Gently elevate and/or conveyor your product with the Simatek® Bucket Elevator.

| Frequency | 50Hz, 60Hz |

|---|---|

| IP Rating | IP54, IP65, IP66, IP67, IP68 |

| Materials | FDA Approved Plastics, Mild Steel, Plastics, SS304, SS316L |

| Voltage | 110V, 230V, 415V |

Share

Learn more

UK agents

Videos

Bucket Elevators

Gentle elevation

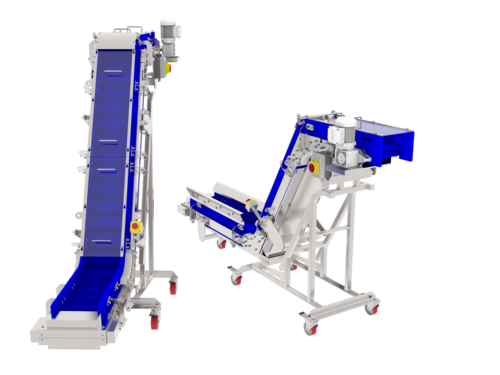

The smoothest, gentlest elevation method for the most demanding, and/or space limited applications.

Space Saving

The compact design of a Bucket Elevator suits compact factory layouts or busy production areas.

Elevation

Vertical and horizontal transfer of your product.

Modular

Easily configurable design to exactly suit your requirements, including multiple inlet and outlet points.

Gentle handling

Bucket Elevators provide one of the most gentle methods of elevating product.

Low Noise Level

The emission sound pressure level of a standard Bucket Elevator is below 65 dB(A) at 1m distance, without product (Lpa re. 20µPa).

Low Running Cost

A basic Bucket Elevator costs as little as £0.09 per hour in operation.

Variable throughput

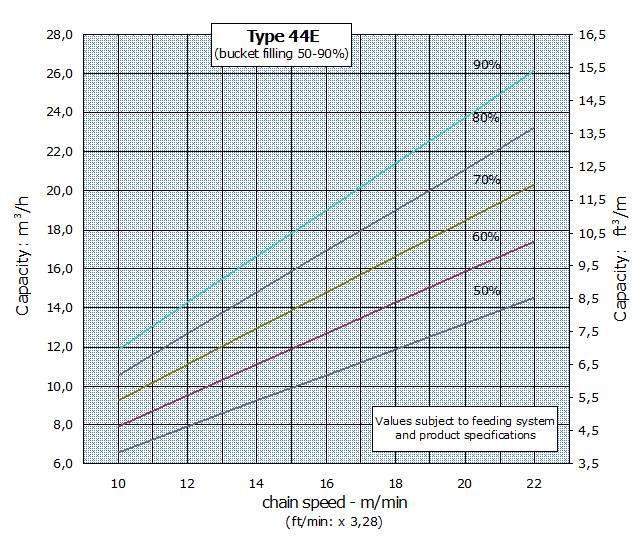

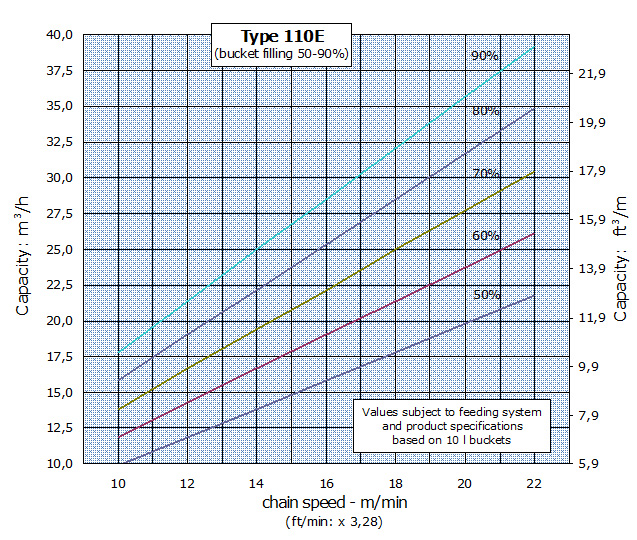

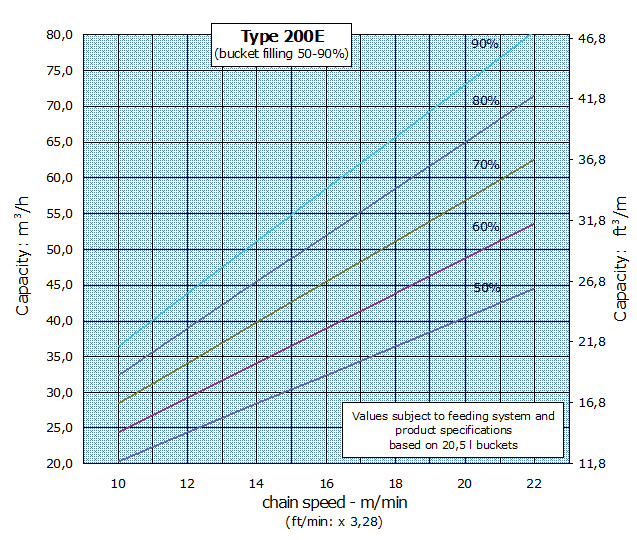

Different bucket sizes and variable speeds allow varying levels of throughput to suit your needs.

Customised Solution

Podmores offer a customised solution to your materials handling needs.

Want to find out more?

Applications

- Almost any component/product

- Aqua feed

- Catalysts

- Cocoa powder

- Coffee

- Detergents

- Enzyme powder

- Fertiliser

- Flour

- Fly ash

- Grass seeds

- Limestone powder

- Maize

- Metal oxide

- Milk powder

- Minerals

- Oil seeds

- PVC powder

- Pet food

- Pharmaceuticals

- Pigments

- Potato starch

- Premix

- Protein powder

- Pumpkin seeds

- Rape seeds

- Salt

- Snack foods (including extruded)

- Soybeans

- Spice seeds

- Spices

- Sugar

- Sunflower seeds

- Tablets

- Tea

- Wood pellets

- And more

Key benefits

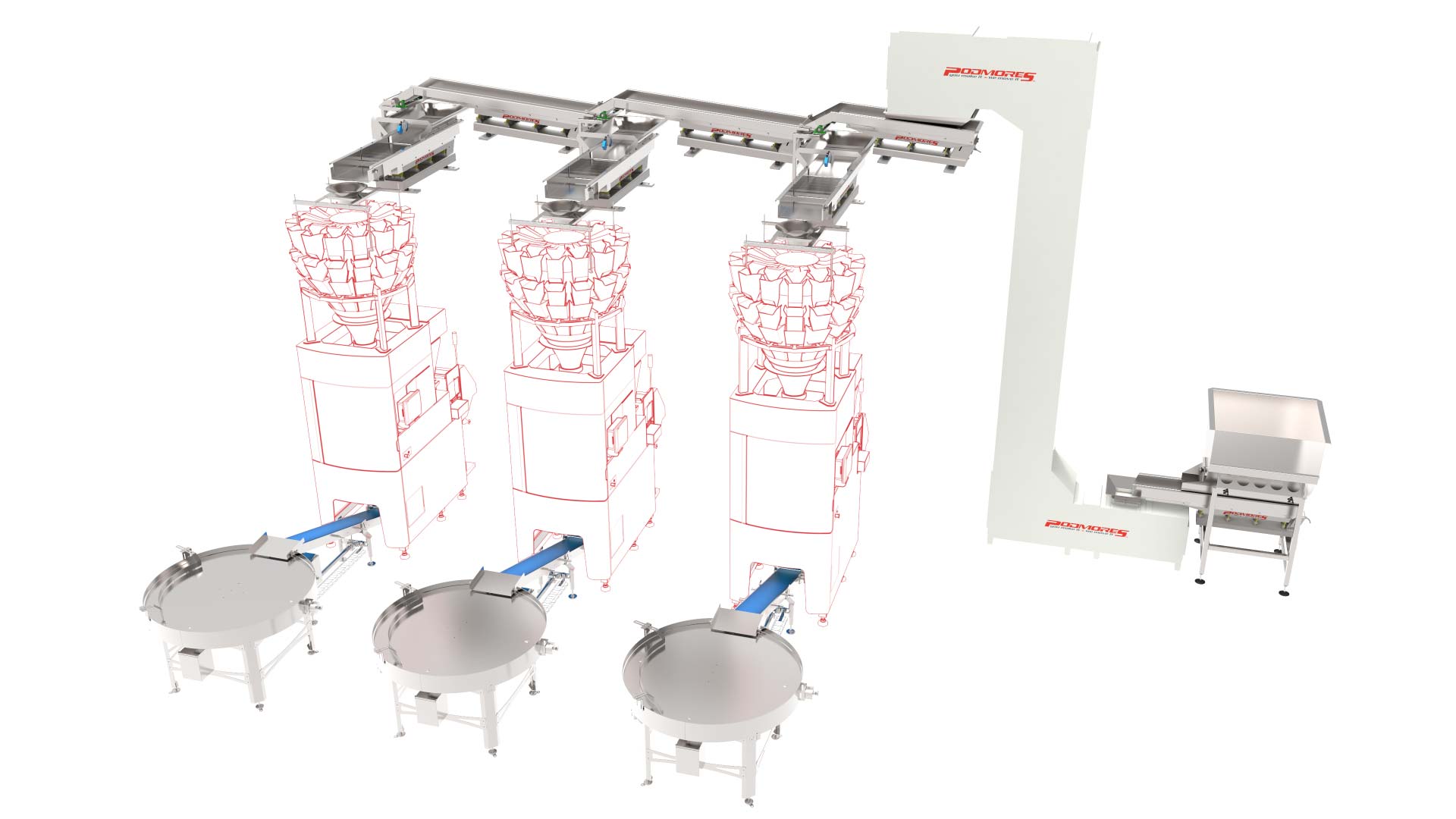

Podmores are the UK agent for Simatek® bucket elevators, providing flexible and space-saving conveying system designed for combined horizontal and vertical conveying of bulk products within the food processing, pet food, recycling and chemical industry, to mention but a few.

What makes Simatek® bucket elevators unique compared to other conveying systems is the way in which they carefully convey products without bringing about mechanical strain. The products thus remain in the same bucket from inlet to outlet with no damage.

- Gently convey your product without damage

- Compact footprint for space saving benefits

- Suitable for abrasive products

- Flexible and modular system

- Energy saving compared to chain/screws/others

- Easy to clean (self-cleaners available)

- Simple maintenance

Intermediate outlets

for multiple or

optional discharge

points

Standard discharge

point is at the

drive end

Vertical, horizontal

and corner modules

available

Service access

though low

level panels

Fill here

Corner and 'T'

shaped connectors

available

Proven Technology

Podmores Laning Feeders are found in factories all over the world, from small businesses to household name companies. Podmores Laning Feeders provide the nuts, chocolates and confectionary for enrobing, sausages, burgers, prawns and fish for robot picking and much more, and are trusted in critical production line processes. Their durable design means almost no downtime.

Modular Design

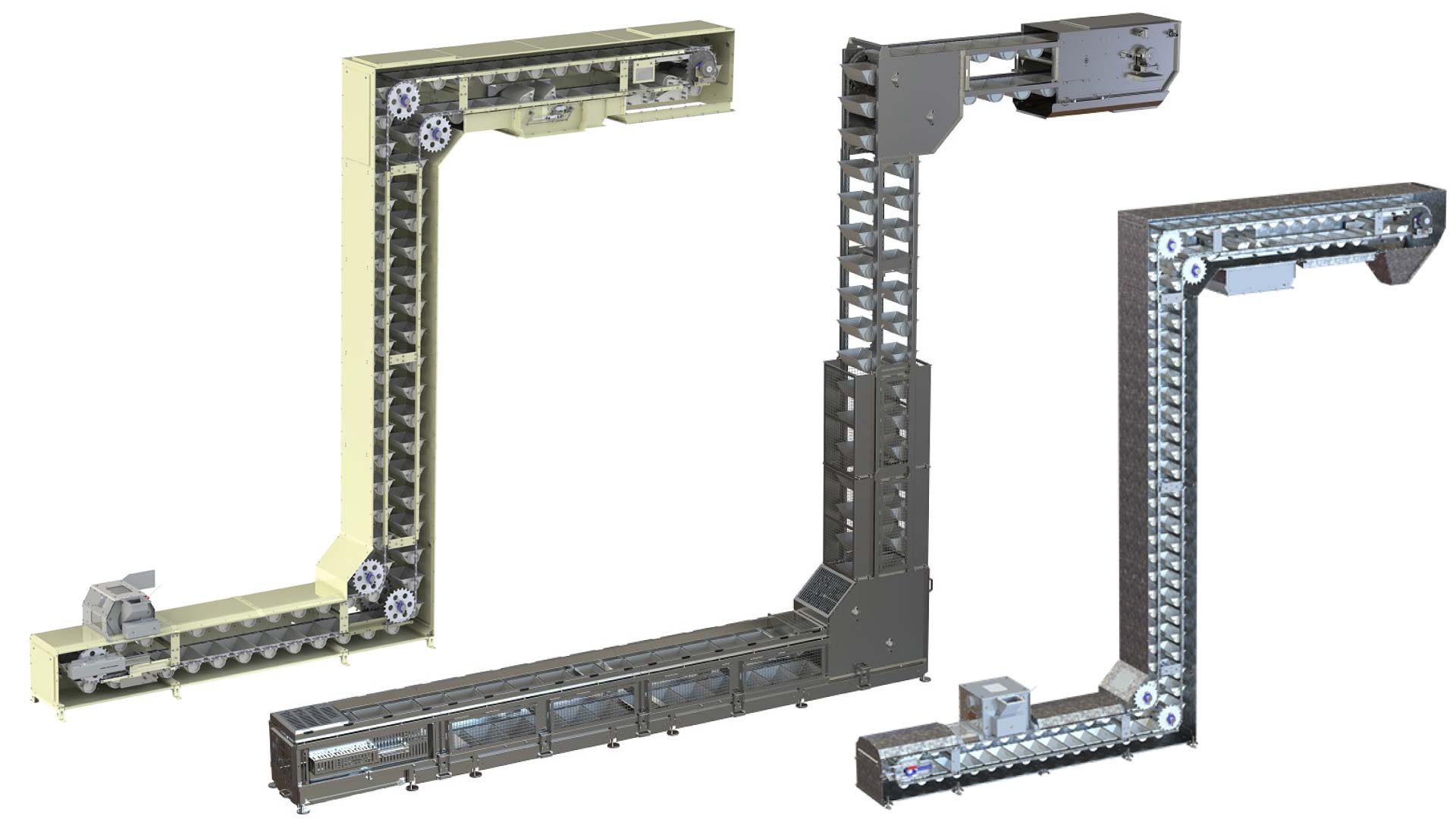

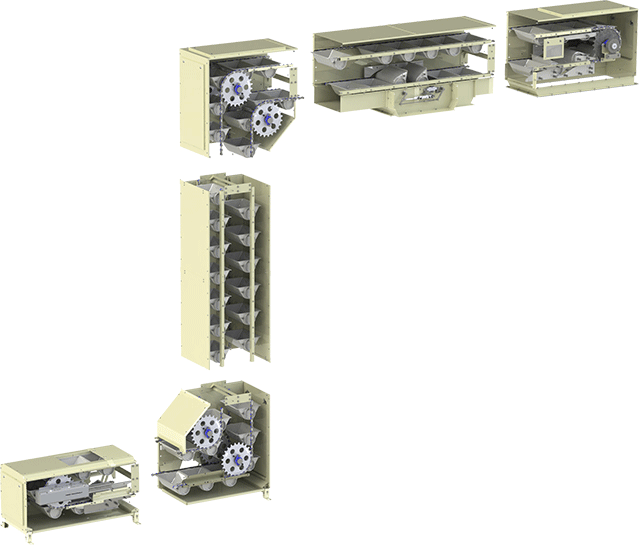

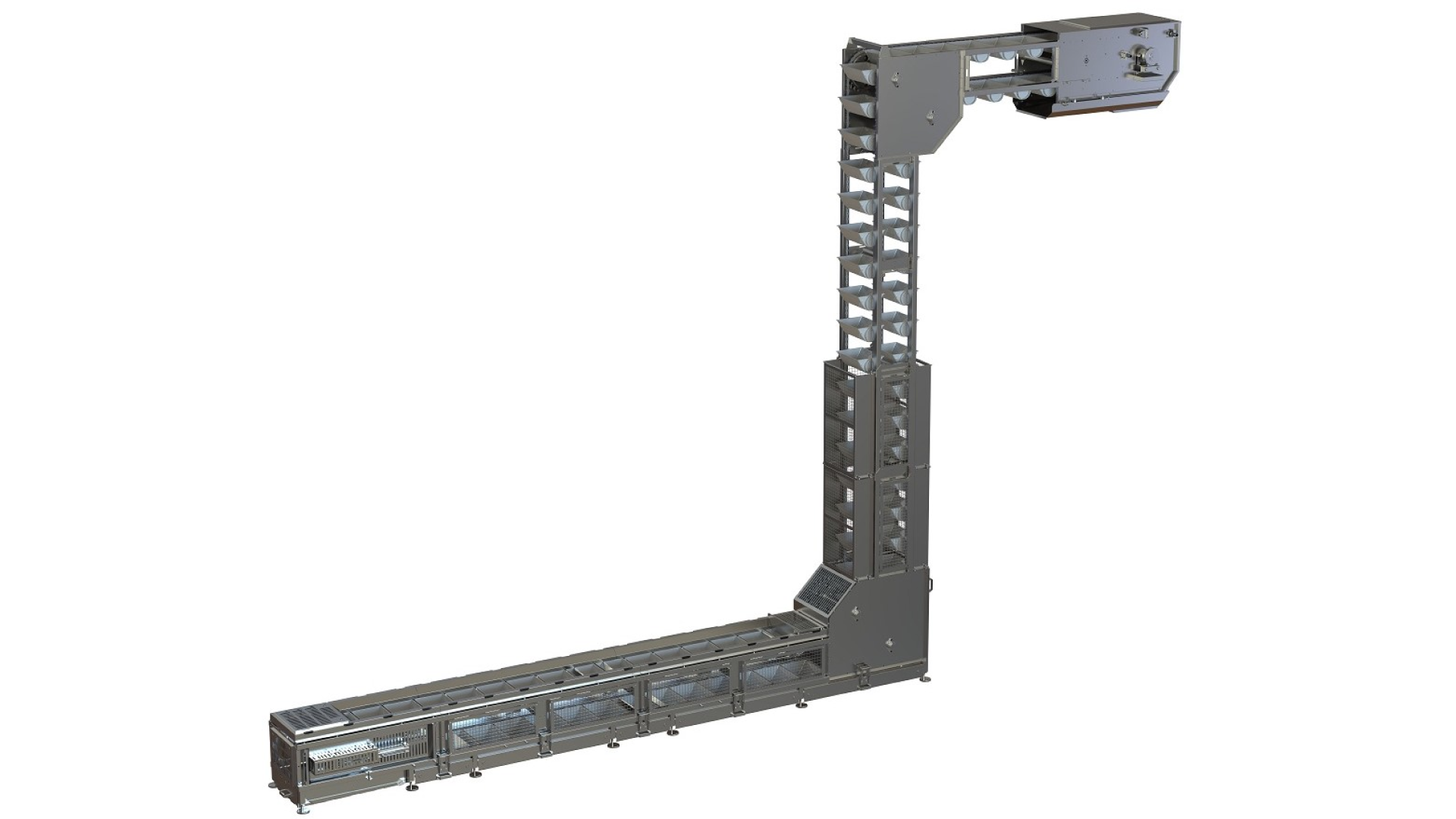

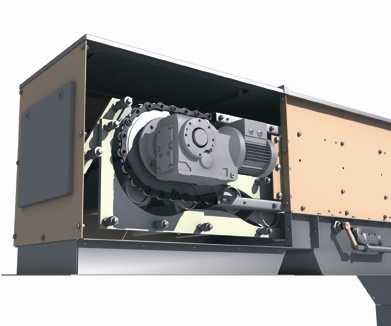

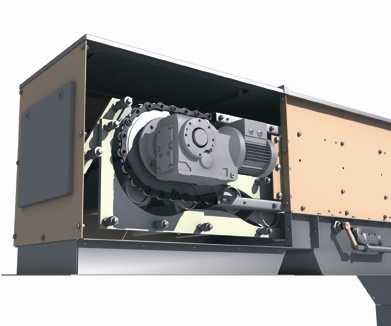

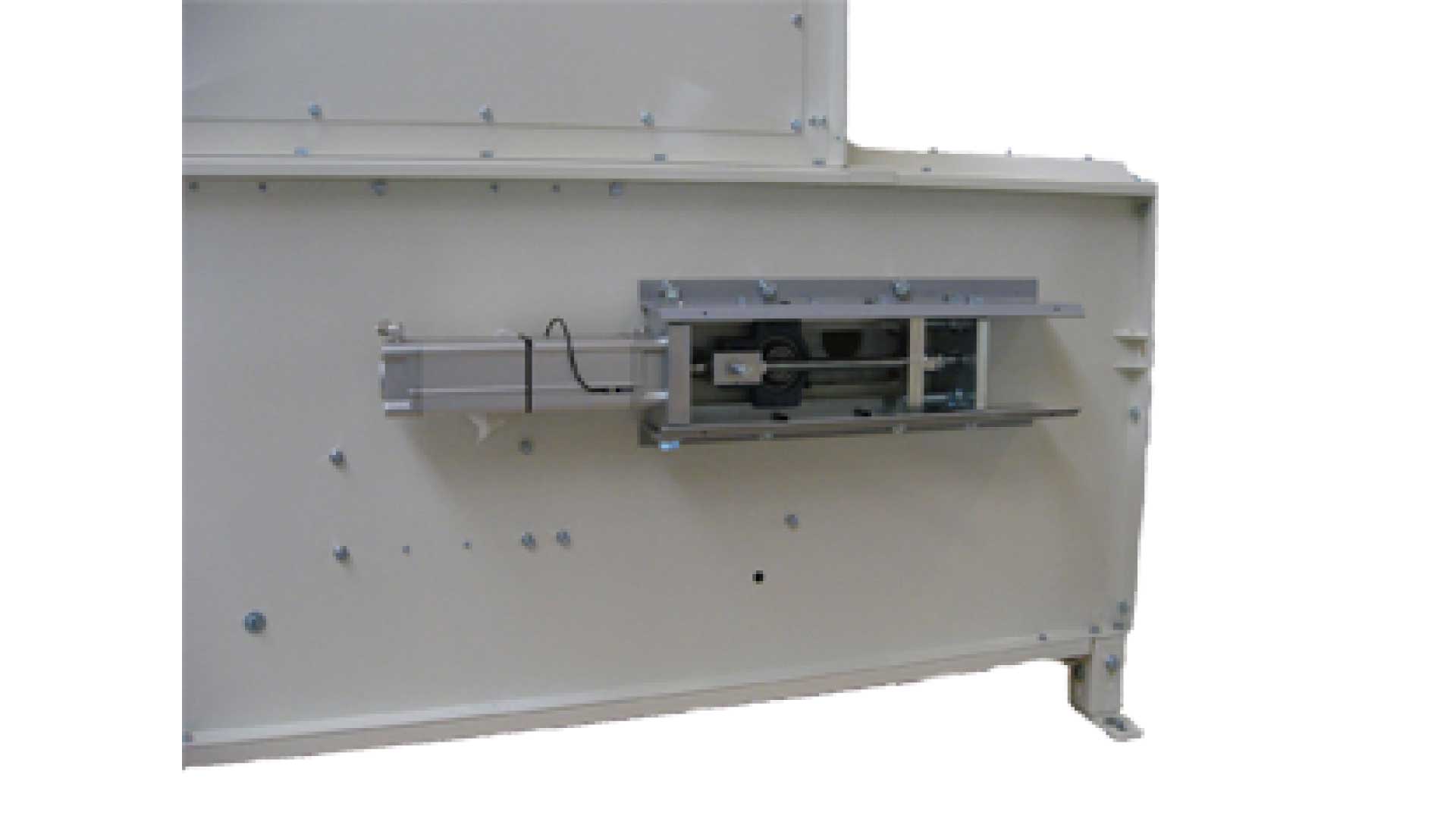

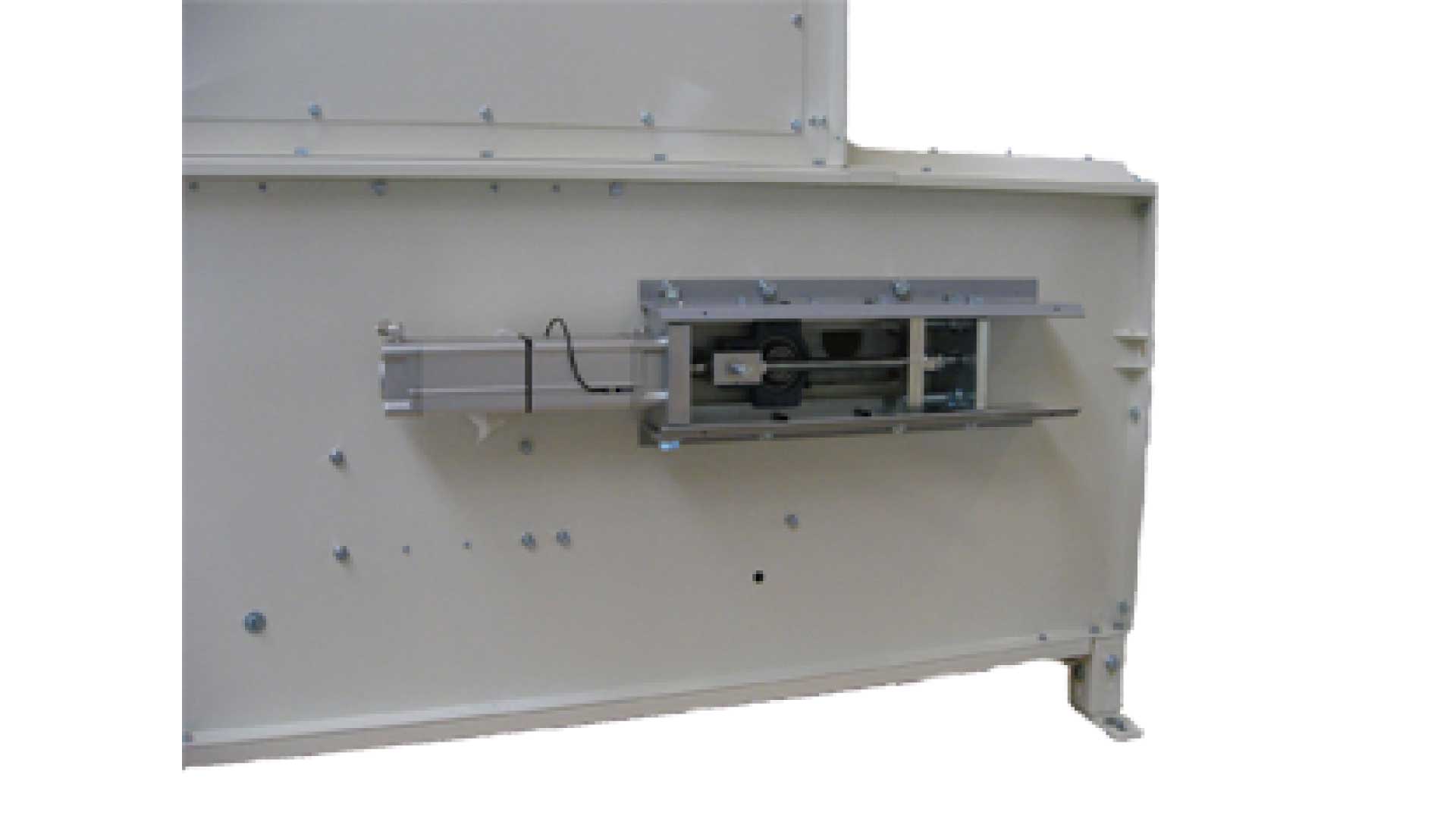

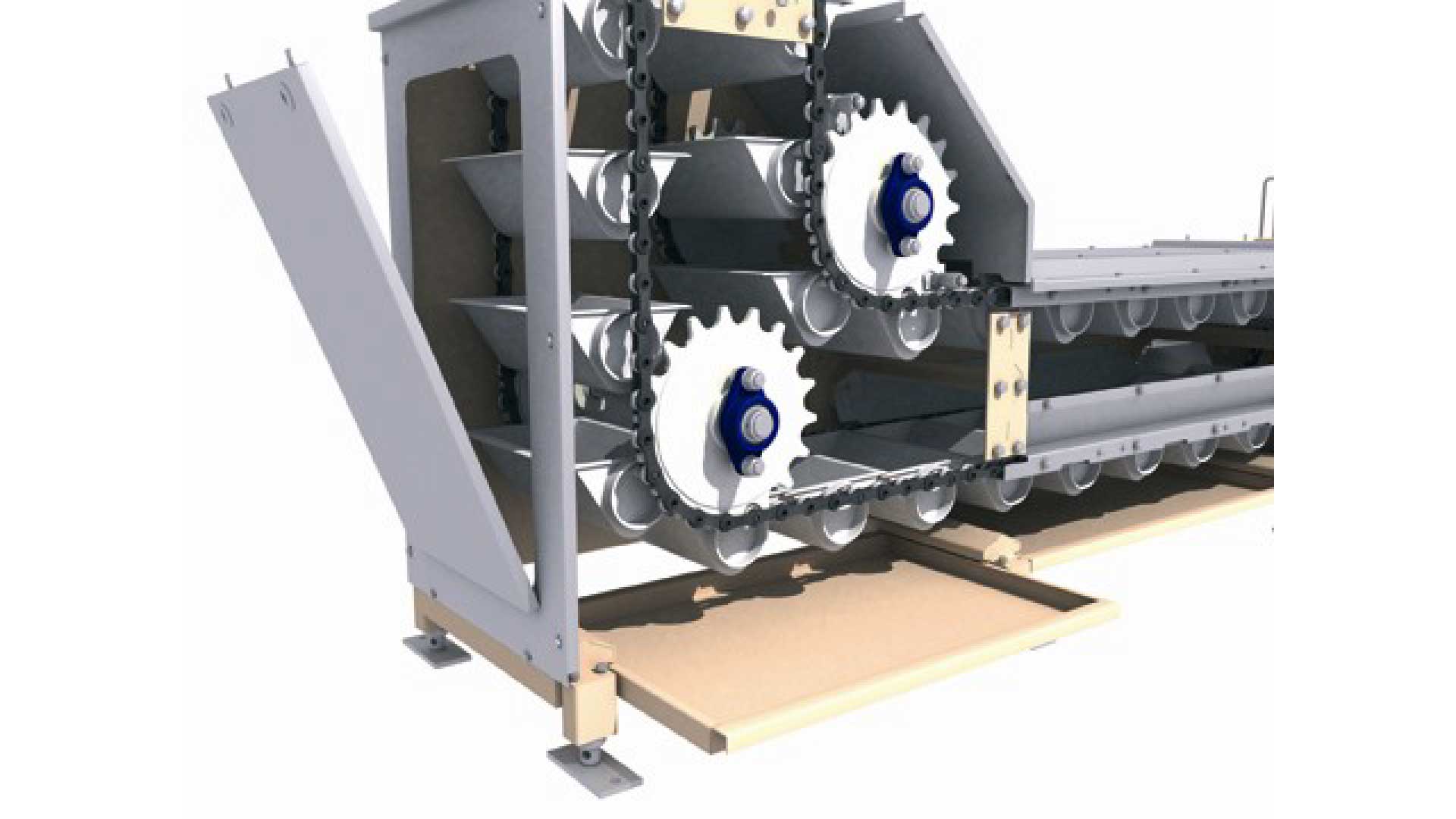

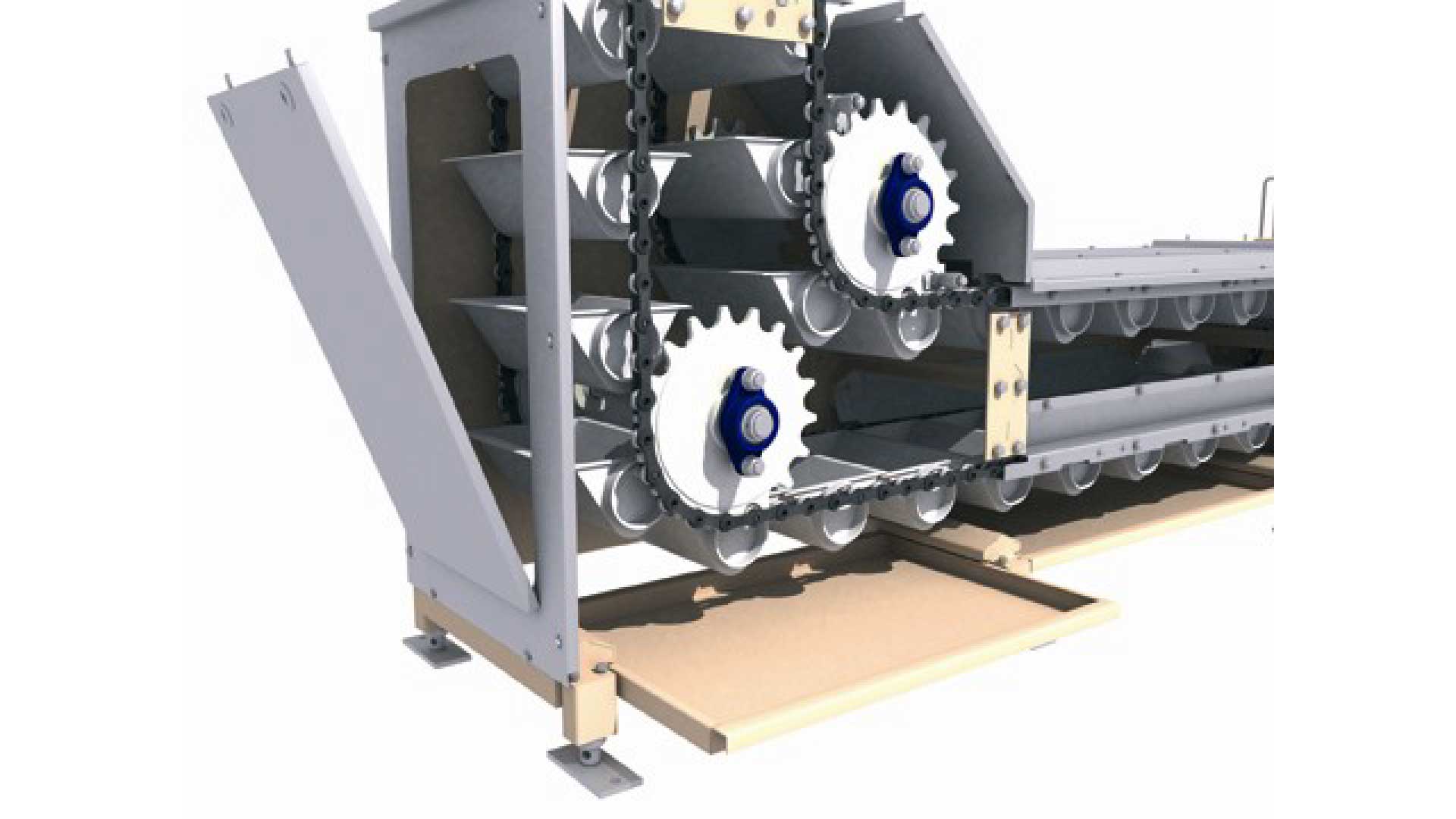

The different sections are assembled according to the form that fits each application, so that the design and construction of the elevator may be adapted according to existing requirements. When the sections have been assembled, two parallel running chains must be fitted and between these the buckets are placed in which the product is conveyed from the inlet to the outlet. The high quality roller chains are equipped with nylon rollers ensuring long service-life, less friction, and quiet operation. In the lower section, the bucket elevator has been equipped with chain guides and brushes that protect the chains against dust.

“I’m amazed you’ve managed to get these [four] Bucket Elevators installed within 4 weeks of order. We really didn’t think this was possible! Thank you all.”

Operations Manager, Snack Pack contract packer, UK

3

Different design variants to suit your needs

The standard “Universal” elevator is the traditional elevator and is used in a number of industries.

For hygienic conveying of bulk products the Sanitary Design can be used. The open design elevator is particularly suited for conveying food products, f.ex. snacks and pasta, and other products requiring hygienic conveying. Our Sanitary Design has an open frame and is produced in stainless steel. It is easy to clean manually both wet and dry. For automatic cleaning of buckets and chains an optional washing station (CIP) may be applied.

Our Basic Design applies especially to the light industry, small pelletising facilities and the agro industry. The concept is based on standard modules with the possibility of on-site length adjustments. The Universal Elevator Type 44G Basic is produced in galvanized steel plates. As an option it will be possible to have the plates enamelled. The Universal Elevator type 44G Basic is comparable to the Universal Elevator type 33E, but operates with larger buckets and therefore has 25% higher capacity.

Many bucket styles and materials

The buckets are suspended in pegs between two parallel running chains, and they are kept in a horizontal position from filling to emptying by gravitational force. The buckets move in a continuous system kept in place by pendular suspension between two parallel running chains from filling to emptying. In the horizontal sections, buckets overlap each other so that there is a continuous belt which prevents products from falling through the row of buckets. A capacity of 60 m³/h can be reached with the largest buckets with a cubic capacity of 20 litres and a chain speed of 21 m/min. Low speeds up to 21 m/min (0.3 m/sec) ensure careful handling of the products.

Highly configurable Construction Forms

The flexible modular system makes it possible to deliver a solution in which our customers’ individual transport needs are taken into consideration and met.

Inlets and outlets can be positioned according to customer requirements.

Cleaning in place

The CIP station is particularly developed for Simatek® Universal Elevators in order to ensure a simple and efficient cleaning of buckets and chains.

When using a CIP station, contamination, as a result of remaining residual products, will be avoided as well as the risk of product blending when running with different products.

The CIP station, in addition to the sanitary construction for manual cleaning of section parts, thus ensures the optimum solution for efficient and up-to-date sanitary conveying.

Suitable for a wide range of products

Simatek® Universal Elevators are applied all over the world by leading producers of fragile products such as enzymes, minerals, plant seeds, foods, pet food and aqua feed. With our flexible elevator construction forms we are able to accommodate almost any demands to in-house transportation.

UK agents

Want to find out more?

Controllers

Drive Section

Tension Adjustment

Intermediate Outlets

Inspection & Maintenance

ATEX

Special offer

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Quisque quis quis vestibulum magna.

Praesent id euismod mi, nec facilisis leo.

Get in touch

Contact Us

ADDRESS

Podmores (Engineers) Ltd

Unit H Great Fenton Business Park, Grove Road, Stoke, Staffordshire,

ST4 4LZ, UK

Solving automation problems since 1930