Similar to our range of vibratory bowl feeders, centrifugal bowl feeders operate in tougher conditions and with products normally considered unsuitable for bowl feeding. Great for greasy or oil coated products, our centrifugal bowl feeders operate by moving all of the product to the outside of the bowl drum where they are orientated using a variety of mechanical tooling to deliver a high speed and accurate output.

| Frequency | 50Hz, 60Hz |

|---|---|

| IP Rating | IP54, IP65, IP66, IP67, IP68, IP69K |

| Materials | Aluminium, FDA Approved Plastics, FDA Rubber Lined, Mild Steel, Plastics, Rubber Lined, SS304, SS316L |

| Voltage | 110V, 230V, 415V |

Share

Learn more

Rapid product sorting and orientation

Deliver product in the correct orientation quickly, simply and gently.

Even Feeding

Ensure a full width delivery of product with spacing between each product

Variable Speed

Wide adjustment range with ability to lock off settings to prevent unauthorised access.

Infeed Solutions

Podmores offer a wide range of bulk storage infeed solutions to reduce operator refill times.

Reliable

Podmores offer an industry leading reliable design proven for 24/7/365 operation in critical process conditions.

Low Noise Level

The emission sound pressure level of all our Laners is below 65 dB(A) at 1m distance, without product (Lpa re. 20µPa).

Low Running Cost

A basic Laner costs as little as £0.20 per hour in operation.

Easy to clean

No moving parts and our hygienic design mean an easy to clean machine suitable for raw food contact.

Customised Solution

Podmores offer a customised solution to your materials handling needs.

Want to find out more?

Applications

- Almost any component/product

- Bottles

- Caps

- Confectionary

- Dairy

- Ecig

- Electrical components

- Food

- Lids

- Medical items

- Military

- Nutritional products

- Pharmaceutical products

- Plastic parts

- And more

Key benefits

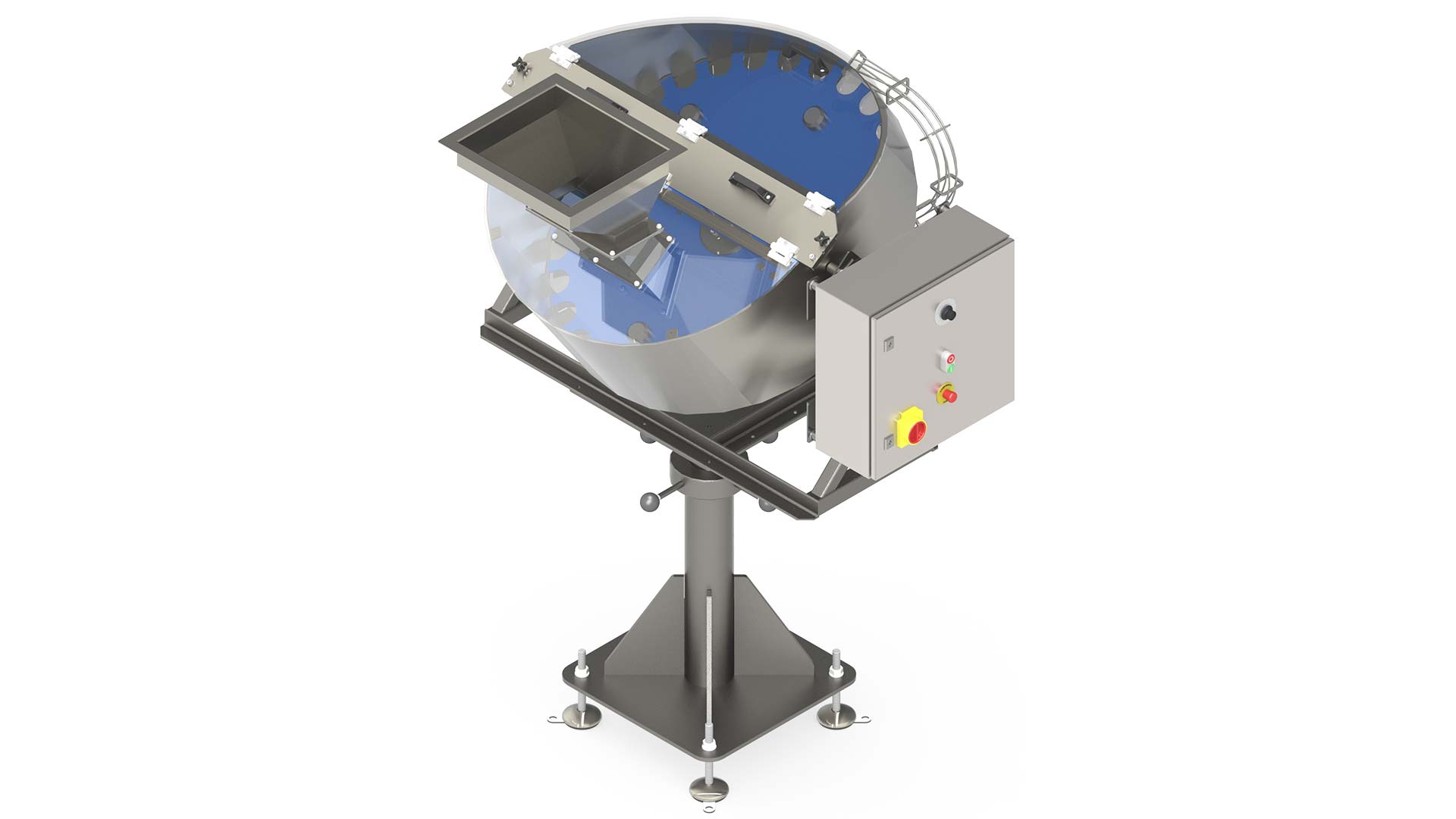

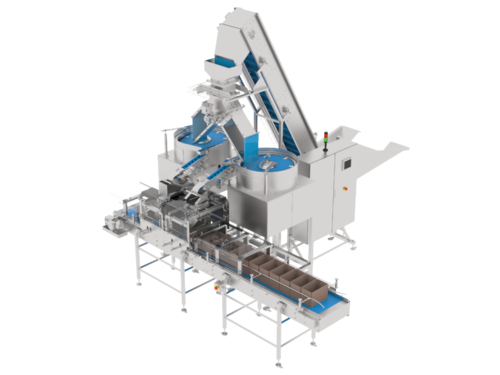

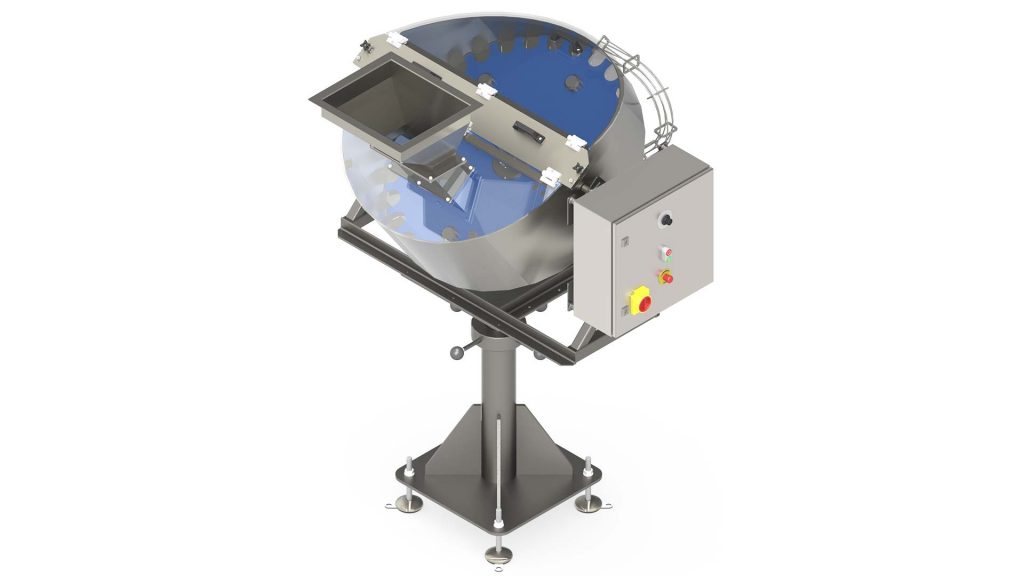

Centrifugal Bowl Feeders can be supplied as standalone units, or be incorporated into Cap/Lid Application Systems or Automated Systems. Podmores’ Centrifugal Bowl Feeders can be fabricated from stainless steel, mild steel, aluminium or plastics (including FDA approved) with sizes: 500mm-1,500mm diameter.

Using a rotary disc, machined to the specific profile of your product’s geometry a Centrifugal Bowl Feeder can achieve considerable throughput speeds whilst still featuring a low maintenance, easy to operate construction.

- Sort items into uniform streams.

- Orientate almost any shape of item

- Interchangeable rotating discs for quick product format changeovers.

- Vary speeds easily and simply.

- Moving parts guarded with safety cut-offs.

- Constant feed rate that doesn't adjust over time.

- Compact design fits into existing production lines or new lines easily.

- Hygienic design and stainless steel contact materials.

- Optional hopper for product storage.

- Static or mobile versions available.

Inlet chute

Control Panel

can be local or

remote

Outlet chute

to guide product

to the next process

Fixed or adjustable

height frames available

Interchangeable

rotating disc

Proven Technology

Podmores Centrifugal Bowl Feeders are found in factories all over the world, from small businesses to household name companies. Podmores Centrifugal Bowl Feeders provide bottle caps, lids, bottles, pots, jars, tablets and much more, and are trusted in critical production line processes. Their durable design means almost no downtime.

Optimised

Orientate almost any product quickly and efficiently in our centrifugal bowl feeders. Even greasy or oily coated products can be orientated however you need.

Gentle

Podmores Centrifugal Bowl Feeders have been used for product as gentle as pharmaceutical tablets, to sort and orientate them at high speed ready for printing a code onto them. The design of the machine provides very gentle product handling, suitable for almost any product.

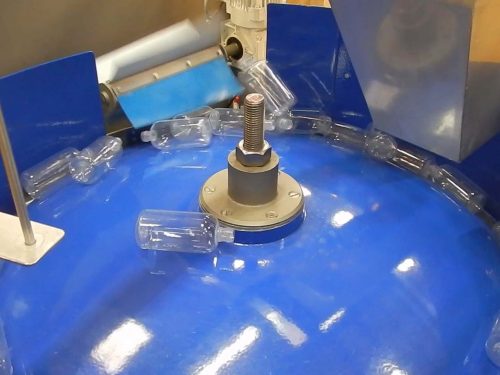

Pharmaceutical range

Our Pharmaceutical variant is suitable for high speed sorting and singulation of tablets and other pharmaceutical and medical products. This photo shows a small batch run tablet that required a code printing on each tablet The Centrifugal Bowl Feeder was perfect for achieving accurate printing on more than 12 tablets per second (730/minute)!

Fill and forget

Our expertise with Storage & Infeed Systems allows us to deliver a solution no matter how much product you want to hold and how little you want to have to top the system up. Podmores can help you deploy storage solutions that keep your operatives free for other tasks around your factory.

Want to find out more?

Controllers

Orientation

Output

Flexible

Hygienic Design

ATEX

Get in touch

Contact Us

ADDRESS

Podmores (Engineers) Ltd

Unit H Great Fenton Business Park, Grove Road, Stoke, Staffordshire,

ST4 4LZ, UK

Solving automation problems since 1930