Ensure high-speed quality control by deploying a 100% inspection solution by Podmores. Our systems have been developed over the years in a wide range of industries including food, beverage, pharmaceutical and automotive.

Share

Learn more

Videos

Sprinkling, Spreading & Depositing

Ensure quality and sort products using the latest tech

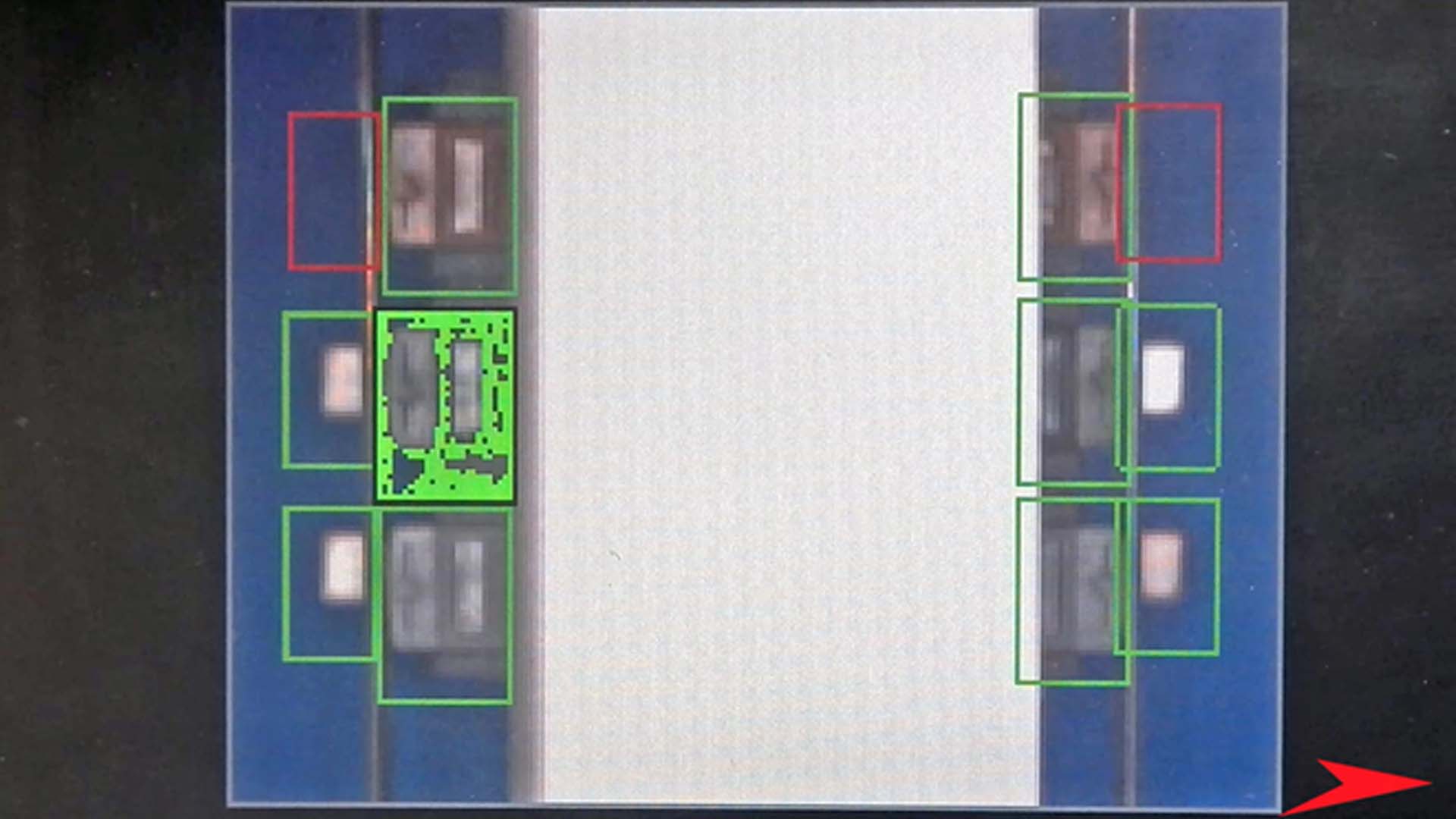

Modern vision systems allow incredibly advanced technologies and ultra high speed processing to check every part of your product quickly.

Rapid ROI

Achieve ROI almost instantly. Most customers hit ROI within 12 months.

Quality Assurance

Peace of mind from knowing that your product(s) are all checked for quality.

Range of solutions

Podmores can work with a wide range of vision system providers, ensuring the best solution is deployed.

Reliable

Podmores offer an industry leading reliable design proven for 24/7/365 operation in critical process conditions.

Low Noise Level

The emission sound pressure level of our Vision System rejects is below 70 dB(A) at 1m distance, without product (Lpa re. 20µPa).

Low Running Cost

A basic Vision System costs as little as £0.01 per hour in operation.

Easy to clean

We can deploy a hygienic design solution suitable for raw food contact.

Customised Solution

Podmores offer a customised solution to your materials handling needs.

Want to find out more?

Applications

- Almost any component/product

- And more

Key benefits

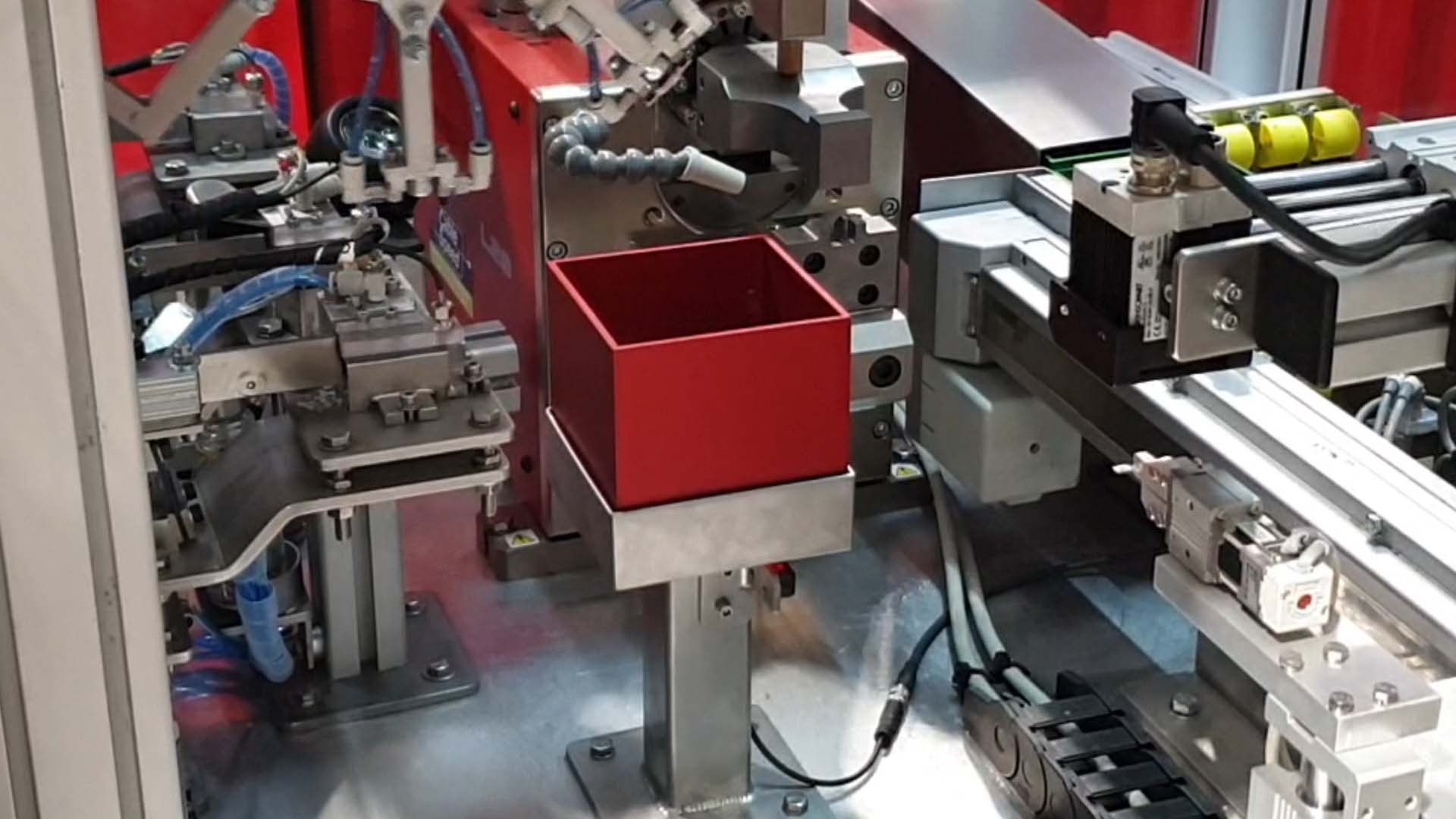

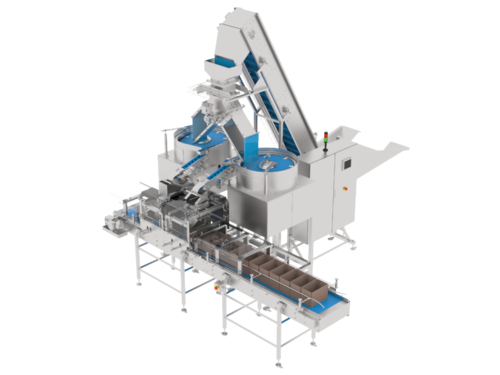

Vision systems can be deployed throughout your production line. Used early, they can help remove incorrect parts before they are consumed within a completed assembly. Towards the end of your production line they ensure your products meet your minimum requirements, ensuring no customer complaints.

From simple vision systems doing basic geometry or colour checks to ultra high pixel density camera recognition systems, Podmores work worth with you and recommend a suitable system to meet your quality control requirements.

In addition, we can integrate the vision system into a new Podmores solution, or your existing system.

- Automatic quality control.

- Ensure the highest quality of your product(s).

- Quick change vision programs for different product formats.

- Compact design fits into existing production lines or new lines easily.

- Hygienic options available, including vision systems for full washdown environments.

Integrated lighting

for maximum

repeatability

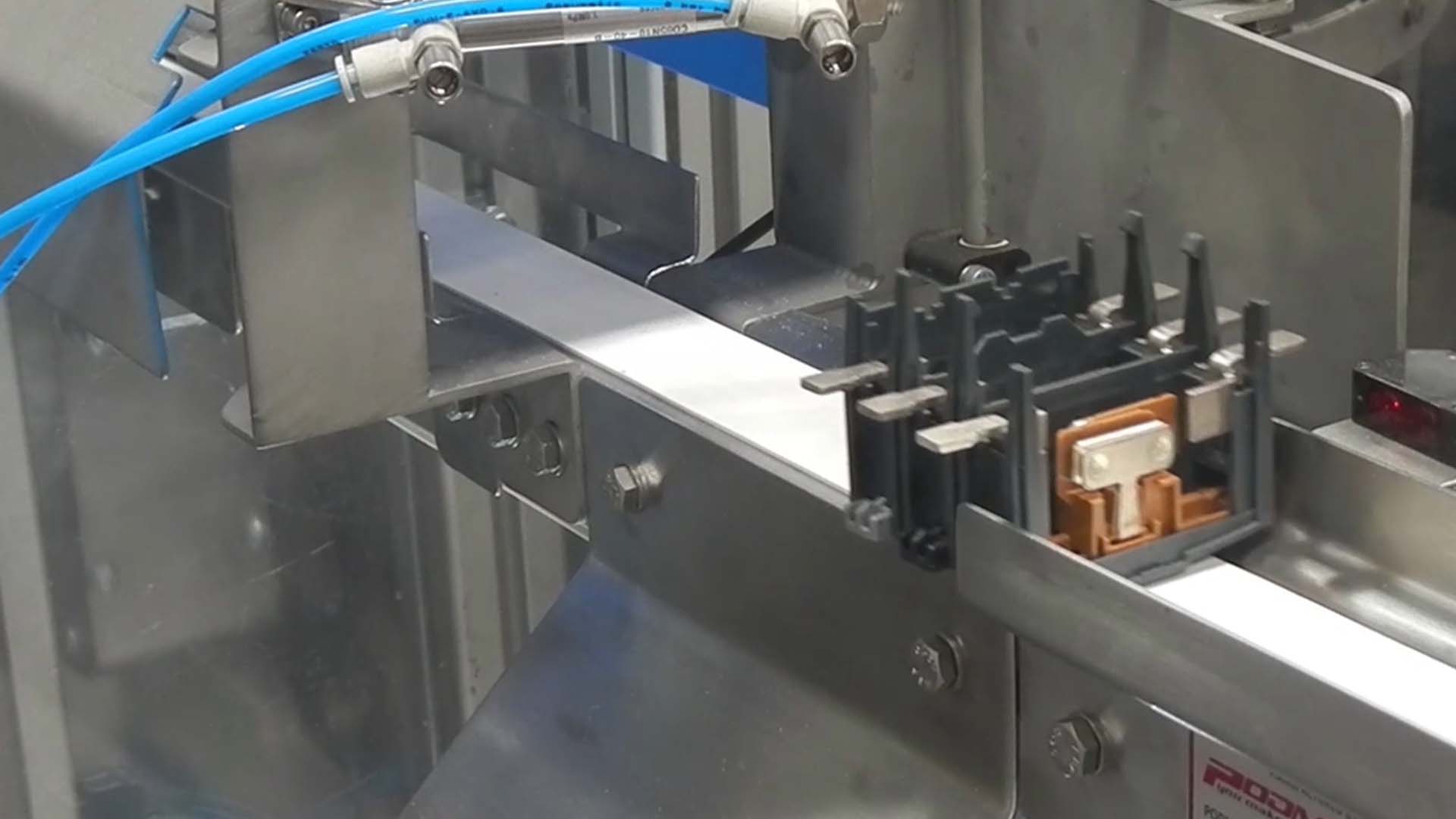

Pneumatic reject station

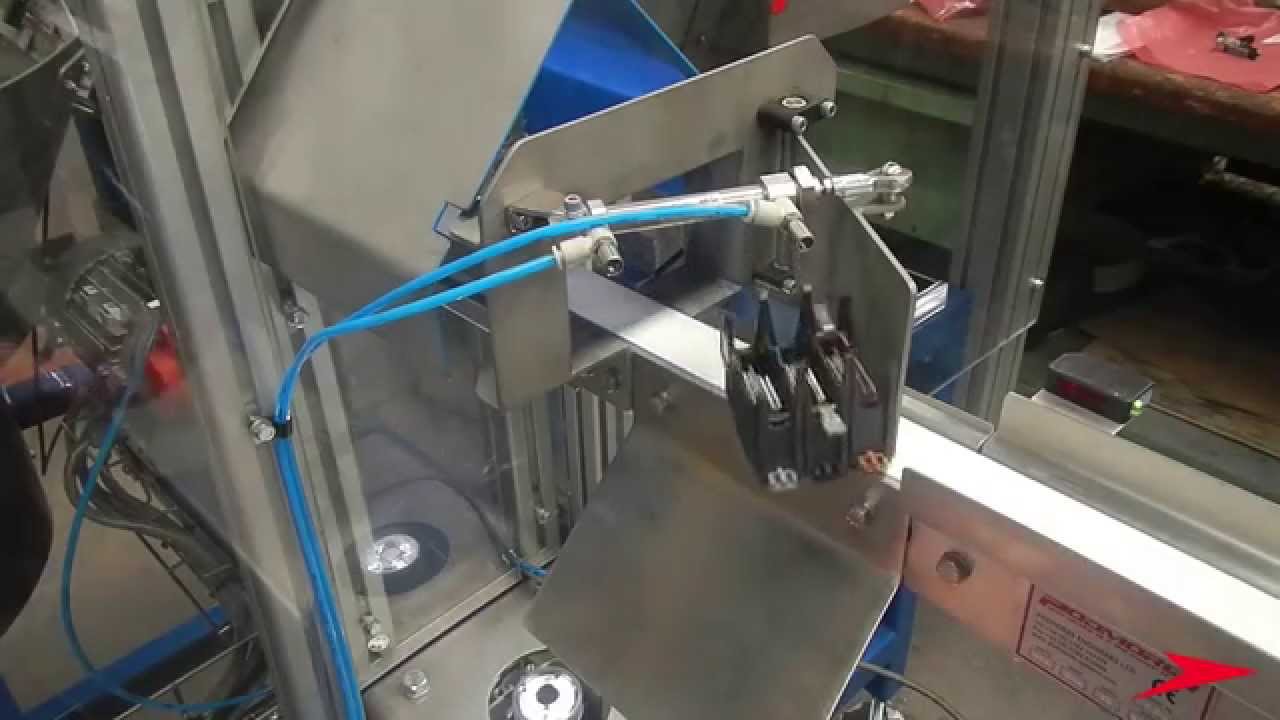

Use Podmores'

range of infeed

solutions to

complement your

vision system

Proven Technology

Podmores Vision Systems are found in factories all over the world, from small businesses to household name companies. Podmores Vision Systems quality check everything from bottles, electrical assemblies, crackers, sausages and much more, and are trusted in critical production line processes. Their durable design means almost no downtime.

Optimised

Auto adjusting vision inspections keep the vision system flexible for variations throughout the day, whether it’s subtle acceptable changes to your product or fluctuations in lighting in the vision system environment.

Gentle

If you need to capture data to validate the vision system’s data we can work with you to deploy a system capable of storing every image ever taken, or simply the ‘no good’ images so that you can investigate non-conformance and allow your engineers to work on improving product quality earlier in your production process.

Fill and forget

Our expertise with Storage & Infeed Systems allows us to deliver a solution no matter how much product you want to hold and how little you want to have to top the system up. Podmores can help you deploy storage solutions that keep your operatives free for other tasks around your factory.

Want to find out more?

Controllers

Spacing

Output

Hygienic Design

ATEX

Get in touch

Contact Us

ADDRESS

Podmores (Engineers) Ltd

Unit H Great Fenton Business Park, Grove Road, Stoke, Staffordshire,

ST4 4LZ, UK

Solving automation problems since 1930