allow you to fill up one hopper with your product and let it feed other machines at the rate you require. No longer will you have to hand fill machines throughout the day, load our Hoppers up and leave them to empty.

| Frequency | 50Hz, 60Hz |

|---|---|

| IP Rating | IP54, IP65, IP66, IP67, IP68 |

| Materials | Aluminium, FDA Approved Plastics, FDA Rubber Lined, Mild Steel, Plastics, Rubber Lined, SS304, SS316L |

| Voltage | 110V, 230V, 415V |

Share

Learn more

Videos

Sprinkling, Spreading & Depositing

Automatic top up, freeing operators and ensuring performance

Let your system automatically control its own fill level with an Infeed Hopper.

Hold product

Create a buffer of product by allowing operators to load the Infeed Hopper and move on to other tasks.

Automatic operation

The Infeed Hopper will turn on as required, controlled by the next machine.

Call for help

The Infeed Hopper will call an operator to reload it with plenty of time to spare, ensuring no loss in performance of the system.

Reliable

Podmores offer an industry leading reliable design proven for 24/7/365 operation in critical process conditions.

Low Noise Level

The emission sound pressure level of our Infeed Hoppers is below 70 dB(A) at 1m distance, without product (Lpa re. 20µPa).

Low Running Cost

A basic Infeed Hopper costs as little as £0.05 per hour in operation.

Easy to clean

No moving parts and our hygienic design mean an easy to clean machine suitable for raw food contact.

Customised Solution

Podmores offer a customised solution to your materials handling needs.

Want to find out more?

Applications

- Almost any component/product

- Dry, flowable ingredients

- Cereal

- Chocolate

- Cheese (including grated)

- Chewing gum

- Coffee

- Confectionary

- Fish

- Fruit

- Grains

- Inclusions & toppings

- Meat

- Nuts

- Pasta

- Pharmaceuticals

- Popcorn

- Powders

- Rice

- Seafood

- Seeds

- Snack Foods

- Tea

- Vegetables

- And more

Key benefits

Podmores Infeed Hoppers allow you to fill up one hopper with your product and let it feed other machines at the rate you require. No longer will you have to hand fill machines throughout the day, load our Hoppers up and leave them to empty.

Our Infeed Hoppers communicate with other machinery to supply the right rate and stop if no product is required. This ensures optimum performance throughout your factory. When the Hopper is running low it will alert you so you never run short.

- Vary speeds easily and simply.

- Creates even and consistent delivery of product.

- Constant feed rate that doesn't adjust over time.

- Compact design fits into existing production lines or new lines easily.

- Hygienic design and stainless steel contact materials.

- Static or mobile versions available.

- No moving parts.

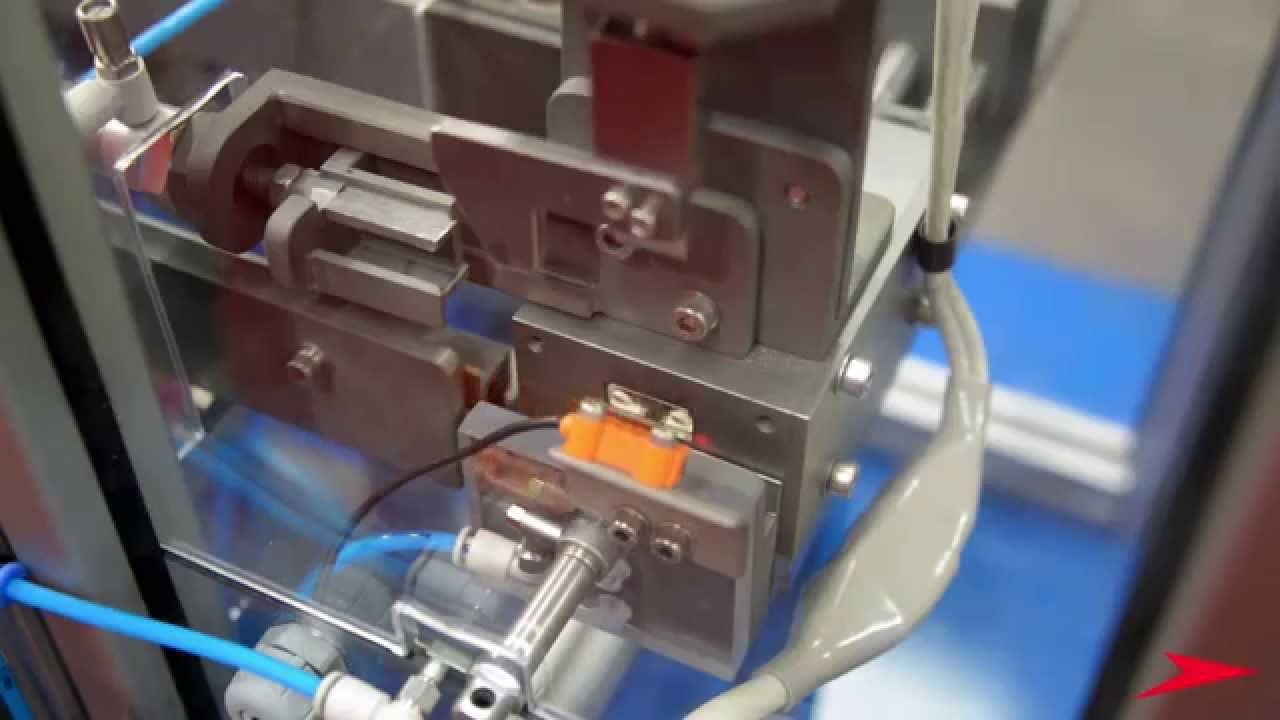

Adjustable gate

to set the layer

depth of product

Optional cutouts

to suit manual

loading while

keeping heights

low

A range of end

options to suit

feeding machines

straight on or

from an angle

Proven Technology

Podmores Infeed Hoppers are found in factories all over the world, from small businesses to household name companies. Podmores Infeed Hoppers provide almost every product imaginable, from chocolates and confectionary, to fruit, nuts and popped popcorn. In non food applications they are used for fasteners, plastic parts, bottles, caps and much more, and are trusted in critical production line processes. Their durable design means almost no downtime.

Reliable

Our Infeed Hoppers are trusted in 24/7 operations in the largest companies in the world. We regularly come across machinery that has been running without interruption for 40+ years and that’s still going as well as it was when we originally sold it.

Tough but gentle

Podmores Infeed Hoppers are incredibly tough, handling product as hard as diamonds and aggregate, through to popped popcorn. Since 1930 we’ve handled almost every product imaginable, including products as gentle as chocolate curls/shavings and without damaging hard candy shells. This experience and our testing/demonstration facilities allow us to prove to you that our solutions are the best option for our orientation and sorting needs.

Want to find out more?

Controllers

Hygienic Design

ATEX

Related products

Get in touch

Contact Us

ADDRESS

Podmores (Engineers) Ltd

Unit H Great Fenton Business Park, Grove Road, Stoke, Staffordshire,

ST4 4LZ, UK

Solving automation problems since 1930