Delivers targeted dusting of your product in a quick, clean and safe way. Our Dusting Machines have a major advantage over a spreader machine or doing it by hand; the targeted chutes provide the right amount of dusting in the right place and not around the product.

| Frequency | 50Hz, 60Hz |

|---|---|

| IP Rating | IP54, IP65, IP66, IP67 |

| Materials | Aluminium, FDA Approved Plastics, FDA Rubber Lined, Mild Steel, Plastics, Rubber Lined, SS304, SS316L |

| Voltage | 110V, 230V, 415V |

Share

Learn more

Videos

Sprinkling, Spreading & Depositing

Dusting your products with delicate precision

Whether it’s a light dusting of sugar snow or a coarse application of corn-starch, Podmores’ Dusting Machines can help.

Even Feeding

Ensure a full width delivery of product with optional guide nozzles for targeted application.

Variable Speed

Wide adjustment range with ability to lock off settings to prevent unauthorised access.

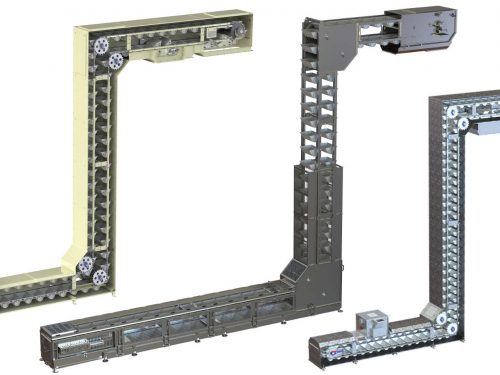

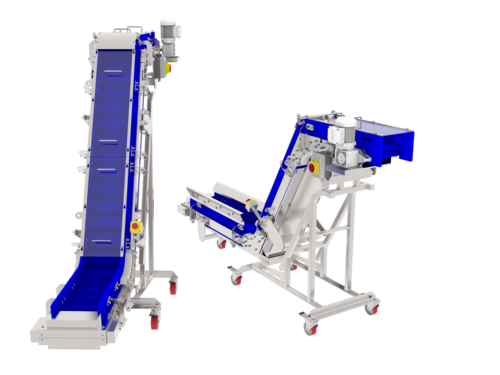

Infeed Solutions

Podmores offer a wide range of bulk storage infeed solutions to reduce operator refill times.

Reliable

Podmores offer an industry leading reliable design proven for 24/7/365 operation in critical process conditions.

Low Noise Level

The emission sound pressure level of basic our Dusting Machines is below 65 dB(A) at 1m distance, without product (Lpa re. 20µPa).

Low Running Cost

A basic Dusting Machine costs as little as £0.08 per hour in operation.

Easy to clean

Hygienic design mean an easy to clean machine suitable for raw food contact.

Customised Solution

Podmores offer a customised solution to your materials handling needs.

Want to find out more?

Applications

- Bakery

- Biscuits

- Building Materials

- Cheese

- Confectionary

- Food

- Inclusions & Toppings

- Pizza

- And more

Key benefits

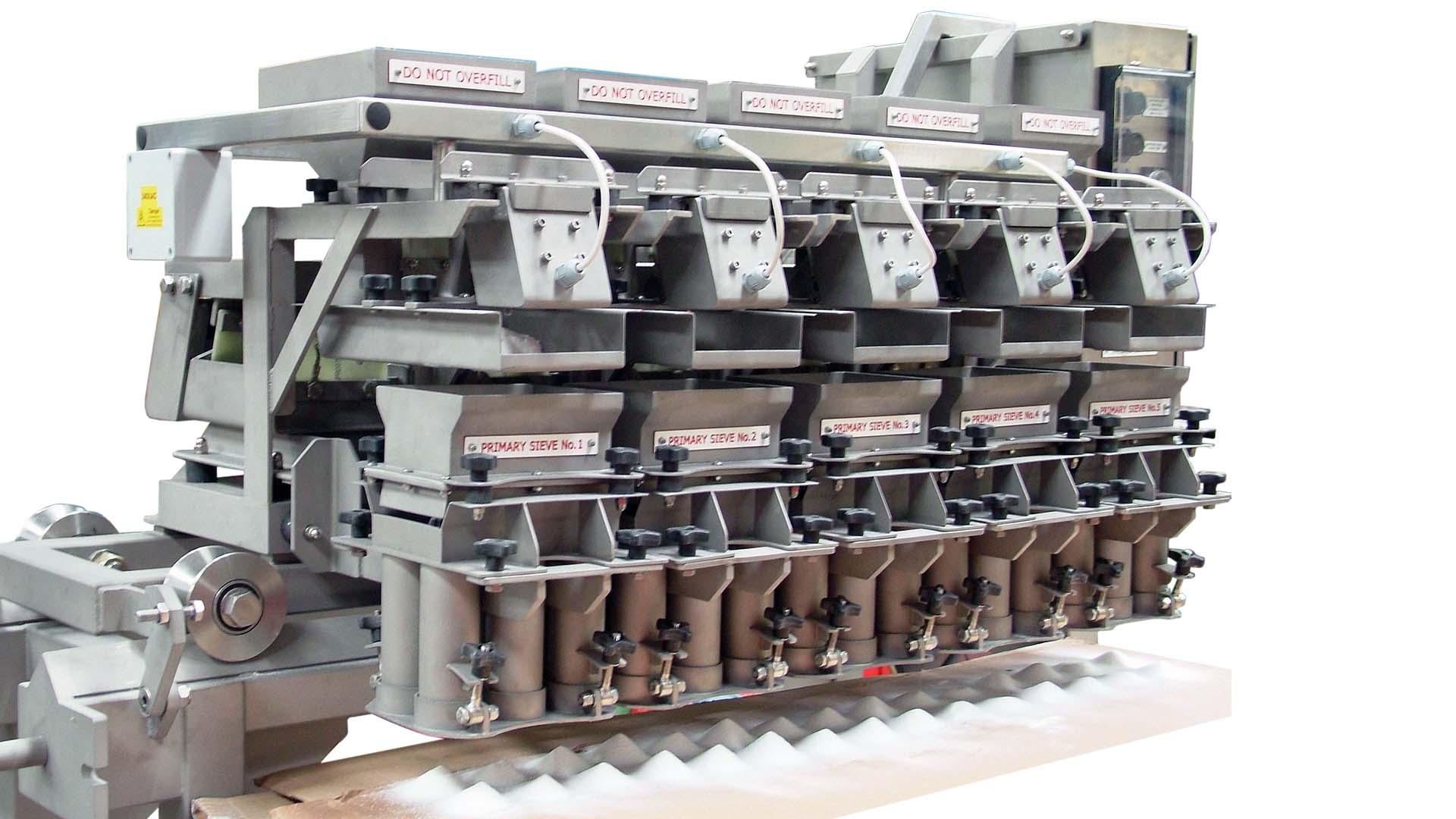

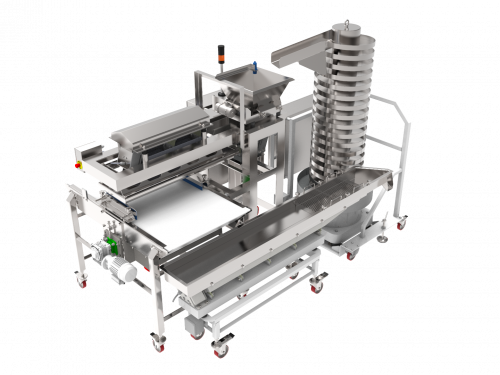

Podmores Dusting Machines provide an efficient system for delivering targeted dusting of your product in a quick, clean and safe way. Our machines have a major advantage over a Spreader Machine for hydroscopic products, or doing it by hand; the targeted chutes provide the right amount of dusting in the right place and not around the product. There are also considerable man-power savings to be had with a Podmores machine. Where it might have taken four or six operators to dust a stream of product, with a Podmores machine you only need one operative checking the hopper levels when they are alerted to a low level. Because of the often seasonal nature of dusting, most commonly seen on mince pies, our machines can be made to roll off and roll on to production lines, for storage and deep cleaning.

Available in almost any size and configuration, Podmores can build a dusting machine to your exact specification.

- Vary the amount of topping applied easily & quickly.

- Creates an even and consistent dusting of your product.

- Guide nozzles available for targeted dusting.

- Constant feed rate that doesn't adjust over time.

- Compact design fits into existing production lines or new lines easily.

- Hygienic design and stainless steel contact materials.

- Gentle handling reduces defects

- Confined process with no dust

- Optional hopper for product storage.

- Optional screening to remove large oversize product.

- Static or mobile versions available.

Height adjustment

available

Safety interlocked

hopper for buffer

storage of product

Mobile or static

versions available

Hygienic washdown

versions available

Proven Technology

Podmores Dusting Machines are found in factories all over the world, from small businesses to household name companies. Podmores Dusting Machines provide the sugar snow on your mince pies, paprika on smoked cheese, brick dust onto bricks and much more, and are trusted in critical production line processes. Their durable design means almost no downtime.

Customisable

Nozzles can be selected to direct your product exactly where you want it, reducing over dusting and reducing wastage. Nozzles can be fixed or adjustable, and interchangeable nozzles can be supplied to suit multiple product formats.

Fill and forget

Our expertise with Storage & Infeed Systems allows us to deliver a solution no matter how much product you want to hold and how little you want to have to top the system up. Podmores can help you deploy storage solutions that keep your operatives free for other tasks around your factory.

Want to find out more?

Hygienic Design

ATEX

Controllers

Get in touch

Contact Us

ADDRESS

Podmores (Engineers) Ltd

Unit H Great Fenton Business Park, Grove Road, Stoke, Staffordshire,

ST4 4LZ, UK

Solving automation problems since 1930