Gently sorting & orientation of tubular and cylindrical products, or elevation of small parts.

Share

Learn more

Videos

Sprinkling, Spreading & Depositing

Quiet and gentle product sorting

One of the gentlest infeed options available, step feeders are perfect for damage free infeeds for delicate products

Gentle

Reduce damage by only moving your products short distances in a Step Feeder.

Variable Speed

Wide adjustment range with ability to lock off settings to prevent unauthorised access.

Infeed Solutions

Podmores offer a wide range of bulk storage infeed solutions to reduce operator refill times.

Reliable

Podmores offer an industry leading reliable design proven for 24/7/365 operation in critical process conditions.

Low Noise Level

The emission sound pressure level of our standard Step Feeder is below 65 dB(A) at 1m distance, without product (Lpa re. 20µPa).

Low Running Cost

A basic Step Feeder costs as little as £0.20 per hour in operation.

Safe

No nip/trap points by design.

Customised Solution

Podmores offer a customised solution to your materials handling needs.

Want to find out more?

Applications

- Cylindrical products

- Munitions

- Round bars

- Small parts

- And more

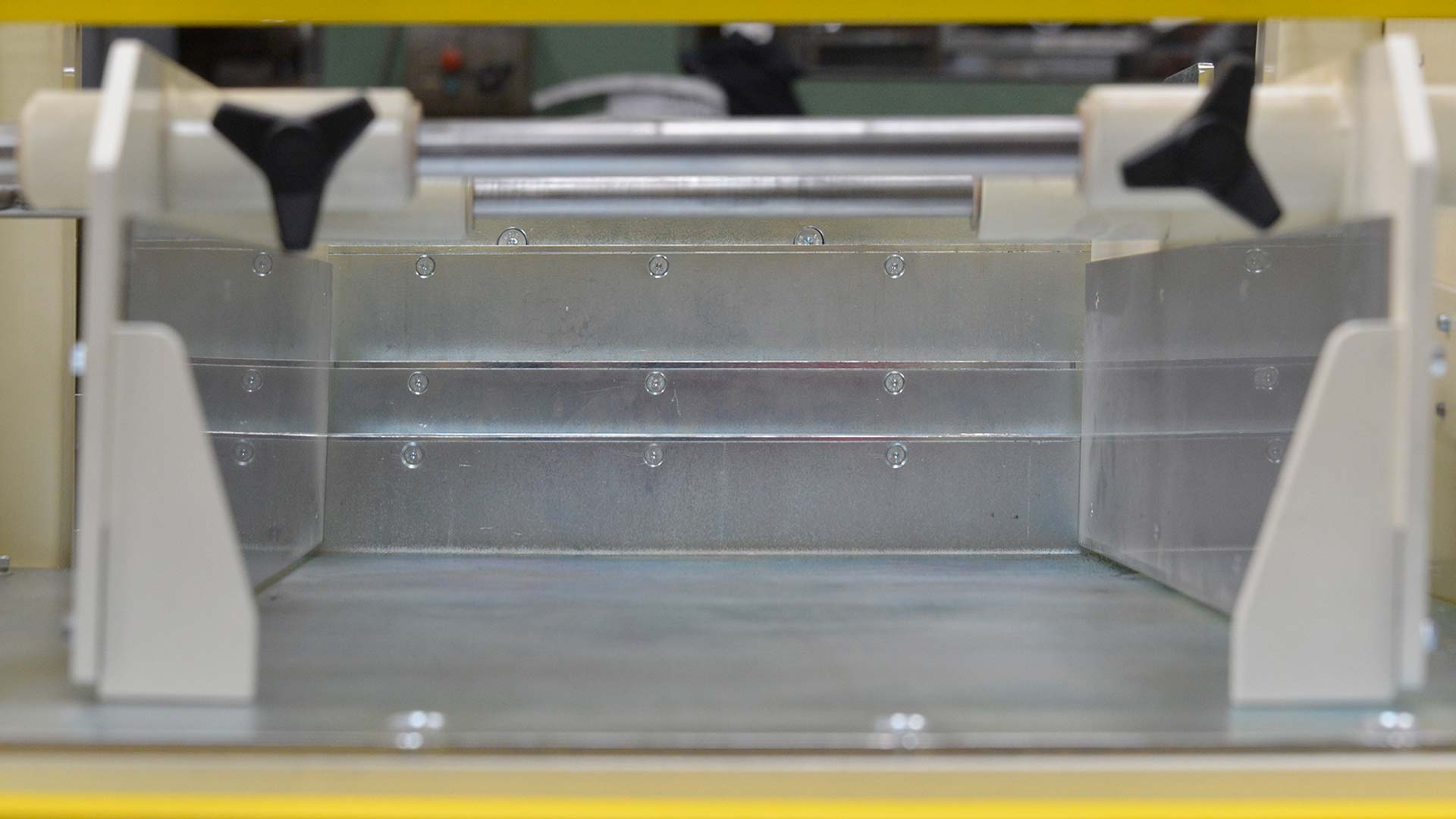

Key benefits

Podmores step feeders allow you to easily and gently orientate and raise products over short to medium heights. Step feeders work by raising ‘steps’ which create an upwards waterfall effect. There is very little damage to product being handled as the product typically only moves a few millimeters at a time. Because of their gentle nature, step feeders are particularly suited to military applications and generally to industries with delicate products or gentle handling requirements.

- Incredibly gentle product handling.

- Creates accurately sorted products for your next process.

- Constant feed rate that doesn't adjust over time.

- Compact design fits into existing production lines or new lines easily.

- Optional hopper for product storage.

- Static or mobile versions available.

Hopper feeder to store

product, freeing up

operators for other tasks

Long elevation

version

Short elevation

for sorting and

delivering round

or tubular products

Adjustable side

guides for products

of differing lengths

Proven Technology

Podmores Step Feeders are found in factories all over the world, from small businesses to household name companies. Podmores Step Feeders provide the blank bars for machining, rebar for automated robotic insertion, bullet tips for final processing and much more, and are trusted in critical production line processes. Their durable design means almost no downtime.

Gentle

Deployed in applications requiring absolutely no product damage and trusted to deliver consistently delicate product handling.

Fill and forget

Our expertise with Storage & Infeed Systems allows us to deliver a solution no matter how much product you want to hold and how little you want to have to top the system up. Podmores can help you deploy storage solutions that keep your operatives free for other tasks around your factory.

Want to find out more?

Controllers

Spacing

Output

Hygienic Design

ATEX

Get in touch

Contact Us

ADDRESS

Podmores (Engineers) Ltd

Unit H Great Fenton Business Park, Grove Road, Stoke, Staffordshire,

ST4 4LZ, UK

Solving automation problems since 1930