3 axis vibration for the most flexible feeding & sorting solution yet! A true innovation in the world of automation which offers unprecedented optimization of the feeding and sorting process.

| IP Rating | IP54 |

|---|---|

| Materials | Aluminium, FDA Approved Plastics, Mild Steel, Plastics, Rubber Lined, SS304, SS316L |

Share

Learn more

Videos

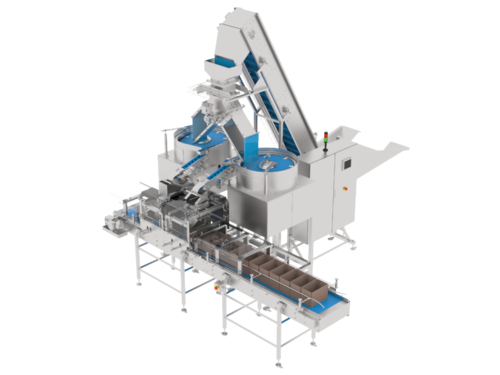

Vibratory Bowl Feeders

Find order from chaos

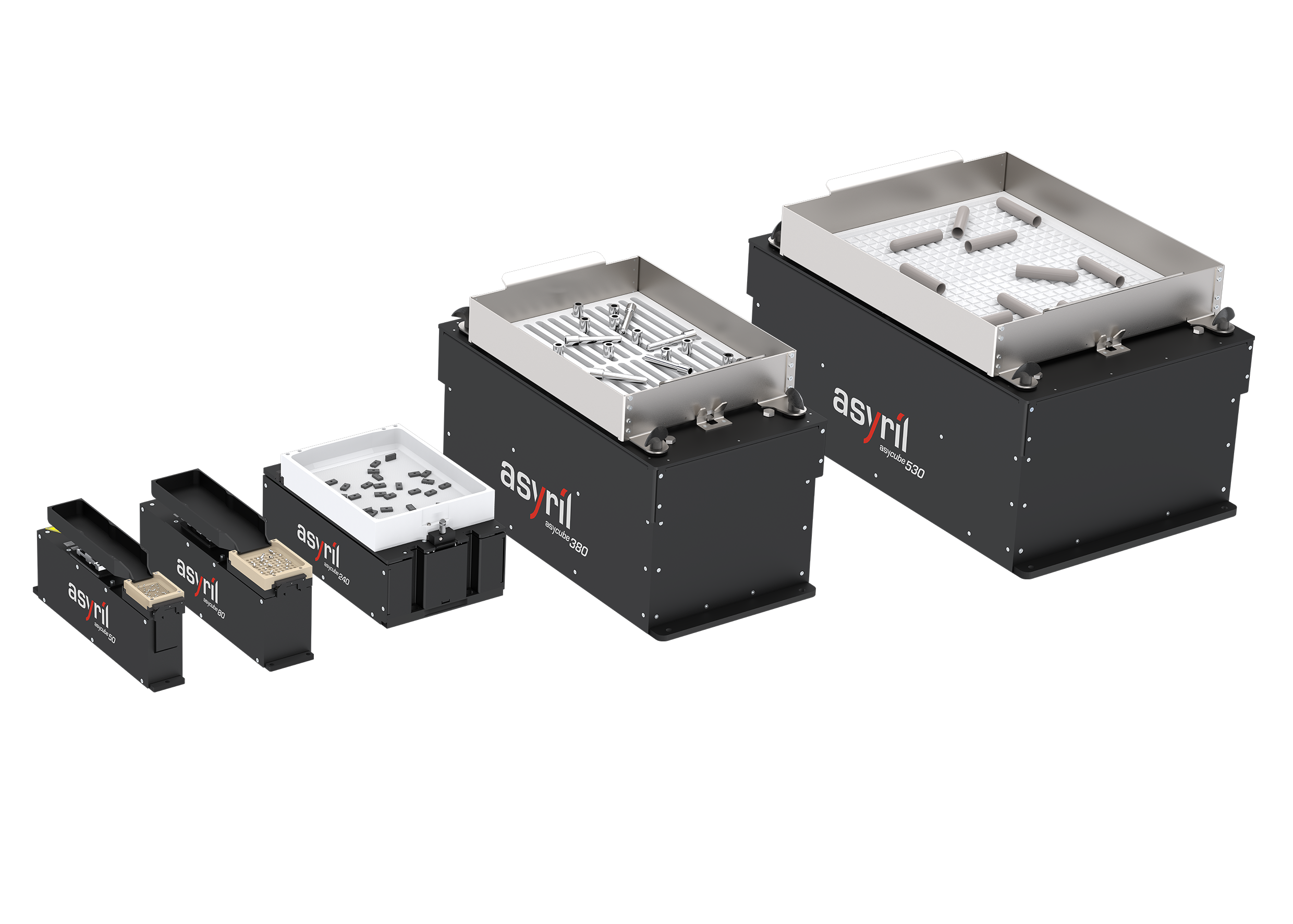

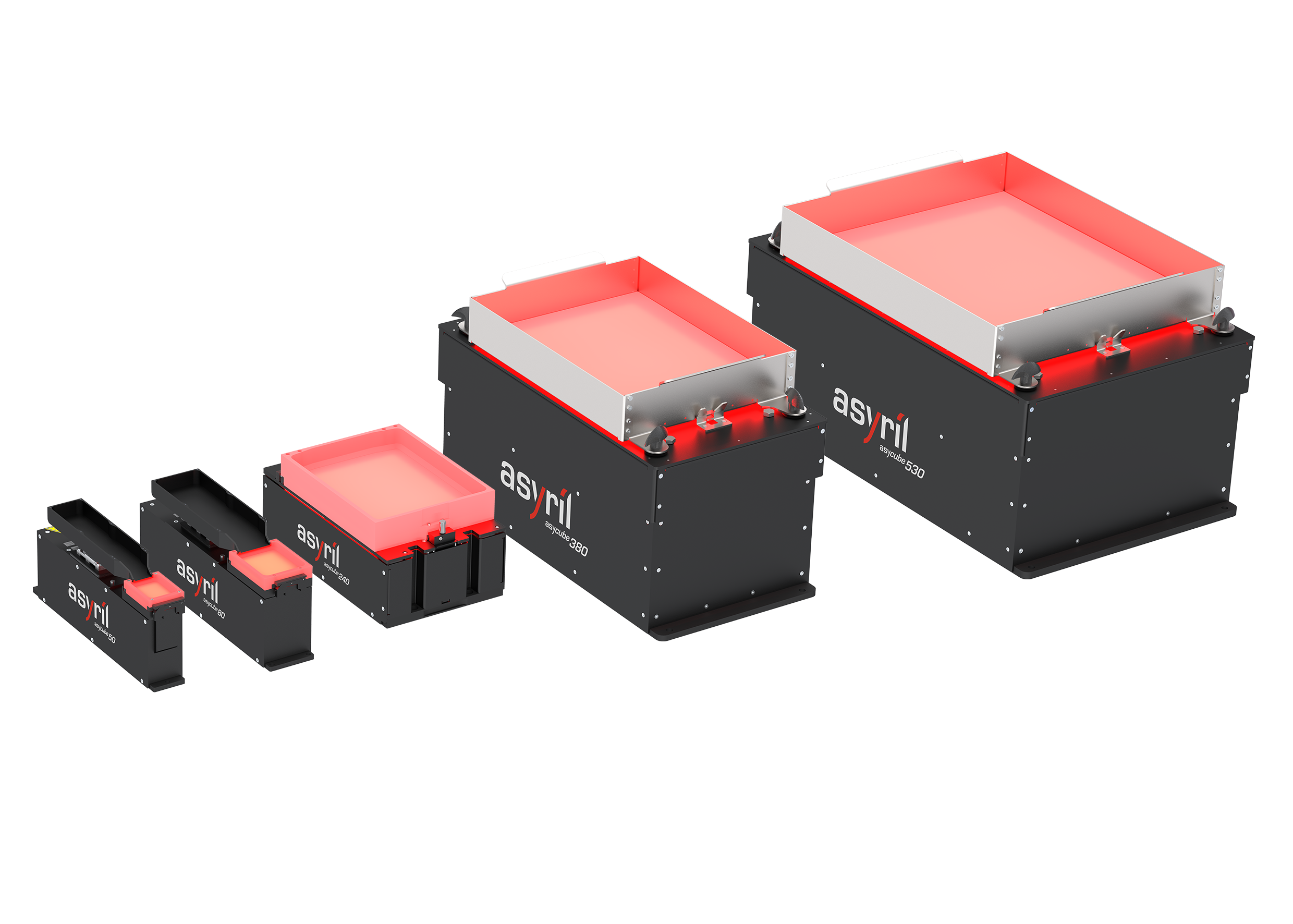

Based on a 3-axis vibration technology, Asyril’s flexible feeding systems represent a true innovation in the world of automation and offers unprecedented optimization of the feeding and sorting process.

This process allows parts to be moved in all directions, eliminates the accumulation of parts in a corner or on an edge, eliminates the recirculation of parts as well as handling delicate parts smoothly thanks to the precise adjustment of the frequency and amplitude.

Their technology is compatible with all part geometries. 99% of parts can be supplied by their flexible feeding systems, including parts with complex geometries and delicate materials.

UK partner

Flexible

Compatible with 99% of types of parts and geometries

Variable settings

Wide adjustment range with ability to lock off settings to prevent unauthorised access.

Infeed Solutions

Quick and easy changeover between products by saving past configurations.

Accurate Feeding

Vision validated orientation for precise component selection.

Low Noise Level

The emission sound pressure level is below 65 dB(A) at 1m distance, without product (Lpa re. 20µPa).

Low Running Cost

A Flex Feeder costs as little as £0.05 per hour in operation.

Short cycle times

Optimised performance to achieve incredibly short cycle times, allowing more time for the robot to work.

Customised Solution

Podmores offer a customised solution to your materials handling needs.

Want to find out more?

Applications

- Almost any component/product

- Aerospace components

- Automotive components

- Bottles

- Caps

- Confectionary

- Ecig

- Electrical components

- Food

- Lids

- Medical items

- Military

- Nutritional products

- Pharmaceutical products

- Plastic parts

- Primary packed products

- And more

Key benefits

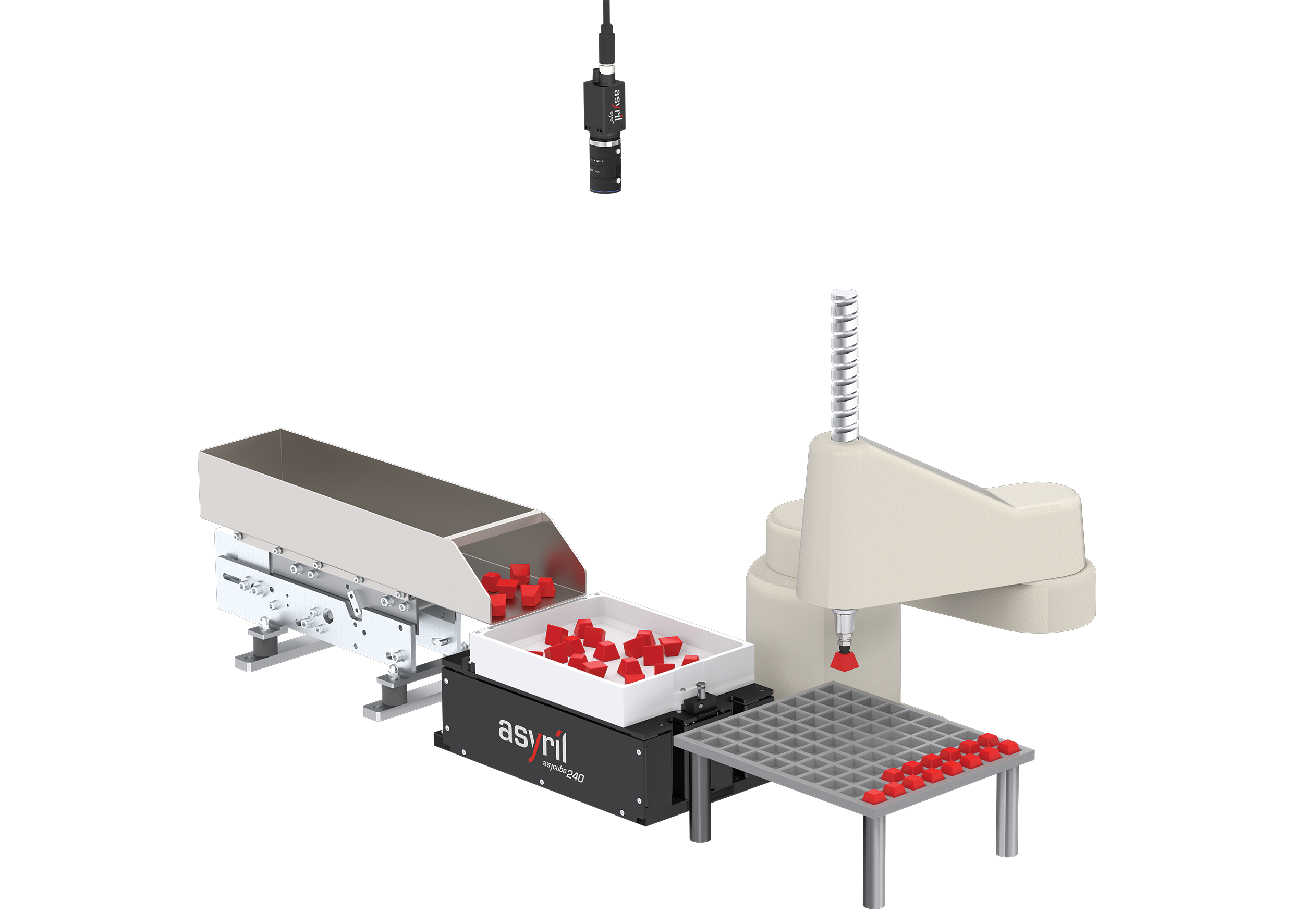

Asyril feeders’ can be used for components from 0.1 mm to 150 mm. They have developed vibratory parts feeders to offer an efficient solution for the unbulking of all types of components delivered in bulk. The Asycube is compatible with all robots and PLCs thanks to its TCP/IP and Modbus TCP compatible communication. Various plugins are available for easy system integration. Using Asyril’s EYE+ smart control system, will allow you to optimize the performance of your Asycube.

This system moves parts quickly in all directions, eliminates corner and edge build-up, eliminates part recirculation, and handles delicate parts smoothly with precise frequency and amplitude control. Asyril’s patented 3-axis technology allows better cycle times and optimal efficiency of your machine even on structured, slotted or perforated platforms. Quick and easy changeover from one series to another thanks to simple settings of different vibration recipes and tool-free platform change.

- Compatible with 99% of types of parts and geometries

- Short cycle times

- Pre-orientation and gentle separation of components thanks to patented 3-axis system

- Easy settings and integration

- Compatible with all types of robots and PLC

- Compact and flexible feeder with integrated controller

- Reduced production changeover time

- Swiss quality product with no maintenance required

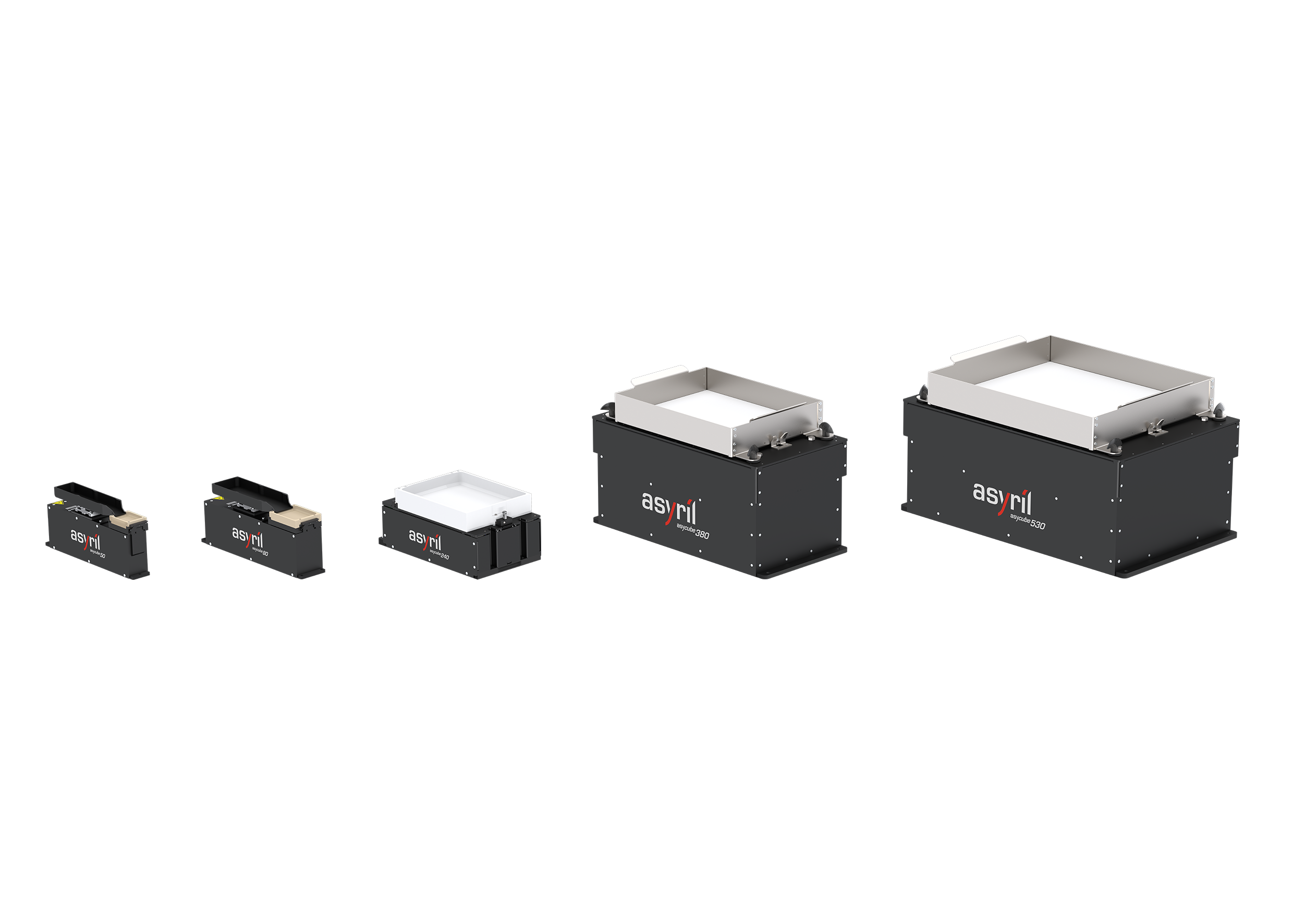

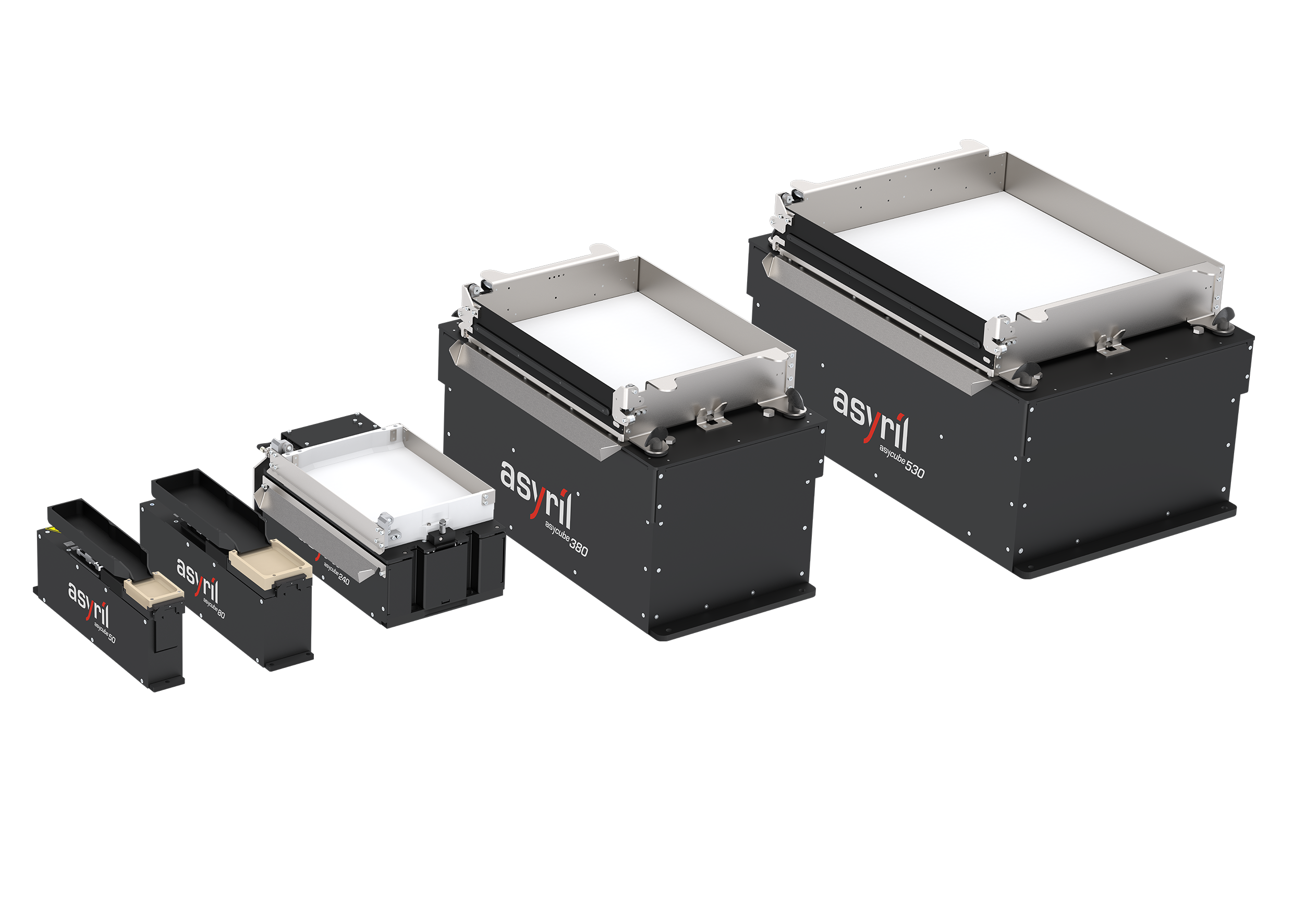

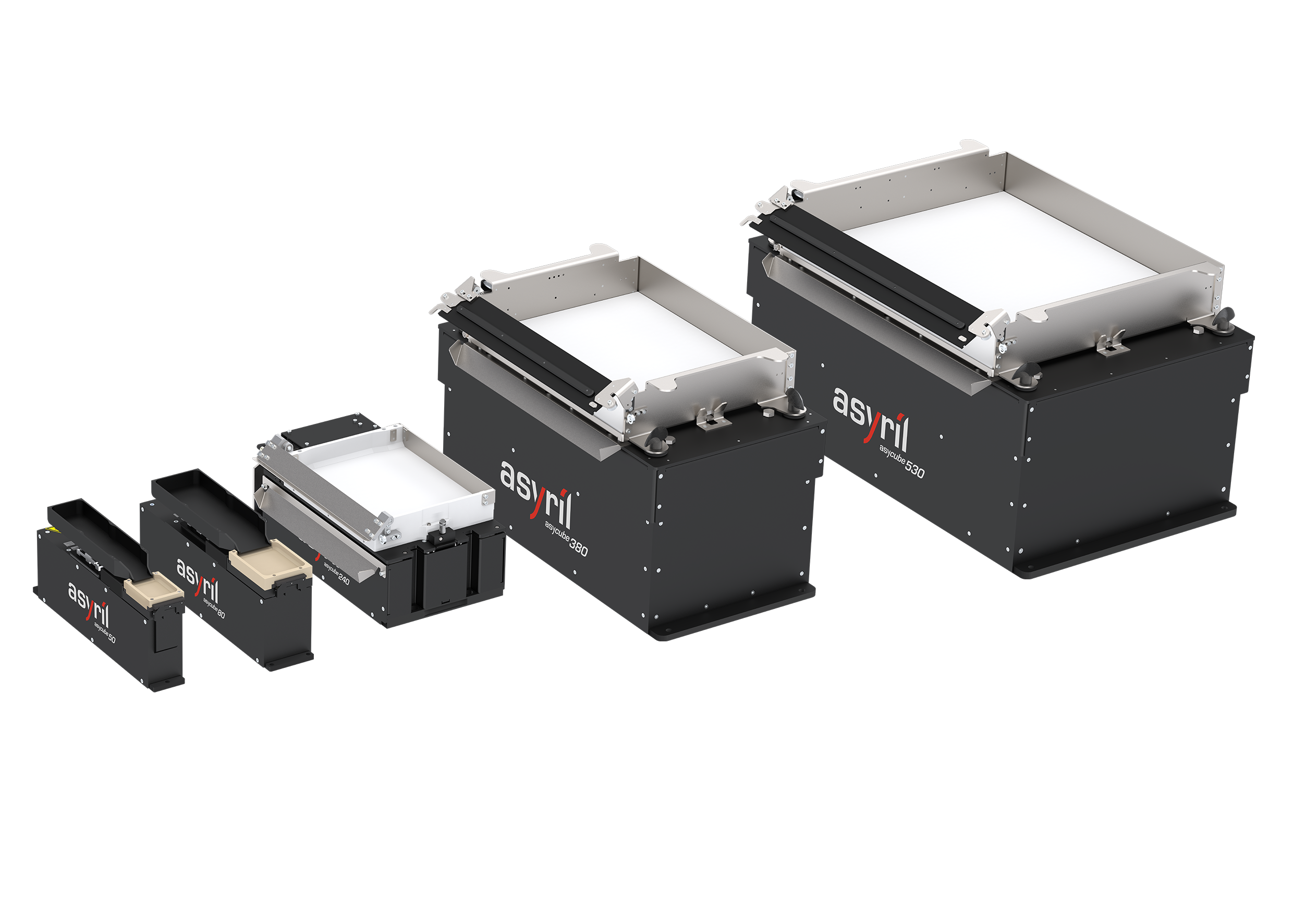

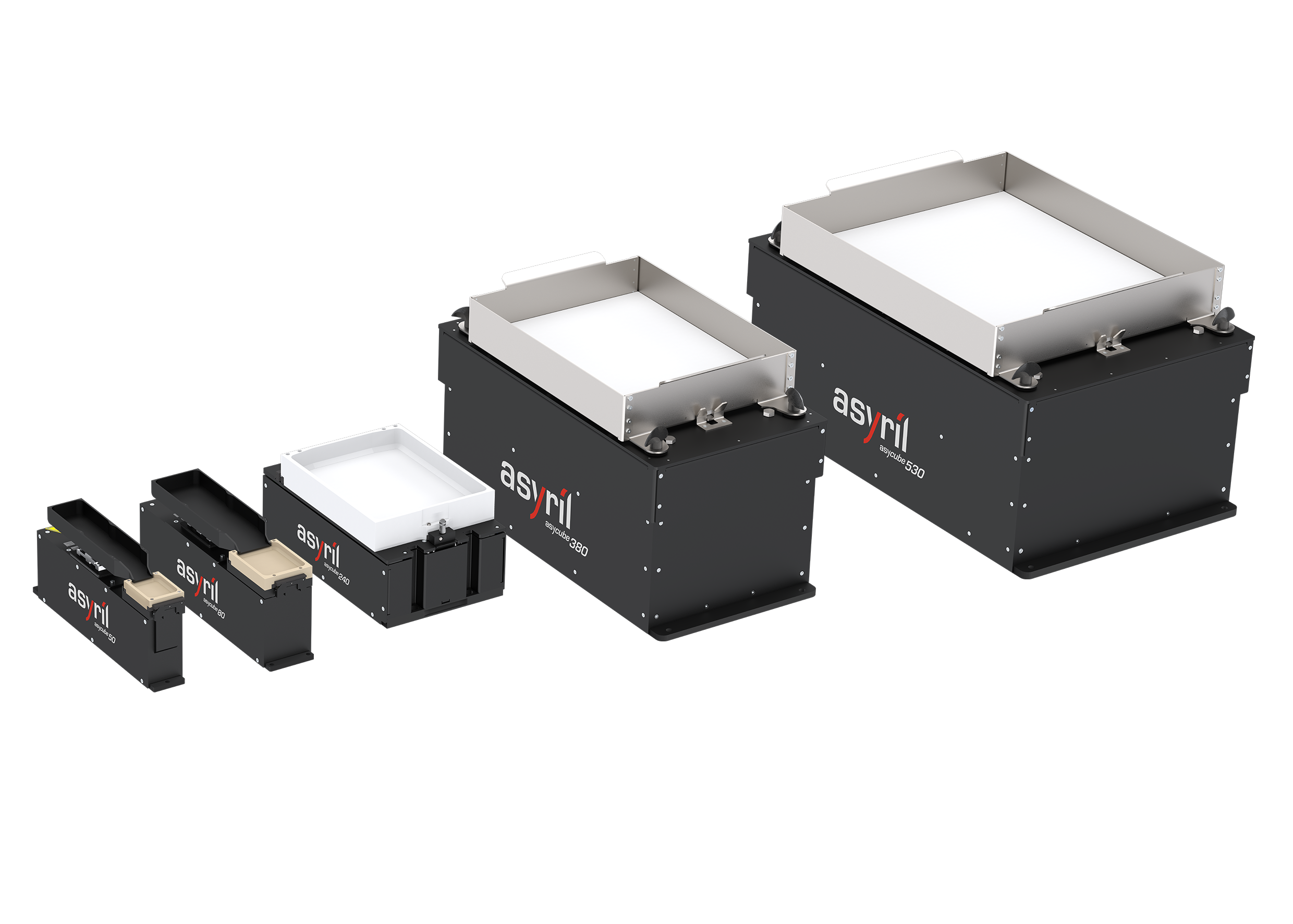

Asycube 50

The Asycube 50 flexible feeder is ideal for small flat or cubic components between 0.1 and 5 millimetres in size, such as gemstones, watch parts, small medical or electronic components.

Product Sizes

0.1mm – 5mm

Dimensions

Size of vibratory platform

45 x 34 mm; ~50 mm diagonal

1.3 x 1.8 in; ~2 in diagonal

Feeder size (L x W x H):

293 x 46 x 138 mm

11.5 x 1.8 x 5.4 in

Standard Hopper sizes

10 cm3 / 110 cm3

Asycube 80

The Asycube 80 flexible feeder is ideal for small flat or cubic components between 3 and 15 millimetres in size, such as gemstones, watch parts, small medical or electronic components.

Product Sizes

4mm – 15mm

Dimensions

Size of vibratory platform:

67 x 52 mm; ~80 mm diagonal

2.6 x 2.1 in; ~3.1 in diagonal

Feeder size (L x W x H):

320 x 61 x 138 mm

12.6 x 2.4 x 5.4 in

Standard Hopper size

160 cm3

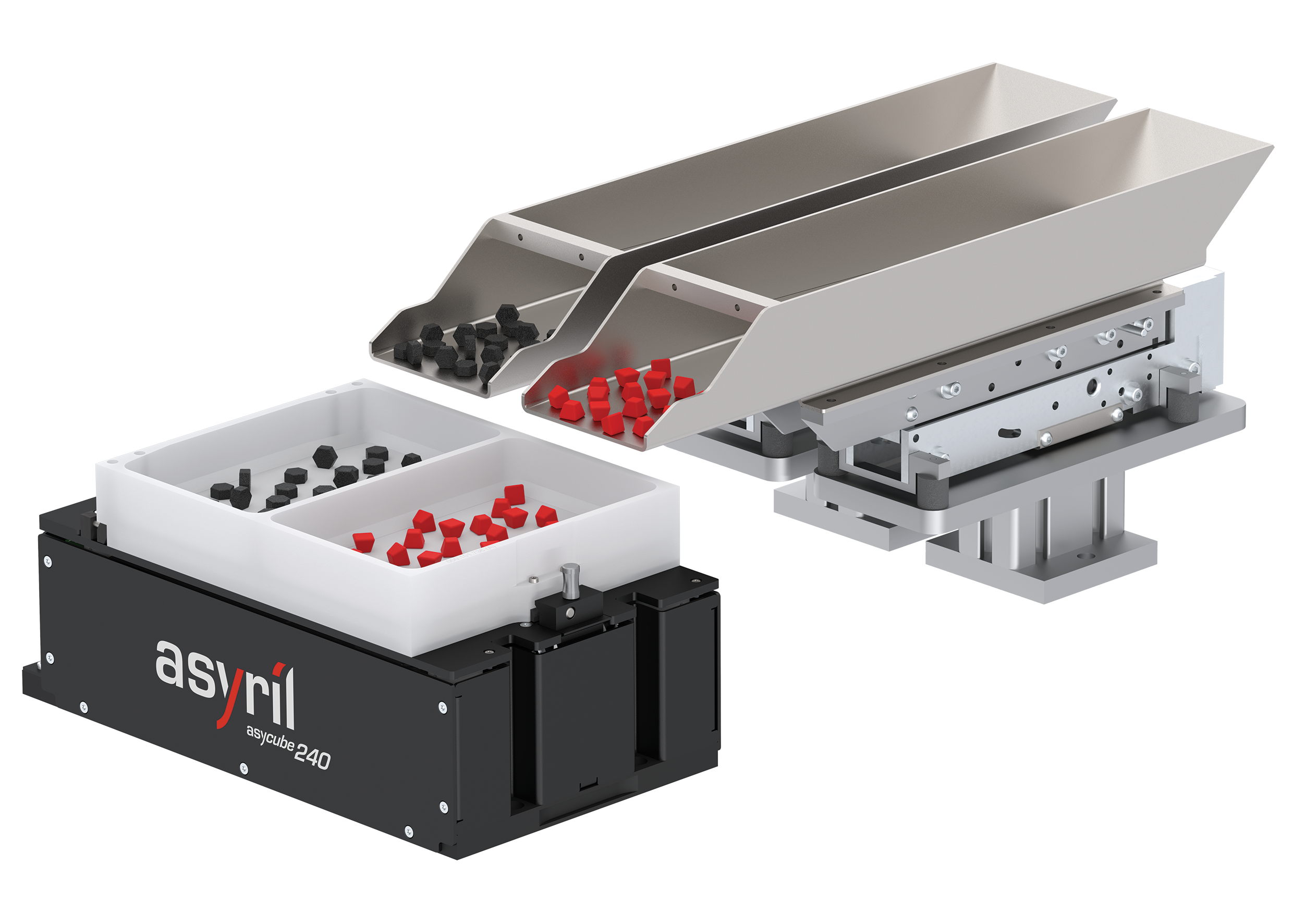

Asycube 240

The Asycube 240 flexible feeder is ideal for small flat or cubic components with a size between 5 and 40 millimetres, such as electronic components, fuses, screws, fasteners, washers.

Product Sizes

5mm – 40mm

Dimensions

Size of vibratory platform:

195 x 150 mm; ~240 mm diagonal

7.6 x 5.9 in; ~10 in diagonal

Feeder size (L x W x H):

300 x 171 x 132 mm

11.8 x 6.7 x 5.2 in

Standard Hopper sizes

2 litres / 3 litres

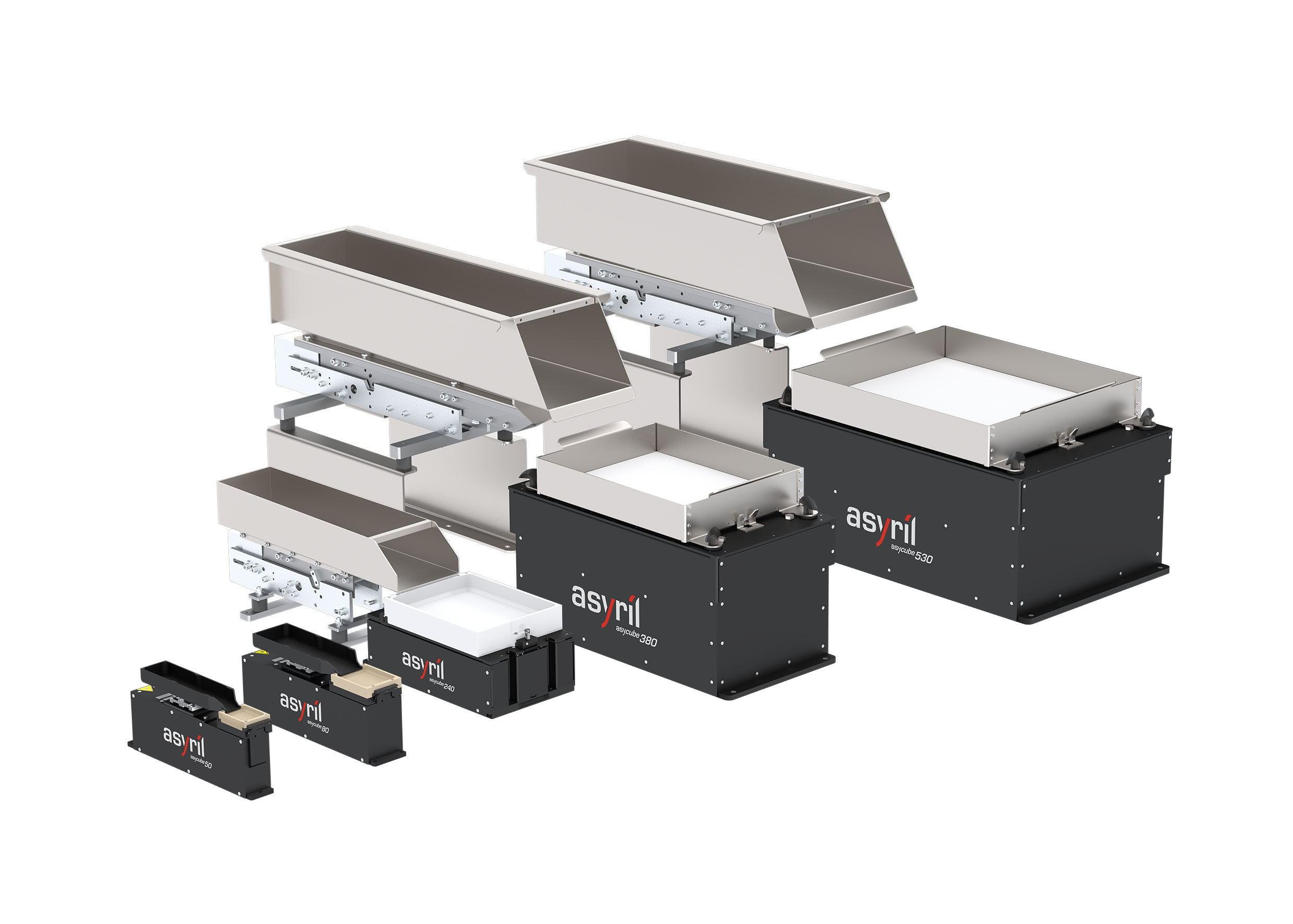

Asycube 380

The Asycube 380 flexible feeder is ideal for components between 15 and 60 millimetres in size, such as complex fasteners, large-volume parts, joints.

Product Sizes

15mm – 60mm

Dimensions

Size of vibratory platform:

254 x 325 mm; ~380 mm diagonal

10 x 12.8 in; ~14.96 in diagonal

Feeder size (L x W x H)

499 x 257 x 307 mm

19.6 x 10.1 x 12.1 in

Standard Hopper size

10 litres

Asycube 530

The Asycube 530 flexible feeder is ideal for components between 30 and 150 millimetres in size, such as large complex housings, bearings.

Product Sizes

30mm – 150mm

Dimensions

Size of vibratory platform:

427 x 371 mm; ~530 mm diagonal

16.8 x 14.6 in; ~20.9 in diagonal

Feeder size (L x W x H)

600 x 372 x 320 mm

23.7 x 14.7 x 12.6 in

Standard Hopper size

15 litres

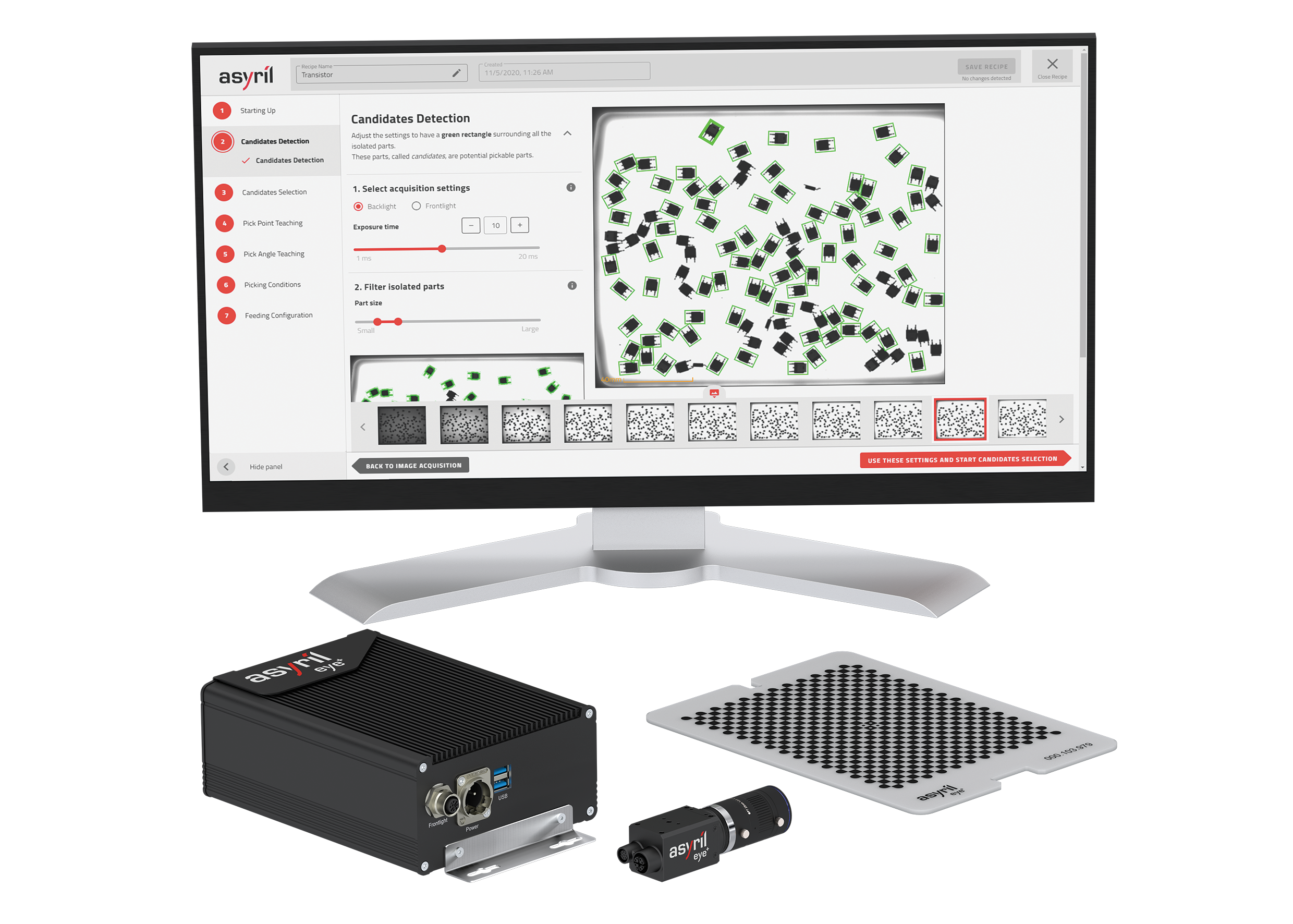

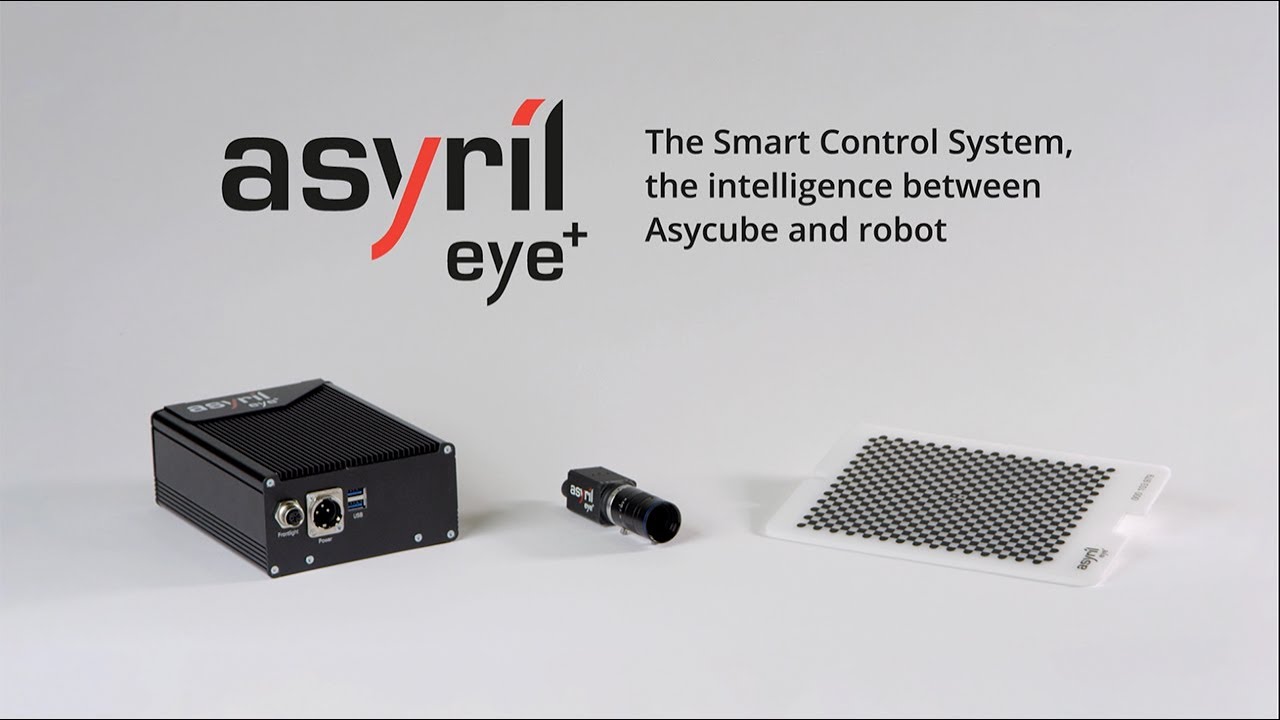

EYE+ smart control system

Bulk Hopper to store and

automatically top up the

Flexible Feeder

Flexible Feeder

Robot or pick and place

system

EYE+

EYE+, Asyril’s smart control system, is your partner for efficient production. It optimizes the performance of your Asycube with an integrated vision based on Artificial Intelligence and a powerful controller. This system allows the control of the hopper, the Asycube, the camera and the robot via the EYE+ Studio web interface.

With EYE+ you have an innovative plug and play system that can be easily integrated into any automation machine. No previous vision experience is required to set up and use EYE+ as it is simple and intuitive to use. It allows you to create and configure your recipes easily and in a few minutes, without additional costs, which ensures profitability when feeding parts in succession.

Changeover

Automatic purge variant can be selected to open one side of the Feeder and product can be automatically fed out, ready for the next product. There’s no need to manually remove product from the system.

DIFFERENT DESIGNS TO SUIT YOUR NEEDS

Custom structured platforms can be fitted to guide product into specific orientations ready for picking.

Asycube Studio

Asycube Studio is a simple to use software that allows complete setup of any Asycube series product with a direct connection.

For a complete recipe for any part, three easy steps are completed through a wizard, platform vibrations optimized for part movement, hopper management and vibration sequence. Click here to download Asycube Studio. For complete flexible feeding management, we recommend using EYE+.

Downloads

UK partner

Want to find out more?

Related products

Get in touch

Contact Us

ADDRESS

Podmores (Engineers) Ltd

Unit H Great Fenton Business Park, Grove Road, Stoke, Staffordshire,

ST4 4LZ, UK

Solving automation problems since 1930