Rotary bowl feeders can sort, orientate and filter your product at lightning speed. They are excellent at delivering orientated product at high throughput rates.

| Frequency | 50Hz, 60Hz |

|---|---|

| IP Rating | IP00, IP20, IP54, IP65, IP66, IP67, IP68, IP69K |

| Materials | Aluminium, FDA Approved Plastics, FDA Rubber Lined, Mild Steel, Plastics, Rubber Lined, SS304, SS316L |

| Voltage | 230V, 415V |

Share

Learn more

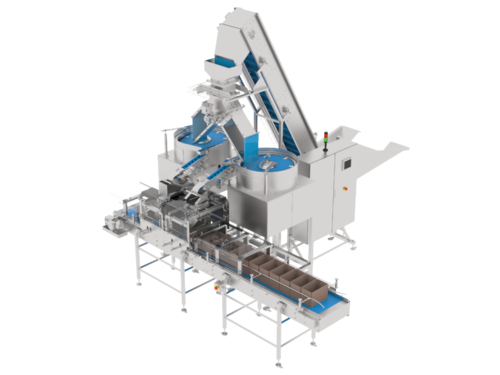

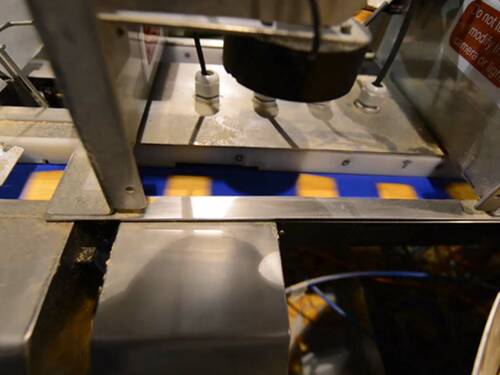

Ultra high speed product sorting

Reliable product infeed with a gentle yet high speed solution

Ultra high speed

Feed products at incredibly high speeds, creating a single stream of product that is correctly orientated to your needs.

Variable Speed

Wide adjustment range with ability to lock off settings to prevent unauthorised access.

Infeed Solutions

Podmores offer a wide range of bulk storage infeed solutions to reduce operator refill times.

Reliable

Podmores offer an industry leading reliable design proven for 24/7/365 operation in critical process conditions.

Low Noise Level

The emission sound pressure level of our standard Rotary Bowl Feeders is below 65 dB(A) at 1m distance, without product (Lpa re. 20µPa).

Low Running Cost

A basic Rotary Bowl Feeder costs as little as £0.20 per hour in operation.

Easy to clean

Hygienic design mean an easy to clean machine suitable for raw food contact and washdown environments.

Customised Solution

Podmores offer a customised solution to your materials handling needs.

Want to find out more?

Applications

- Biscuits

- Cheese

- Confectionary

- Food

- Frozen Meat

- Meat

- Pet food

- Snack Foods

- And more

Key benefits

Podmores range of Rotary Bowl Feeders are designed and built by our experienced team to give you the most reliable feeding system possible. Their high output speeds make them perfect for high speed packaging, inspection, printing, labelling and robotic automation applications. Rotary Bowl Feeders can be specifically manufactured for a wide range of products such as sausages, lids, confectionary bars, capsules etc.

- Ultra high speeds

- Creates a sorted stream of product.

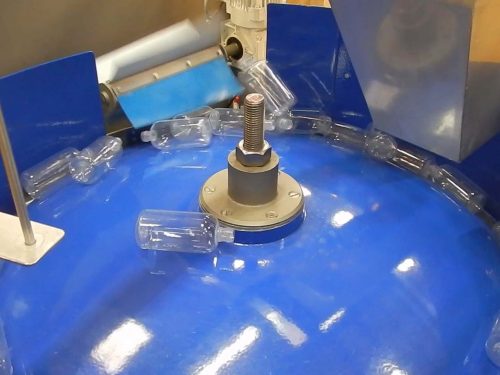

- Interchangeable or adjustable tooling for product format changeovers between similar products

- Constant feed rate that doesn't adjust over time.

- Compact design fits into existing production lines or new lines easily.

- Hygienic design and stainless steel contact materials available.

- Extremely quiet operation

- Vary speeds easily and simply.

- Optional hopper for product storage.

- Static or mobile versions available.

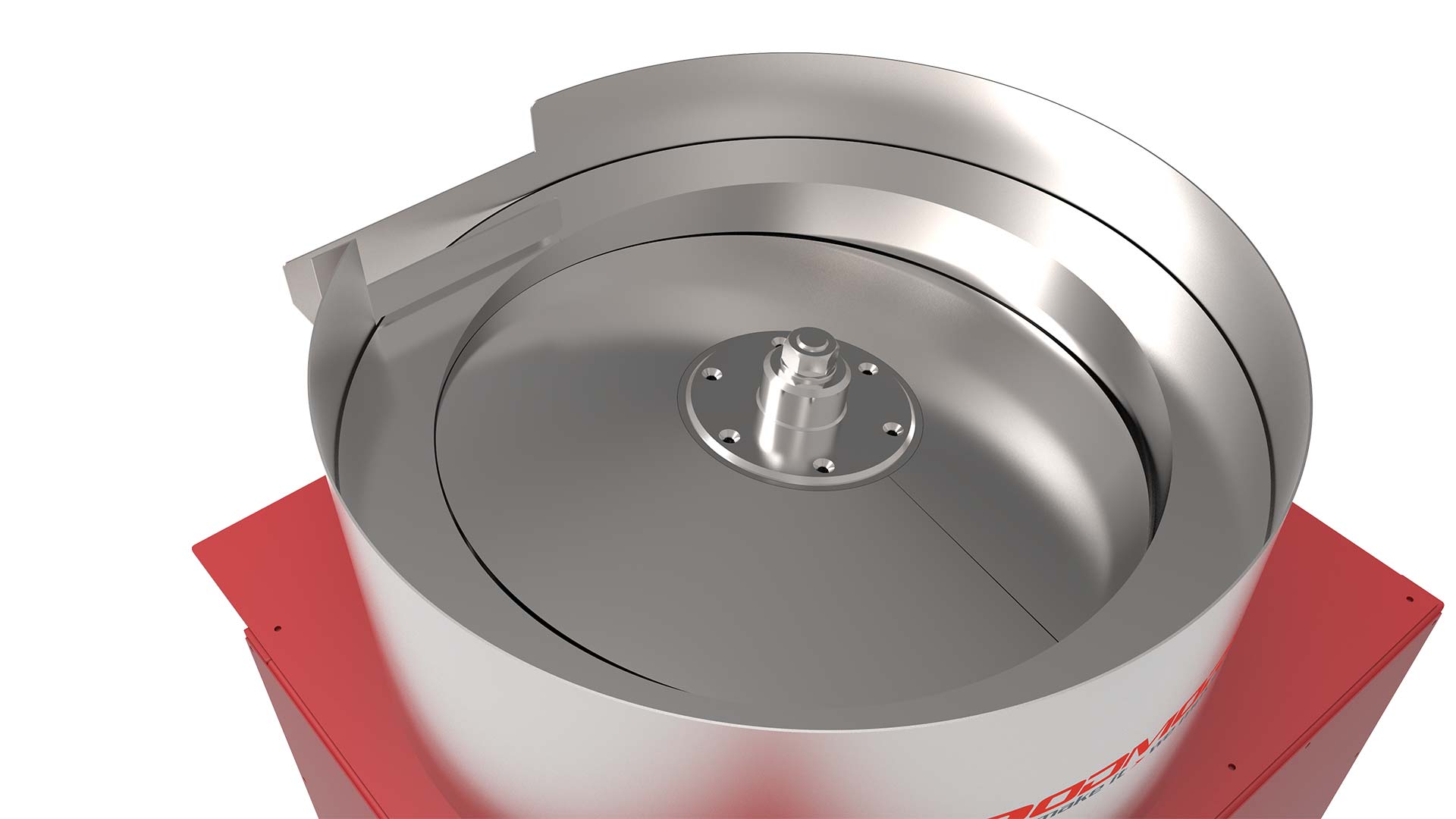

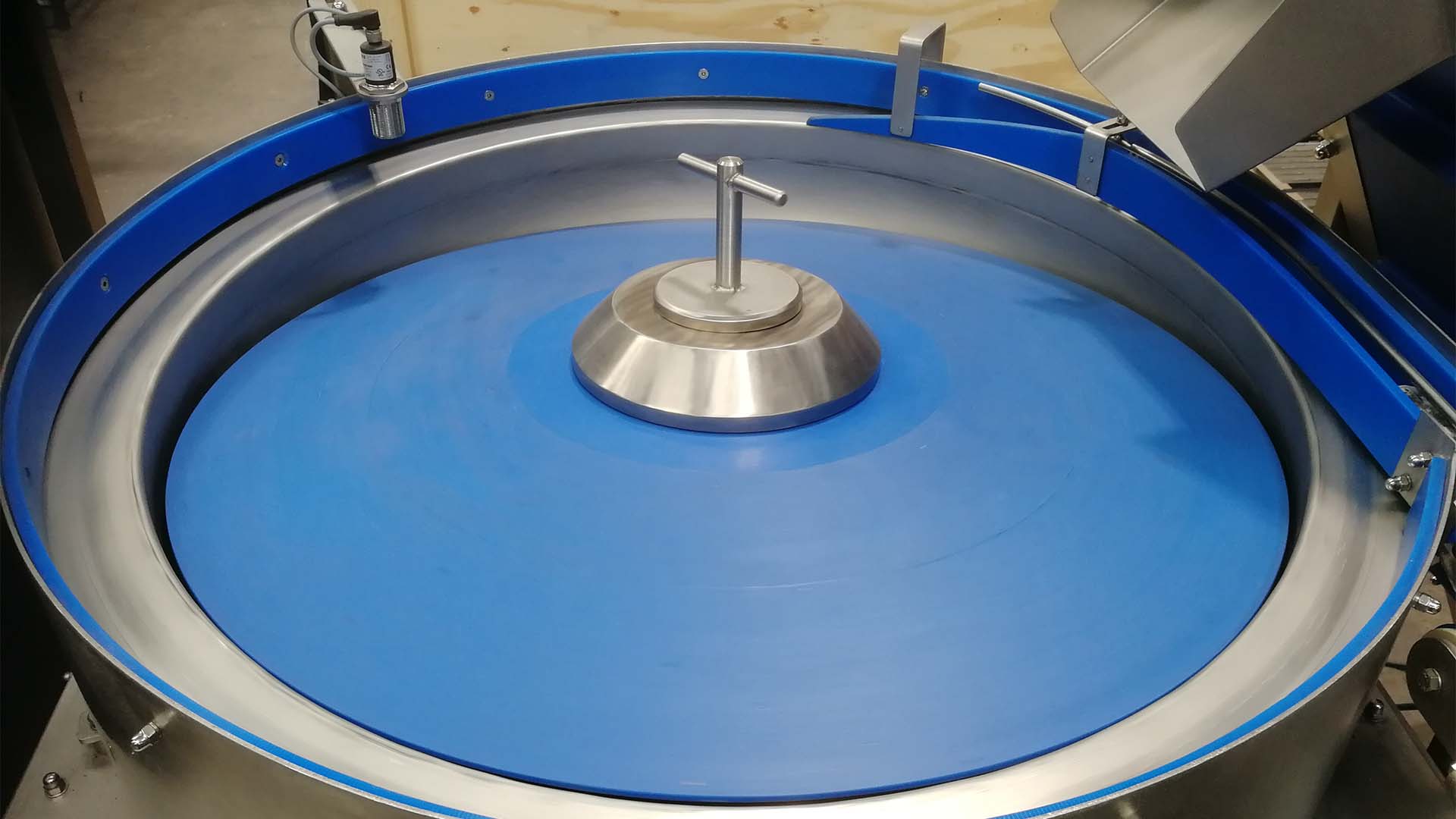

Outer ring for

final product selection

and transfer to

next machine

Inner ring for

buffer storage and

orientating product

A range of food

and non-food

configurations

are available

Proven Technology

Podmores Rotary Bowl Feeders are found in factories all over the world, from small businesses to household name companies. Podmores Rotary Bowl Feeders provide products as diverse as frozen and raw sausages, confectionary bars, snack foods and much more, and are trusted in critical production line processes. Their durable design means almost no downtime.

Optimised

A variety of tooling can be deployed to select the product in the orientation you require it, from simple tooling for regular shaped products like sausages through to vision systems where you require orientation based on logo/pack presentation as well.

Podmores can hep you deliver product exactly the way you require it so get in touch to find out how we can help with your product infeed requirements.

Gentle

Podmores Rotary Bowl Feeders offer an incredibly gentle solution to your products even while delivering ultra high speed outputs. Since 1930 we’ve handled almost every product imaginable. This experience and our testing/demonstration facilities allow us to prove to you that our solutions are the best option for our orientation and sorting needs.

Fill and forget

Our expertise with Storage & Infeed Systems allows us to deliver a solution no matter how much product you want to hold and how little you want to have to top the system up. Podmores can help you deploy storage solutions that keep your operatives free for other tasks around your factory.

Want to find out more?

Controllers

Orientation

Hygienic Design

ATEX

Get in touch

Contact Us

ADDRESS

Podmores (Engineers) Ltd

Unit H Great Fenton Business Park, Grove Road, Stoke, Staffordshire,

ST4 4LZ, UK

Solving automation problems since 1930