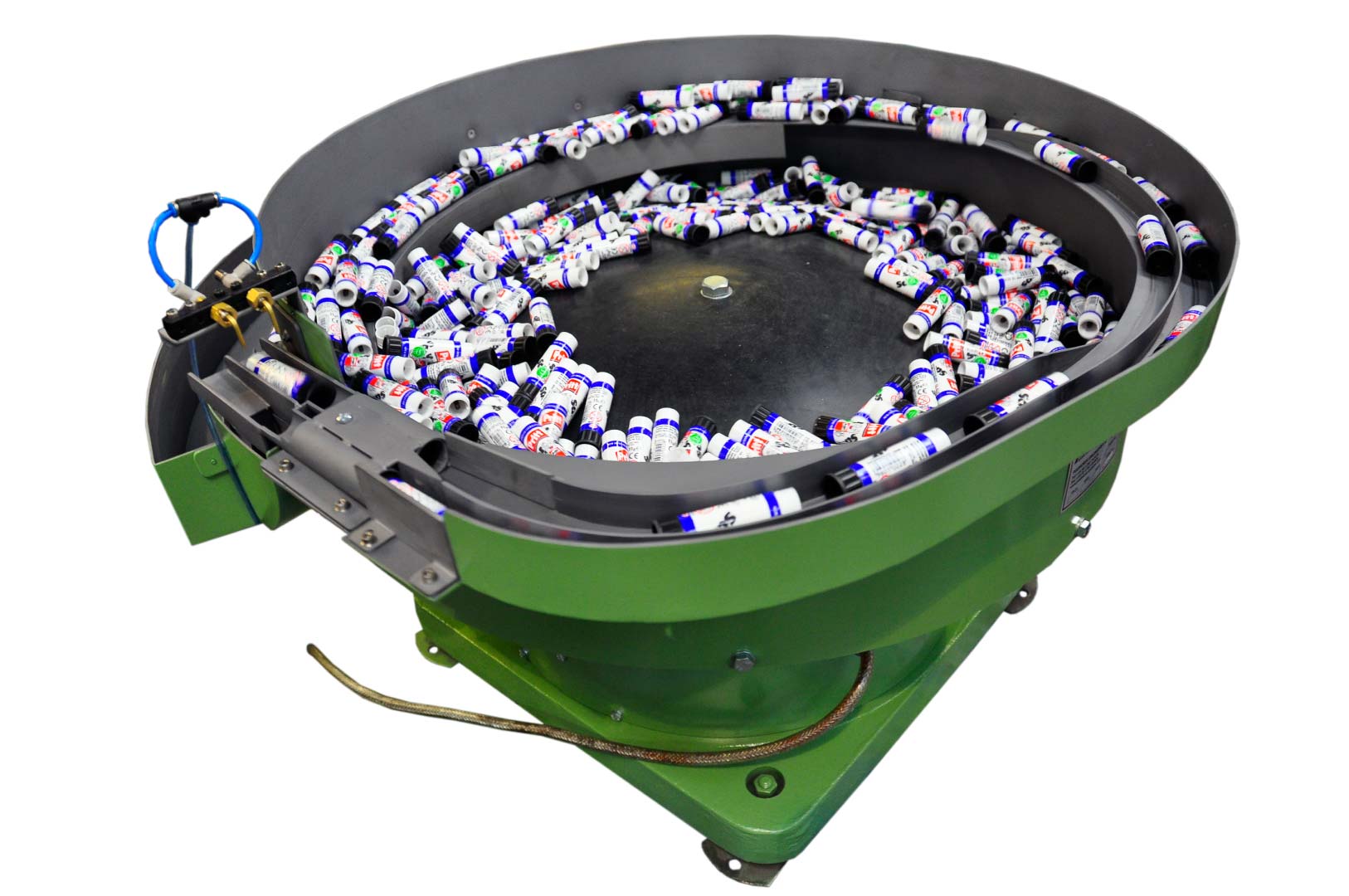

Vibratory bowl feeders can sort, orientate and filter your product. They are excellent at turning a box of product into an oriented stream for production or packaging lines.

| Frequency | 50Hz, 60Hz |

|---|---|

| IP Rating | IP00, IP20, IP54, IP65, IP66 |

| Materials | Aluminium, FDA Approved Plastics, FDA Rubber Lined, Mild Steel, Plastics, Rubber Lined, SS304, SS316L |

| Voltage | 110V, 230V, 415V |

Share

Learn more

Videos

Vibratory Bowl Feeders

Bring order from chaos

The most reliable established and robust Bowl Feeders available today. Podmores can orientate and feed your products gently while at the same time guaranteeing a consistent and accurate flow of products into your production machinery.

Accurate Feeding

Custom tooled Bowl Feeders allow consistent and accurate part feeding.

Variable Speed

Wide adjustment range with ability to lock off settings to prevent unauthorised access.

Infeed Solutions

Podmores offer a wide range of bulk storage infeed solutions to reduce operator refill times.

Reliable

Podmores offer an industry leading reliable design proven for 24/7/365 operation in critical process conditions.

Low Noise Level

The emission sound pressure level of our standard Bowl Feeders is below 65 dB(A) at 1m distance, without product (Lpa re. 20µPa).

Low Running Cost

A basic Bowl Feeder costs as little as £0.03 per hour in operation.

Easy to clean

No moving parts and our hygienic design mean an easy to clean machine suitable for raw food contact.

Customised Solution

Podmores offer a customised solution to your materials handling needs.

Want to find out more?

Applications

- Almost any component/product

- Aerospace components

- Automotive components

- Bottles

- Caps

- Confectionary

- Crisps/chips

- Dairy

- Ecig

- Electrical components

- Food

- Lids

- Medical items

- Military

- Nutritional products

- Pharmaceutical products

- Plastic parts

- Primary packed products

- Seafood

- Snack Foods

- And more

Key benefits

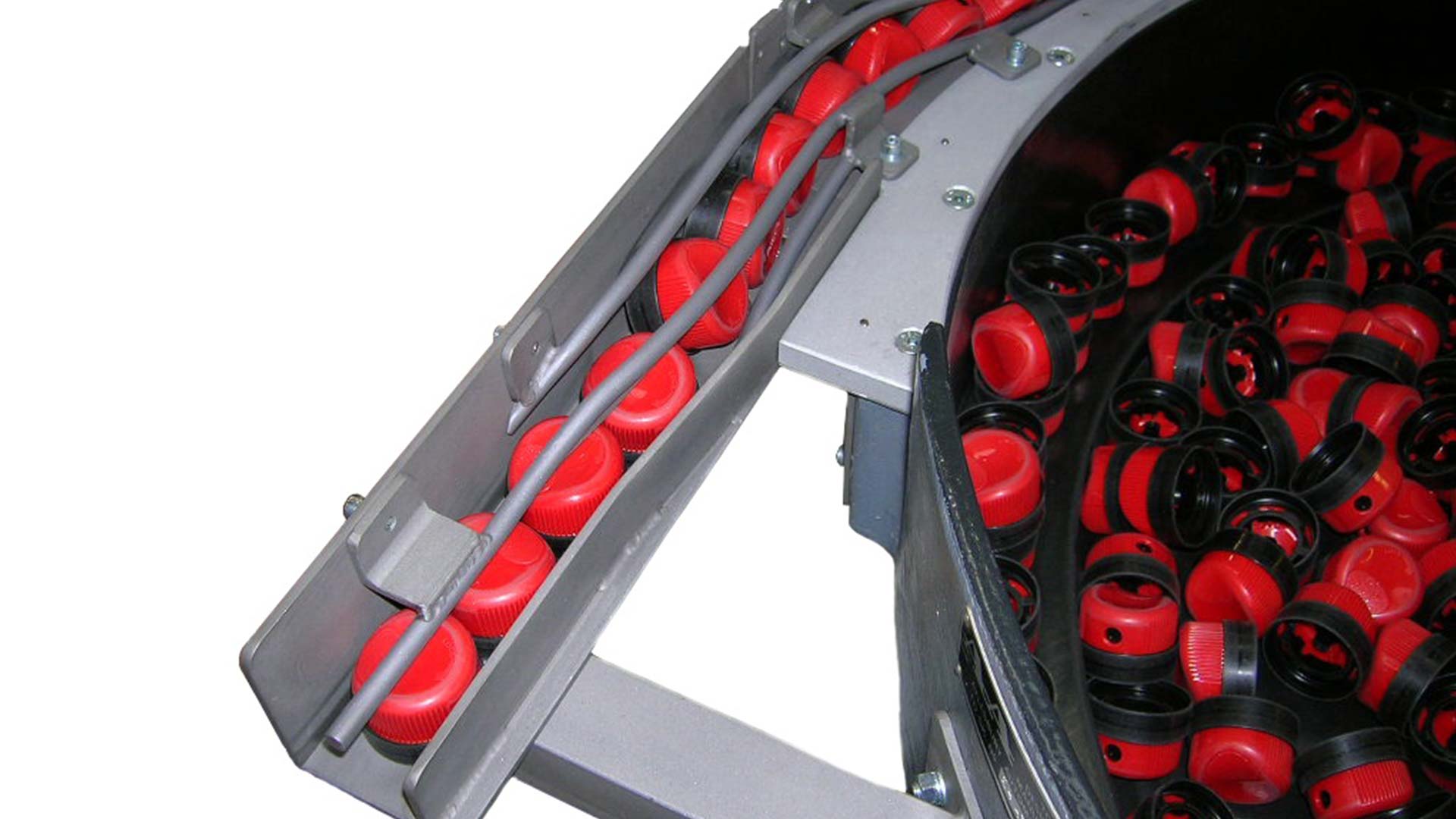

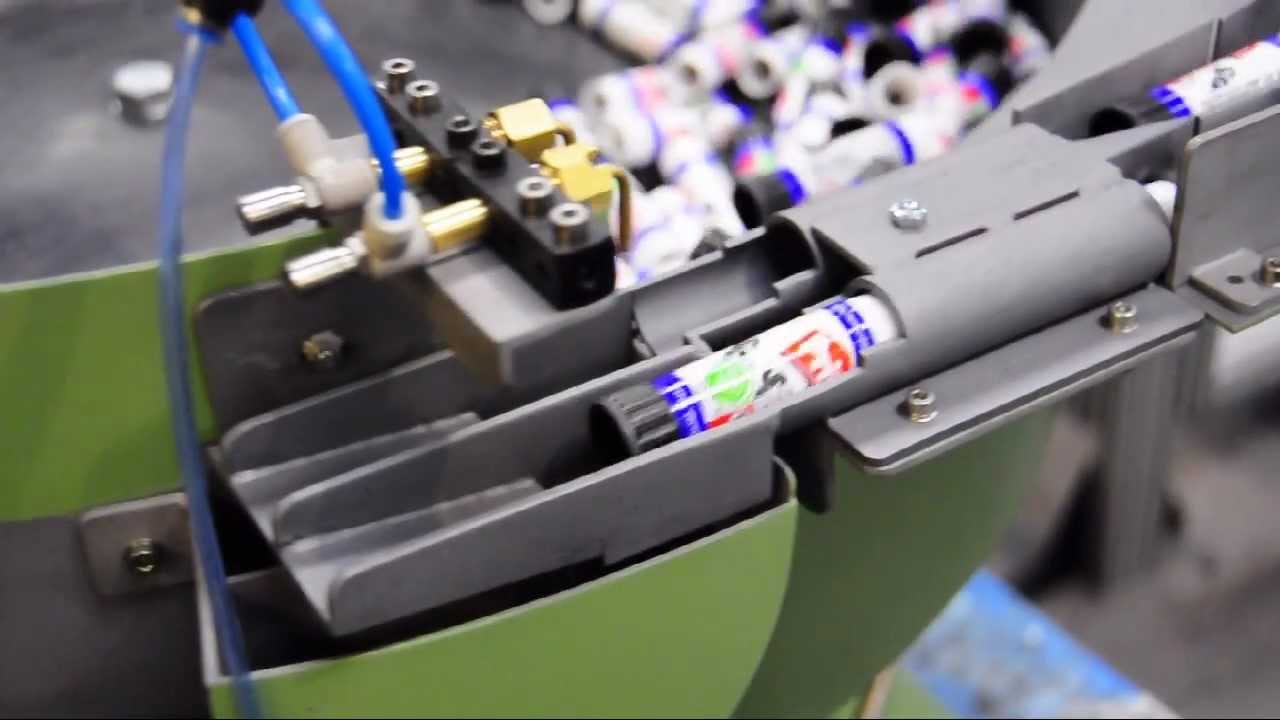

Vibratory Bowl Feeders are the most common industrial solution to feed sorted orientated parts to downstream machinery/processes. They use a powerful but gently vibration to move your products around the Bowl and then a range of tooling is used to only select components in the orientation you require.

Podmores are well known for providing customised solutions to parts handling & orientation problems. We provide a wide range of vibratory bowl feeder drive bases together with un-tooled or specifically tailor-made bowl tops covers almost every industry. Special outlets and escapement mechanisms allow even the most challenging components to be orientated and delivered at the right rate and in the correct orientation to meet your requirements.

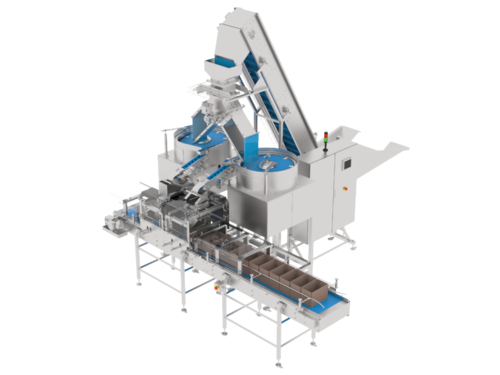

Vibratory bowl feeders can be supplied as standalone units, or be incorporated into packaging or automated systems. Bowl tops can be fabricated from stainless steel, mild steel, aluminium or plastics (including FDA approved) with widths: 100mm-1,500mm diameter and the internal tracks can be left in the raw material finish or lined/coated with a wide variety of materials.

- Vary speeds easily and simply.

- Creates even and consistent lanes of product.

- Interchangeable laning decks allow for quick product format changeover and future proof the machine for new products.

- Constant feed rate that doesn't adjust over time.

- Compact design fits into existing production lines or new lines easily.

- Hygienic design and stainless steel contact materials.

- Optional hopper for product storage.

- Optional screening to remove small undersize product.

- Static or mobile versions available.

Powerful drive

units

Customised tooling

to suit any product

Outfeed transfers

available

A range of materials

are available to

suit your needs

Proven Technology

Podmores Bowl Feeders are found in factories all over the world, from small businesses to household name companies. Podmores Bowl Feeders provide the critical infeed solution required for almost any production line. The durable design means almost no downtime

Gentle

Podmores vibratory Bowl Feeders offer an incredibly gentle solution to your parts handling and infeed needs. Since 1930 we’ve handled almost every component imaginable, including products as gentle as live rounds of ammunition at high throughputs. This experience and our testing/demonstration facilities allow us to prove to you that our solutions are the best option for our orientation and sorting needs.

DIFFERENT DESIGNS TO SUIT YOUR NEEDS

Podmores offer 20 sizes of Bowl Feeder to suit your specific needs. Our flexible range can be configured to meet your exact product handling requirements.

Fill and forget

Our expertise with Storage & Infeed Systems allows us to deliver a solution no matter how much product you want to hold and how little you want to have to top the system up. Podmores can help you deploy storage solutions that keep your operatives free for other tasks around your factory.

Want to find out more?

Controllers

Orientation

Output

Laned Output

Hygienic Design

ATEX

Related products

Get in touch

Contact Us

ADDRESS

Podmores (Engineers) Ltd

Unit H Great Fenton Business Park, Grove Road, Stoke, Staffordshire,

ST4 4LZ, UK

Solving automation problems since 1930