Gently, quickly and safety elevate your product in a food grade belt elevator. We can supply food and non-food grade flighted belt elevators using a range of materials including thermoplastic-polyurethane (TPU), Thermoplastic-Elastomer (TPE), Polyethylene (PE), Polypropylene (PP) and Polyacetal (POM). The flights on the belt push your product along and when the belt inclines they keep pushing it up to the top where it can be deposited into the next machine/process.

| Frequency | 50Hz, 60Hz |

|---|---|

| IP Rating | IP54, IP65, IP66, IP67, IP68, IP69K |

| Materials | Aluminium, FDA Approved Plastics, FDA Rubber Lined, Mild Steel, Plastics, SS304, SS316L |

| Voltage | 110V, 230V, 415V |

Share

Learn more

Gentle product elevation in a hygienic design

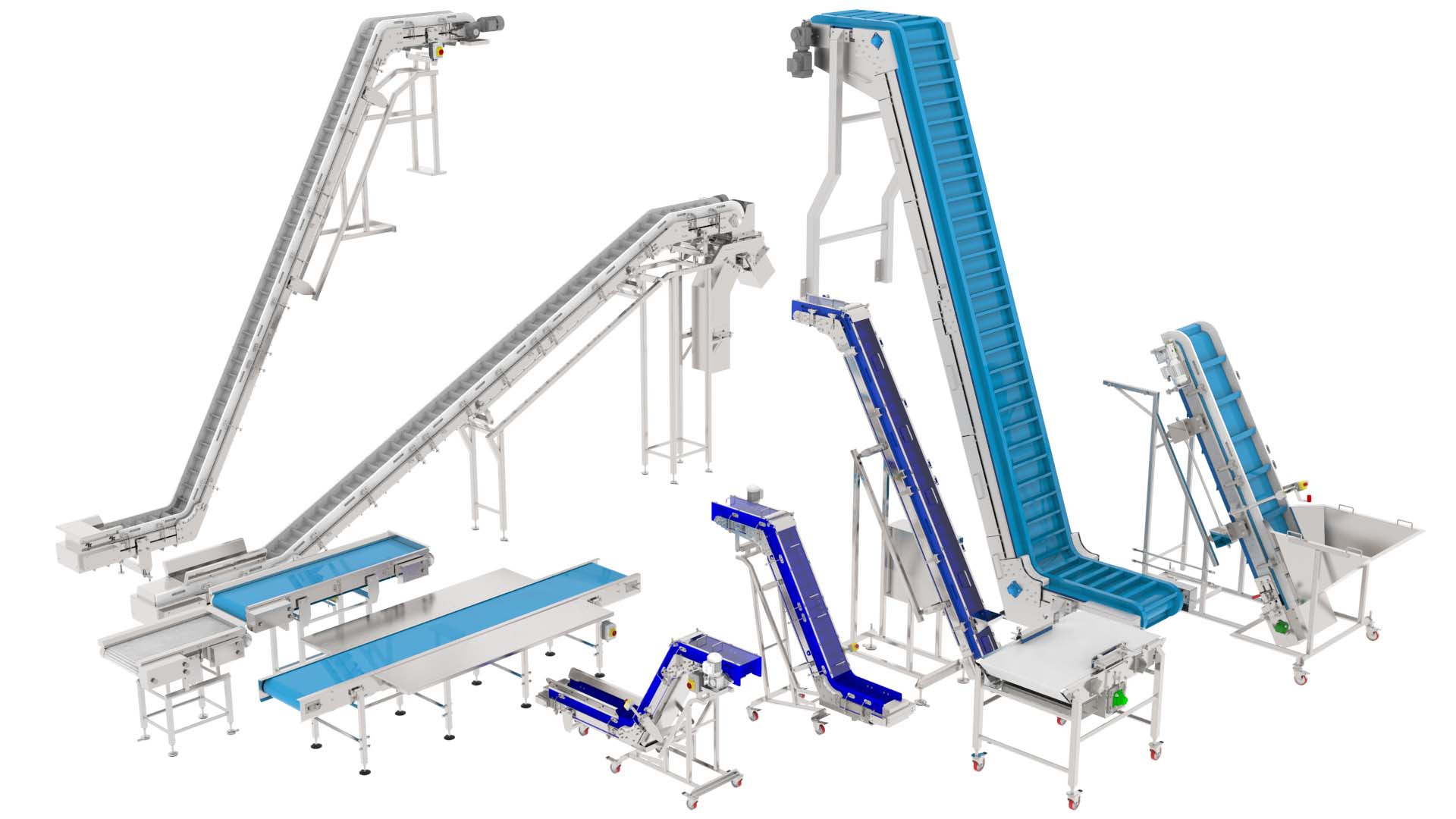

Various designs available to suit your specific needs.

Gentle handling

Belt Elevators provide a gentle elevation to your product.

Variable Speed

Wide adjustment range with ability to lock off settings to prevent unauthorised access.

Infeed Solutions

Podmores offer a wide range of bulk storage infeed solutions to reduce operator refill times.

Reliable

Podmores offer an industry leading reliable design proven for 24/7/365 operation in critical process conditions.

Low Noise Level

The emission sound pressure level of our standard Elevators is below 65 dB(A) at 1m distance, without product (Lpa re. 20µPa).

Low Running Cost

A basic Elevator costs as little as £0.04 per hour in operation.

Easy to clean

Hygienic design options mean an easy to clean machine suitable for raw food contact.

Customised Solution

Podmores offer a customised solution to your materials handling needs.

Want to find out more?

Applications

- Almost any component/product

- And more

- Dry, flowable ingredients

- Cereal

- Chocolate

- Cheese (including grated)

- Chewing gum

- Coffee

- Confectionary

- Fish

- Fruit

- Grains

- Inclusions & toppings

- Meat

- Nuts

- Pasta

- Pharmaceuticals

- Popcorn

- Powders

- Rice

- Seafood

- Seeds

- Snack Foods

- Tea

- Vegetables

Key benefits

Podmores Flighted Belt Elevators are perfect for elevating your products gently and quickly in a clean and safe machine. We use plastic belt and also various softer rubber belts which all meet food safety standards. The flights on the belt push your product along and when the belt inclines they keep pushing it up to the top where it can be deposited into the next part of your system.

Available in almost any size, Podmores can build a Flighted Belt Elevator to your exact specification.

Flighted Belt Elevators can be fitted with a hopper loader to make loading by hand easy and less time-consuming.

- Range of belt materials, including monolithic homogenous belts, rubber/TPU, fabric and plastic modular.

- Hygienic design available with fully stainless steel/FDA materials, and optional washdown features.

- Vary speeds easily and simply.

- Gentle product handling to elevate your product.

- Constant feed rate that doesn't adjust over time.

- Optional hopper for product storage.

- Static or mobile versions available.

Optional hopper

for product

storage

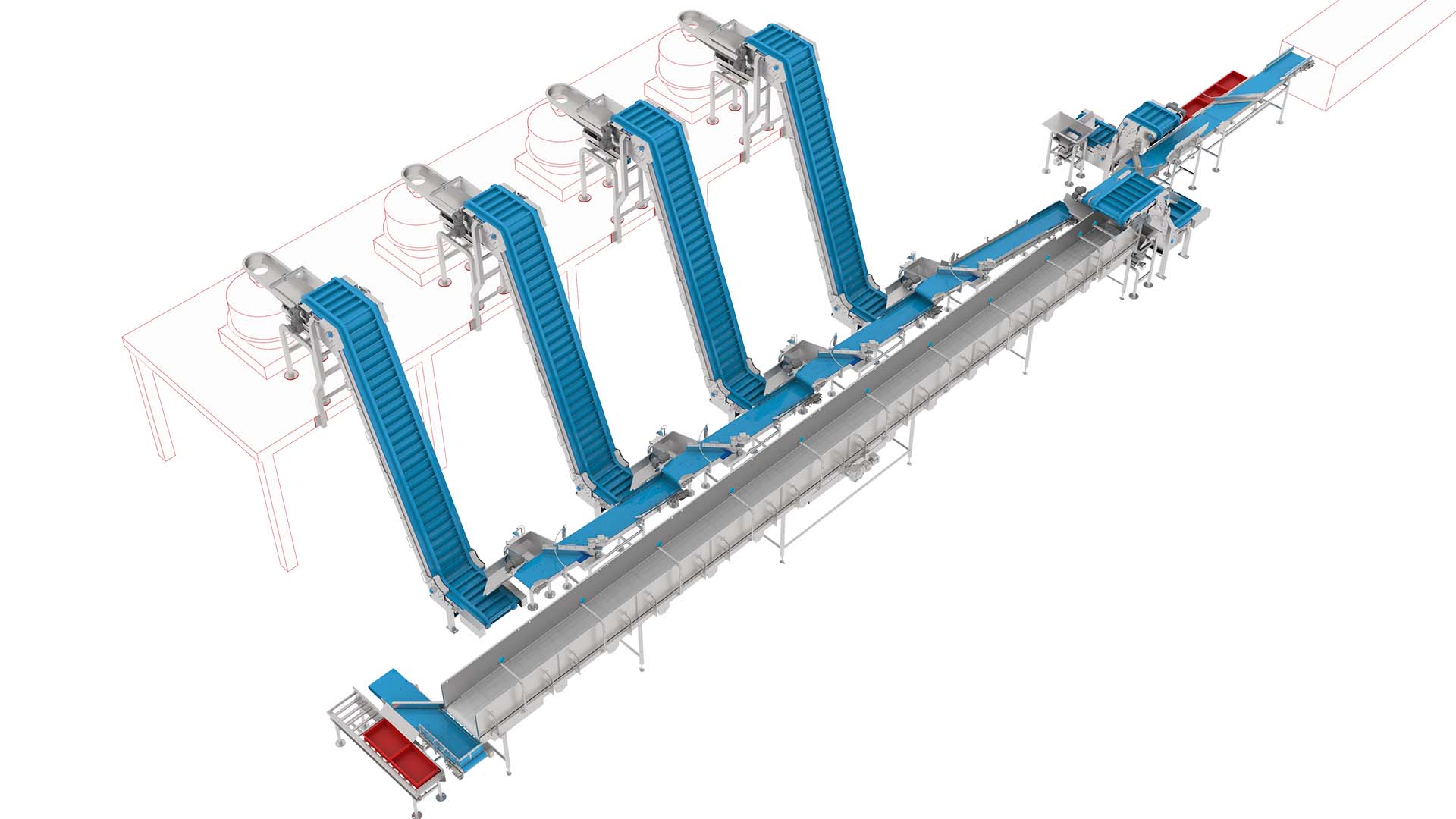

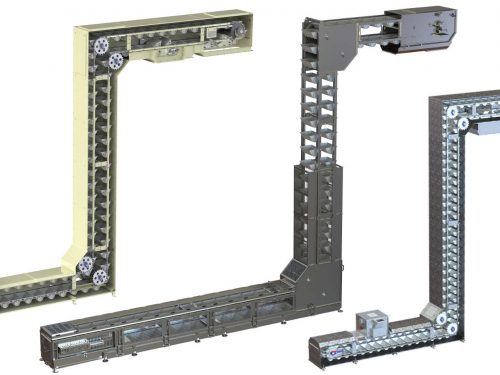

Full 'swan neck'

design with infeed

and outfeed sections.

Incline and outfeed

section

Can be designed

to suit your

specific requirements

Proven Technology

Podmores Flighted Belt Elevators are found in factories all over the world, from small businesses to household name companies. Podmores Belt Elevators help to move almost every product imaginable and are trusted in critical production line processes. Their durable design means almost no downtime.

Optimised

Our hygienic range can feature a cantilever design to allow for belt removal in minutes, to assist with full cleaning and maintenance. We can include full washdown features and regularly put our elevators into tough and demanding applications, such as met and seafood environments with rigorous cleaning protocols.

Gentle but tough

Podmores Flighted Belt Elevators offer an incredibly gentle solution in a robust design that’s built to last. Since 1930 we’ve handled almost every product imaginable, including products as gentle as chocolate curls/shavings and without damaging hard candy shells, and as tough as abrasive aggregates and metal swarf. This experience and our testing/demonstration facilities allow us to prove to you that our solutions are the best option for our orientation and sorting needs.

Fill and forget

Our expertise with Storage & Infeed Systems allows us to deliver a solution no matter how much product you want to hold and how little you want to have to top the system up. Podmores can help you deploy storage solutions that keep your operatives free for other tasks around your factory.

Want to find out more?

Controllers

Side guides

Hygienic Design

ATEX

Related products

Get in touch

Contact Us

ADDRESS

Podmores (Engineers) Ltd

Unit H Great Fenton Business Park, Grove Road, Stoke, Staffordshire,

ST4 4LZ, UK

Solving automation problems since 1930