Elevate with a gentle (high frequency) or powerful (low frequency) construction. Extended product retention for curing with optional heating/cooling. Space saving footprint and gentle, hygienic handling.

| Frequency | 50Hz, 60Hz |

|---|---|

| IP Rating | IP54, IP65, IP66, IP67, IP68, IP69K |

| Materials | FDA Approved Plastics, FDA Rubber Lined, Mild Steel, Plastics, Rubber Lined, SS304, SS316L |

| Voltage | 110V, 230V, 415V |

Share

Learn more

Videos

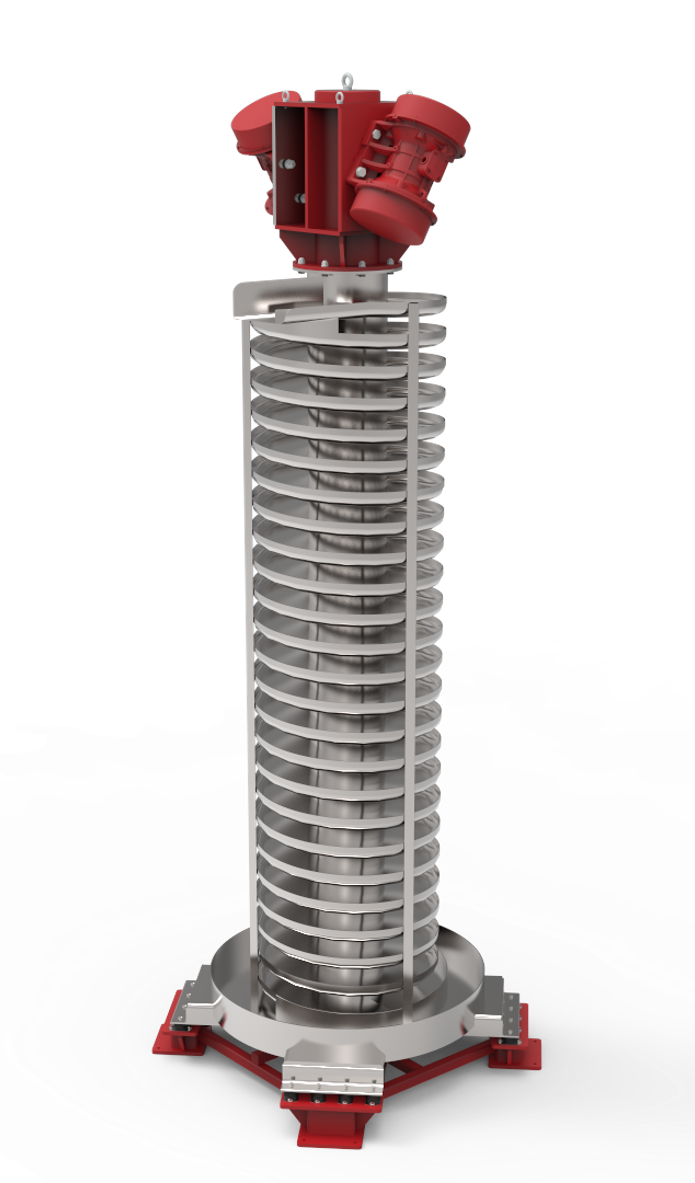

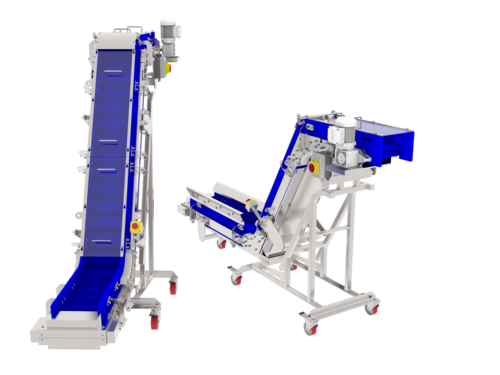

Spiral Elevators

Compact and gentle elevation

Elevate your product in the smallest footprint, straight upwards to where you need it to go.

Straight up

Elevate vertically without the need for extra space for inclines.

Variable Speed

Wide adjustment range with ability to lock off settings to prevent unauthorised access.

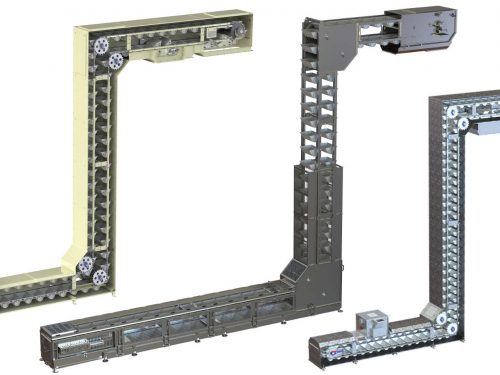

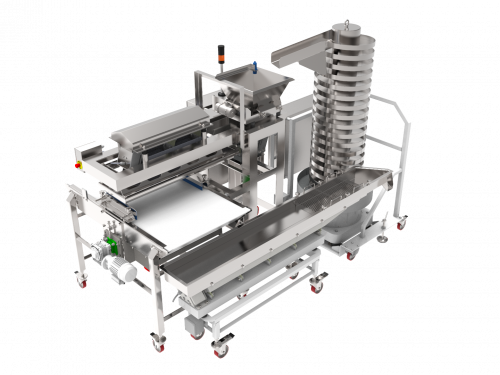

Infeed Solutions

Podmores offer a wide range of bulk storage infeed solutions to reduce operator refill times.

Reliable

Podmores offer an industry leading reliable design proven for 24/7/365 operation in critical process conditions.

Low Noise Level

The emission sound pressure level of all our Spiral Elevators is below 70 dB(A) at 1m distance, without product (Lpa re. 20µPa).

Low Running Cost

A basic Spiral costs as little as £0.20 per hour in operation.

Easy to clean

No moving parts and our hygienic design mean an easy to clean machine suitable for raw food contact.

Customised Solution

Podmores offer a customised solution to your materials handling needs.

Want to find out more?

Applications

- Almost any component/product

- Candy pieces

- Confectionary

- Dough

- Dry, flowable ingredients

- Enrobed products

- Fish

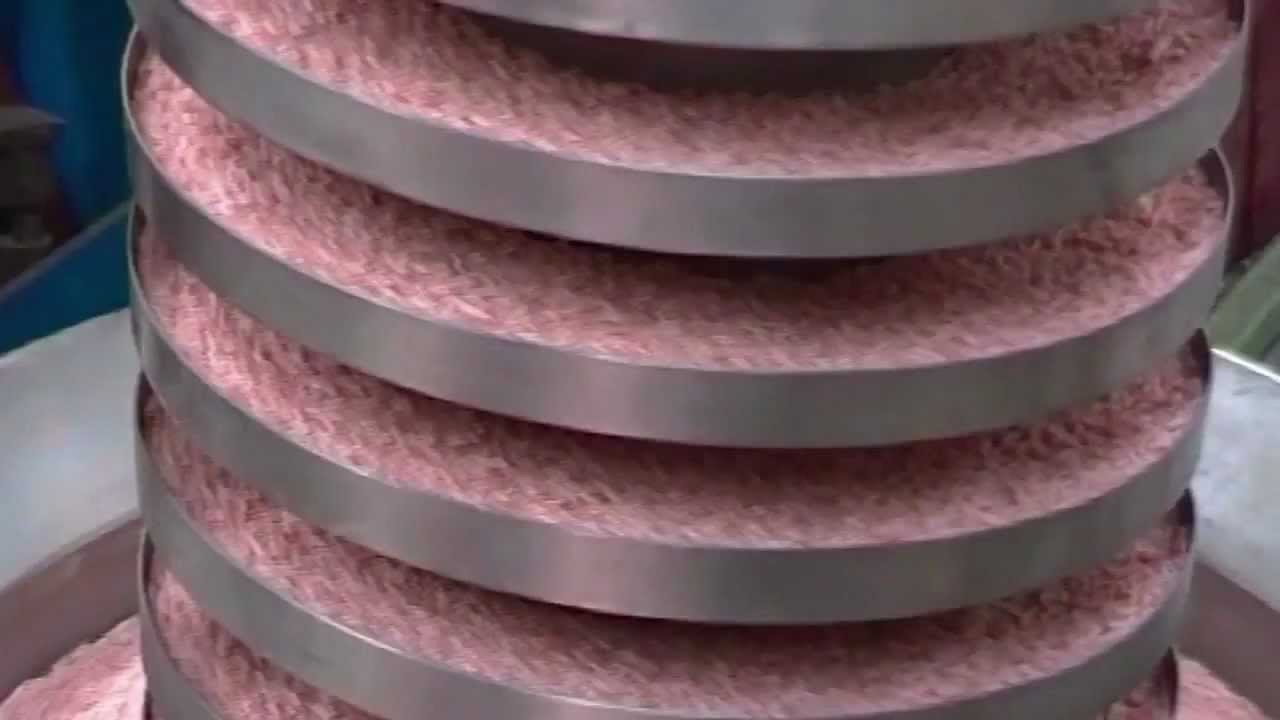

- Meat

- Nuts

- Rice

- Seafood

- And more

Key benefits

Elevate with a gentle (high frequency) or powerful (low frequency) construction. Extended product retention for curing with optional heating/cooling. Space saving footprint and gentle, hygienic handling.

Using the smallest of footprints the spiral elevator will lift products and provide a controlled feed to the next process equipment.

- Minimal footprint with maximum elevation

- Gentle but powerful vibration

- Compact design fits into existing production lines or new lines easily.

- Hygienic design and stainless steel contact materials.

- Static or mobile versions available

Tried and tested

Podmores drive

unit powers the

Spiral

Product feeds up

the Spiral Elevator

Outlets can be

customised to suit

your requirements

Proven Technology

Podmores Spiral Elevators are found in factories all over the world, from small businesses to household name companies. Podmores Spiral Elevators provide handle dough offcuts, chocolates, cake toppings, recycled tyres and much more, and are trusted in critical production line processes. Their durable design means almost no downtime.

Want to find out more?

Controllers

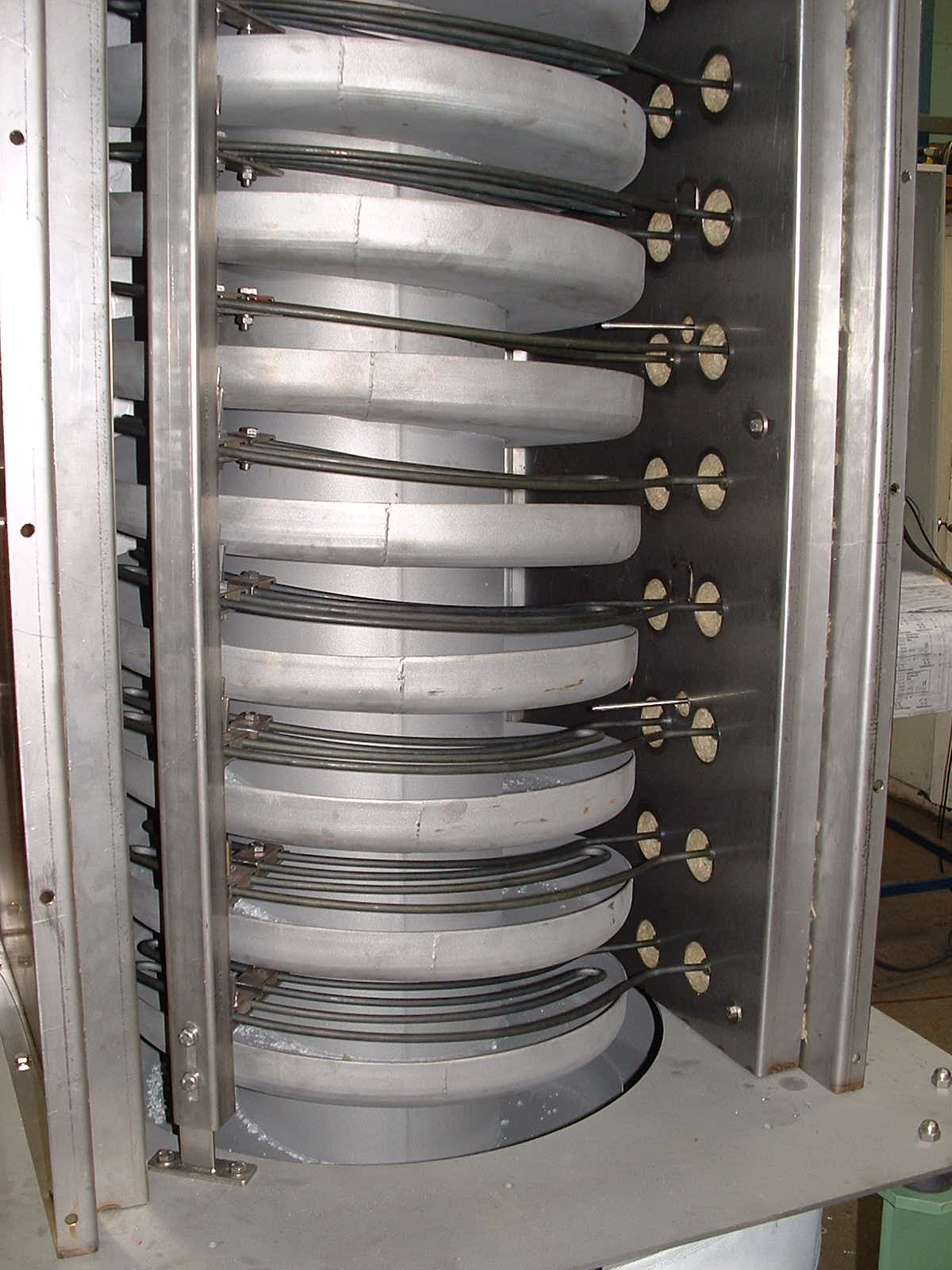

Heating/Cooling

Output

Hygienic Design

ATEX

Related products

Get in touch

Contact Us

ADDRESS

Podmores (Engineers) Ltd

Unit H Great Fenton Business Park, Grove Road, Stoke, Staffordshire,

ST4 4LZ, UK

Solving automation problems since 1930