Quickly and efficiently sort your product without slowing production. They can be used to separate good product from broken or over-size product, rapidly providing in-line quality control, or to separate different sizes of product coming off one production line.

| Frequency | 50Hz, 60Hz |

|---|---|

| IP Rating | IP54, IP65, IP66 |

| Materials | Aluminium, FDA Approved Plastics, FDA Rubber Lined, Mild Steel, Plastics, Rubber Lined, SS304, SS316L |

| Voltage | 110V, 230V, 415V |

Share

Learn more

Videos

Sprinkling, Spreading & Depositing

Rapid inline quality control & sorting

Remove oversize (large), undersize (small) or incorrect parts from your product stream or simply grade your product by its physical size.

Accurate grading

Remove large or small parts, or separate your product by size, easily and accurately

Variable Speed

Wide adjustment range with ability to lock off settings to prevent unauthorised access.

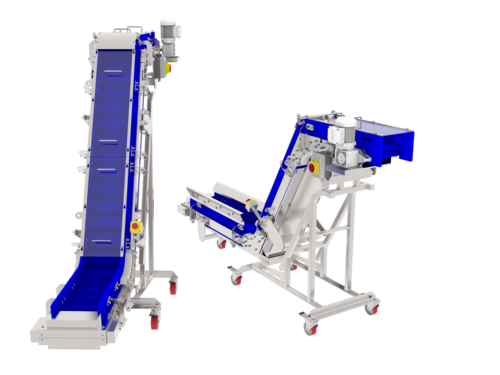

Infeed Solutions

Podmores offer a wide range of bulk storage infeed solutions to reduce operator refill times.

Reliable

Podmores offer an industry leading reliable design proven for 24/7/365 operation in critical process conditions.

Low Noise Level

The emission sound pressure level of our standard screen feeders is below 70 dB(A) at 1m distance, without product (Lpa re. 20µPa).

Low Running Cost

A basic Vibratory Screen costs as little as £0.20 per hour in operation.

Easy to clean

No moving parts and our hygienic design mean an easy to clean machine suitable for raw food contact.

Customised Solution

Podmores offer a customised solution to your materials handling needs.

Want to find out more?

Applications

- Almost any component/product

- Candy Pieces

- Cereals

- Chewing gum pillows

- Confectionary

- Dry, flowable ingredients

- Fasteners & fixings

- Fruit (including raisins etc)

- IQF breaded meats

- Mints

- Nuts

- Powders

- Prawns

- Rice

- Tablets

- And more

Key benefits

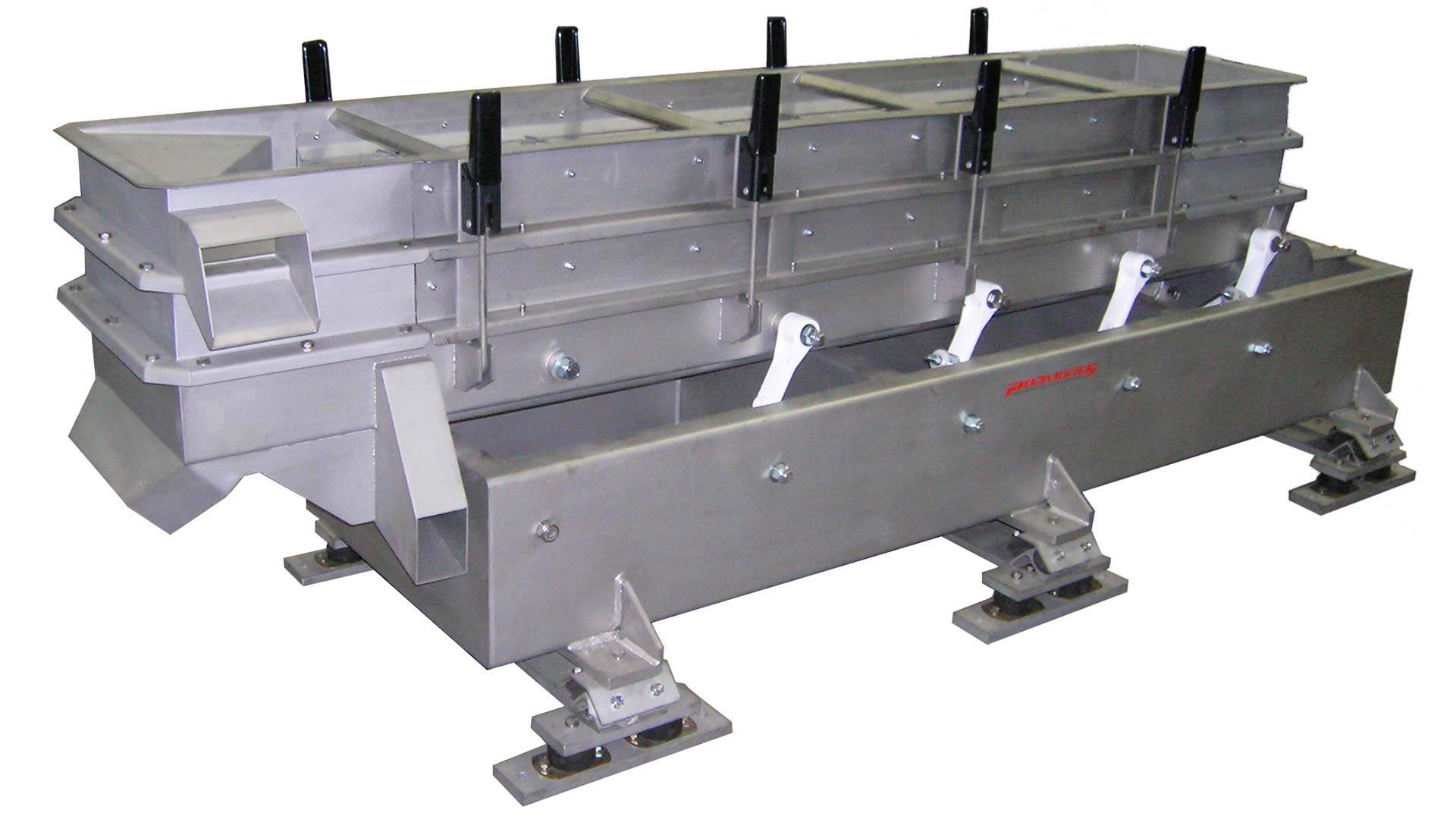

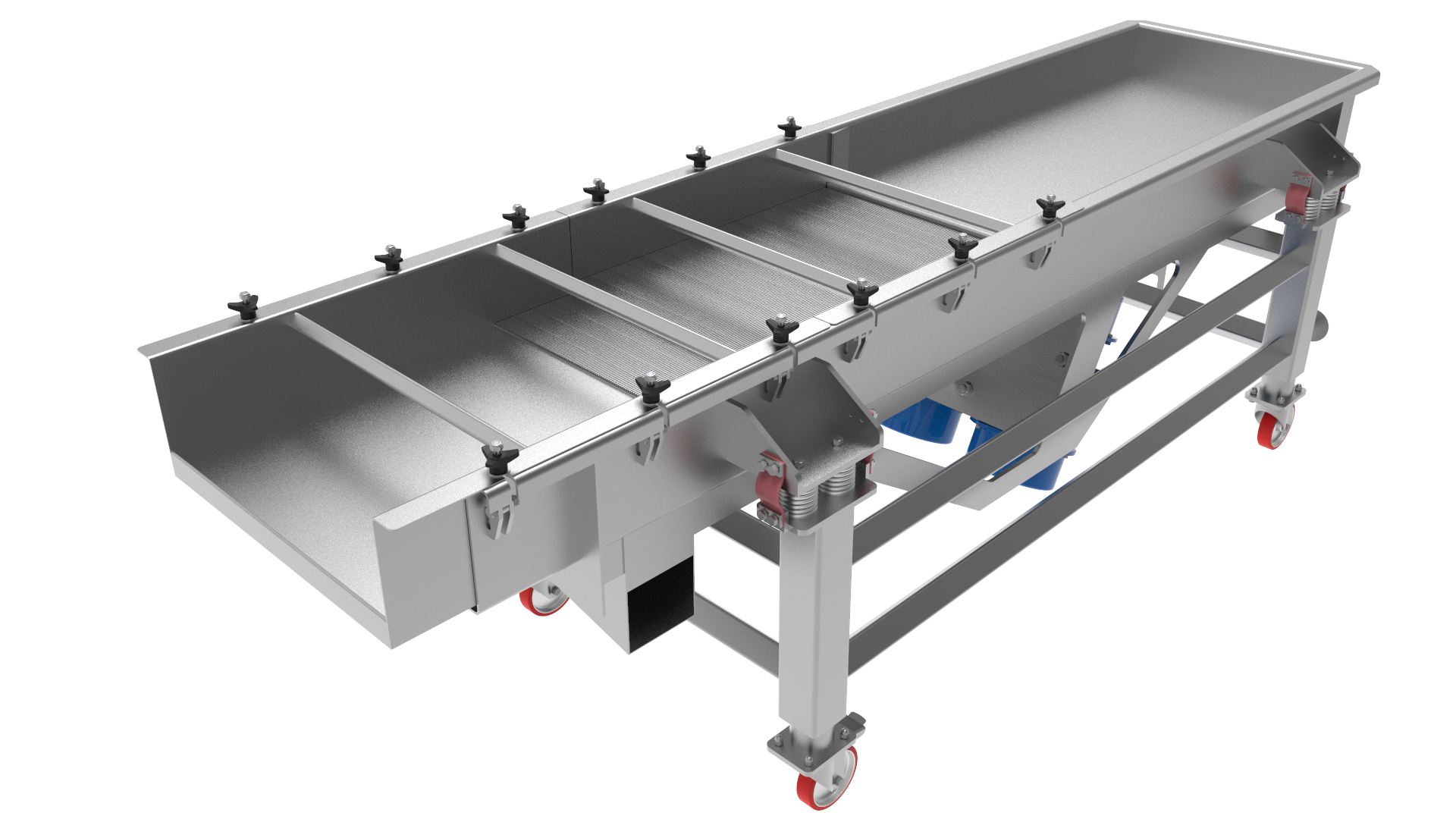

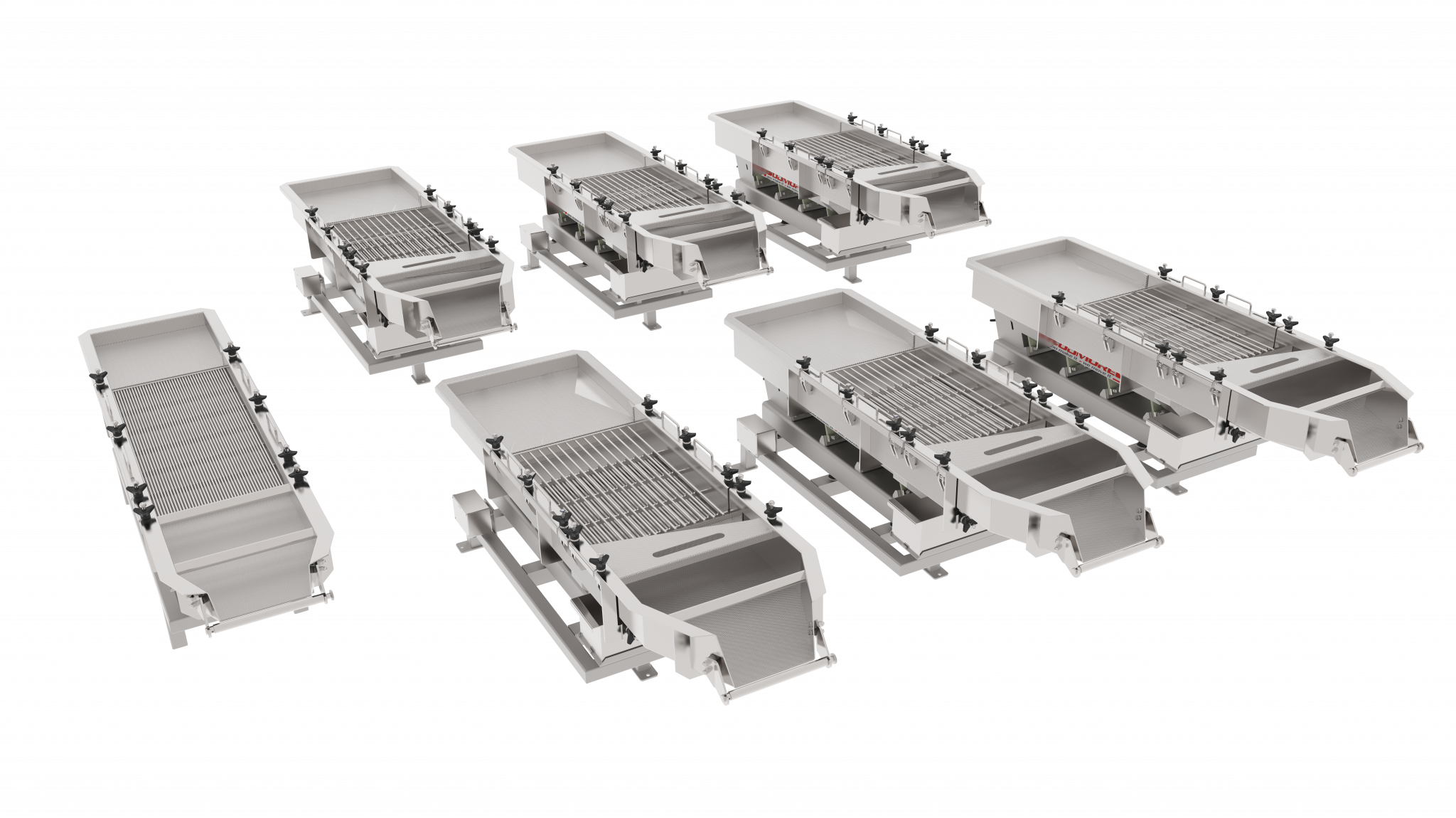

Podmores Vibratory Screens and Graders allow you to quickly and efficiently sort your product without slowing production.

They can be used to separate good product from broken or over-size product, rapidly providing in-line quality control, or to separate different sizes of product coming off one production line. Product separated from the product flow can be directed into bins or storage for reuse or recycling.

Using the same tried and tested machine set-up as our vibratory linear feeder range, Podmores screens and graders will keep your production lines running exactly as you need them to.

- Manufactured specifically for your product range & requirements

- Vary speeds easily and simply.

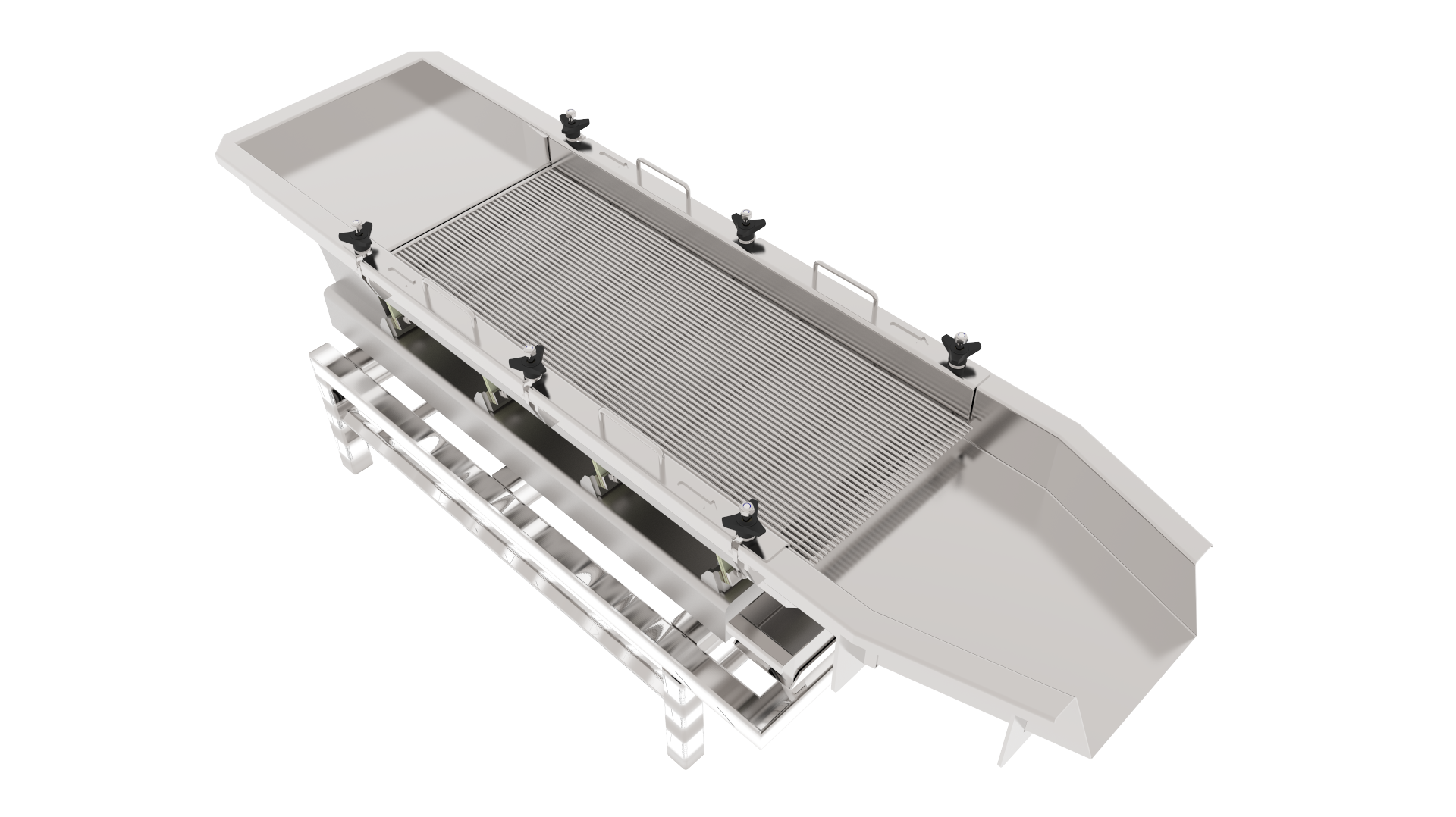

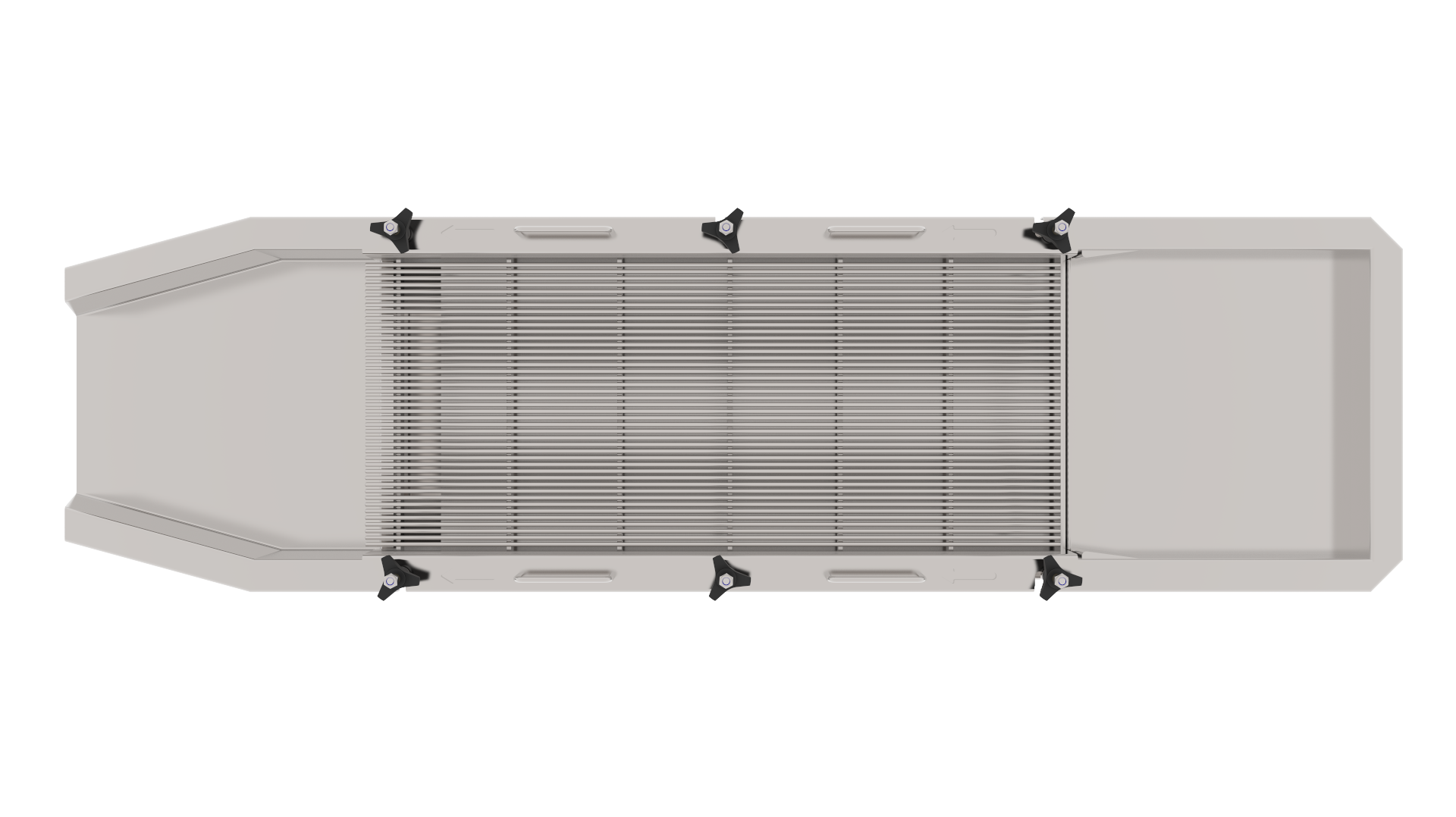

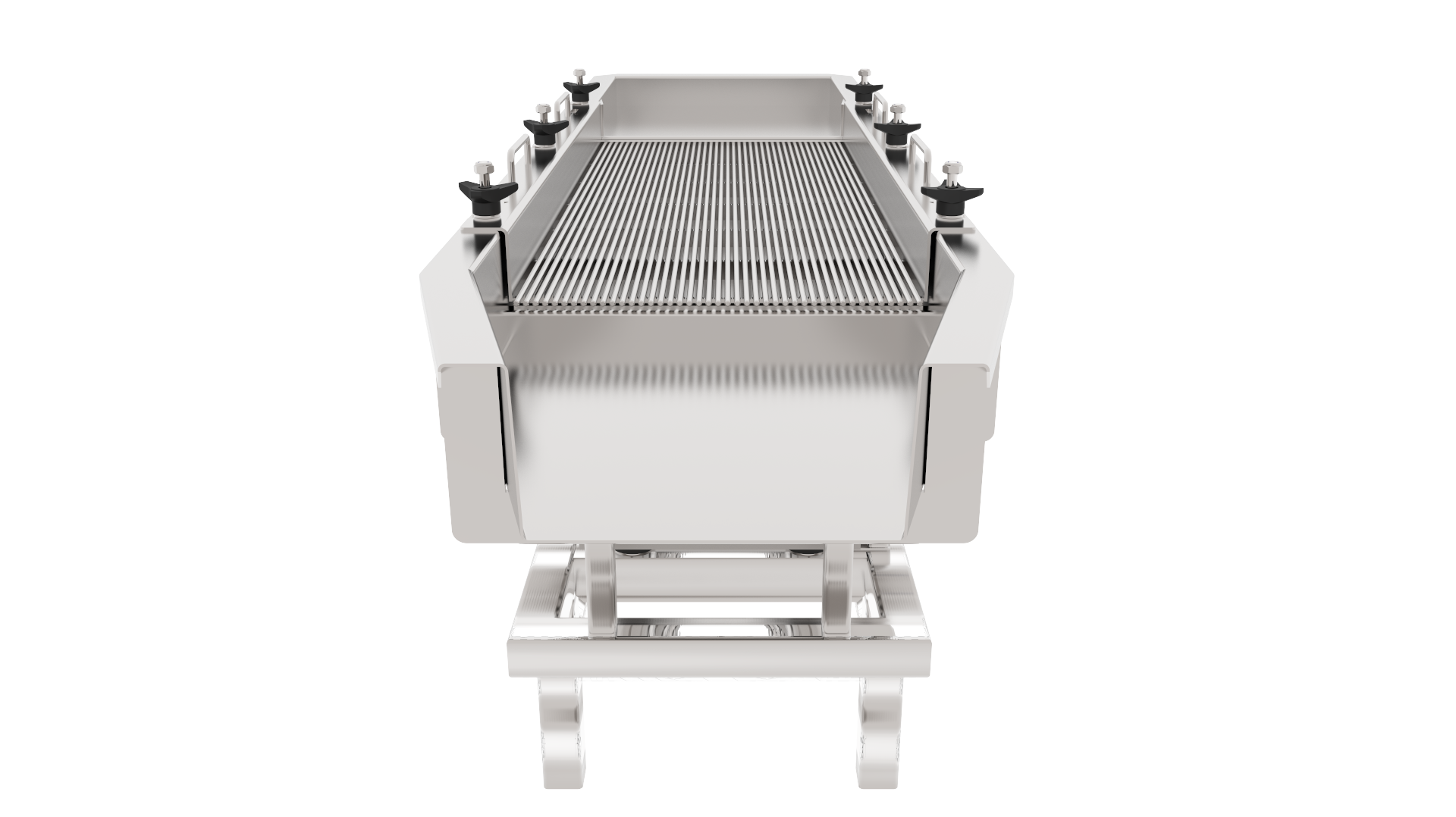

- Interchangeable screens and trays allow for quick product format changeover and future proof the machine for new products.

- Fast & accurage sorting

- Dust & particulate suppression available

- Constant feed rate that doesn't adjust over time.

- No moving parts

- Compact design fits into existing production lines or new lines easily.

- Hygienic design and stainless steel contact materials.

- Optional hopper for product storage.

- Optional screening to remove small undersize product.

- Static or mobile versions available.

Optional inlet and

outlet spigots for

dust tight connections

Optional lids and

inspection or

cleaning port

Oversize product

can exit left, right

or straight forwards

Undersize product

can exit left, right

or straight forwards

Good product

can exit left, right

or straight forwards

Tried and

tested feeder

drive unit

Proven Technology

Podmores Screen Feeders & Grading Feeders are found in factories all over the world, from small businesses to household name companies. Podmores Screen Feeders have handled almost every product, such as nuts, rice, fruit, confectionary, snack foods, provide the nuts, chocolates and much more, and are trusted in critical production line processes. Their durable design means almost no downtime.

Interchangeable

Podmores can manufacture your Grader with interchangeable trays allowing you to swap them easily and quickly for different products. This is perfect for production lines handling different products. Quick release clamps can be used to further speed up the changeover between different product formats.

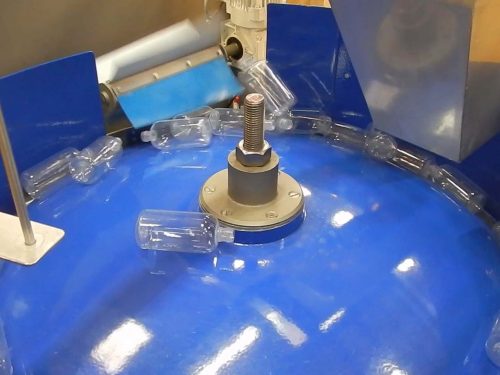

Flexible inlets & outlets

Choose from a wide variety of inlets to suit your requirements. From a simple open design to flexible material bellows to complicated choke arrangements, Podmores can manufacture the right inlet for your production line. Flexible inlets and outlets allow you to contain dust and particulates keeping the area around the machine clean and protecting operatives when working with harmful products.

Fill and forget

Our expertise with Storage & Infeed Systems allows us to deliver a solution no matter how much product you want to hold and how little you want to have to top the system up. Podmores can help you deploy storage solutions that keep your operatives free for other tasks around your factory.

Want to find out more?

ATEX

Hygienic Design

Dust tight

Controllers

Get in touch

Contact Us

ADDRESS

Podmores (Engineers) Ltd

Unit H Great Fenton Business Park, Grove Road, Stoke, Staffordshire,

ST4 4LZ, UK

Solving automation problems since 1930