Feed products at ultra high speed with Podmores’ ServoPOD. Servo based technology for parts singulation and orientation, delivering up to 300ppm.

| Voltage | 230V |

|---|---|

| Frequency | 50Hz |

| Materials | FDA Approved Plastics, SS304 |

| IP Rating | IP54 |

Share

Learn more

Videos

Vibratory Linear Feeders

High speed feeding

Up to 300ppm!

Even Feeding

Delivers product evenly and consistently when you want it.

Variable Speed

Adjustable outfeed rate (up to 300ppm) selected by you on the touchscreen HMI.

Infeed Solutions

Podmores offer a wide range of bulk storage infeed solutions to reduce operator refill times.

Quality Control

Optional vision add-ons allow pack orientation detection for logo detection or poka-yoke confirmation.

Low Noise Level

The emission sound pressure level of our ServoPODs is below 75 dB(A) at 1m distance, without product (Lpa re. 20µPa).

Low Running Cost

Costs as little as £2.90/hr to operate.

Small footprint

Standard unit is only 3.4m x 1.3m.

Quick lead times

Ready to ship in up to 20 weeks.

Want to find out more?

Applications

- Almost any component/product

- Cereal bars

- Chocolate bars

- Chocolate packs

- Cheese portions

- Chewing gum

- Coffee bags

- Coffee sticks

- Confectionary

- Food to go

- Meat snacks

- Petfood

- Protein snacks

- Snack Foods

- Tea

- Tea bags

- And more

Key benefits

High speed parts feeders form a critical process in many production lines. The ability to accurately deliver large quantities of product is vital to meet modern industrial automation requirements.

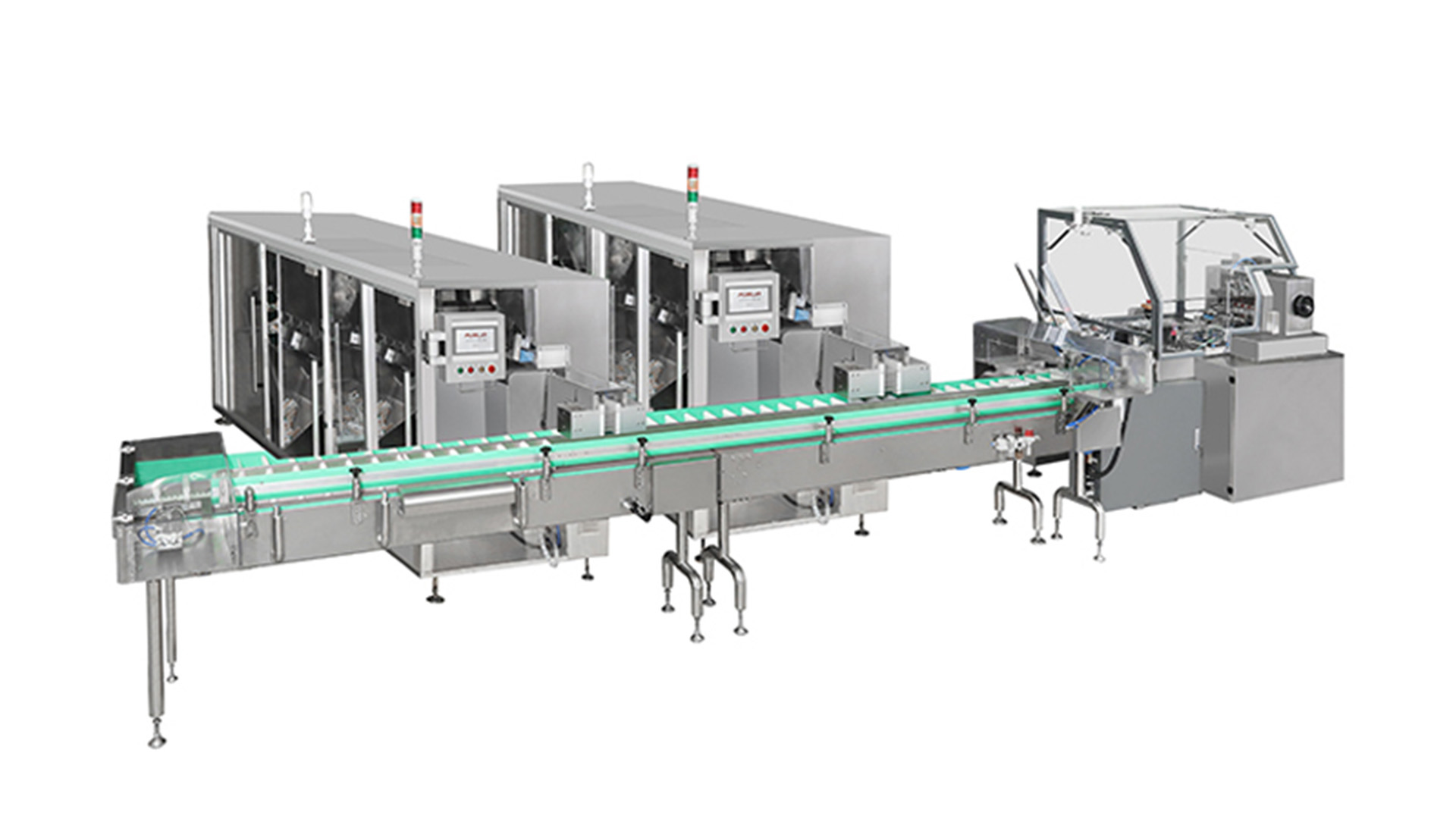

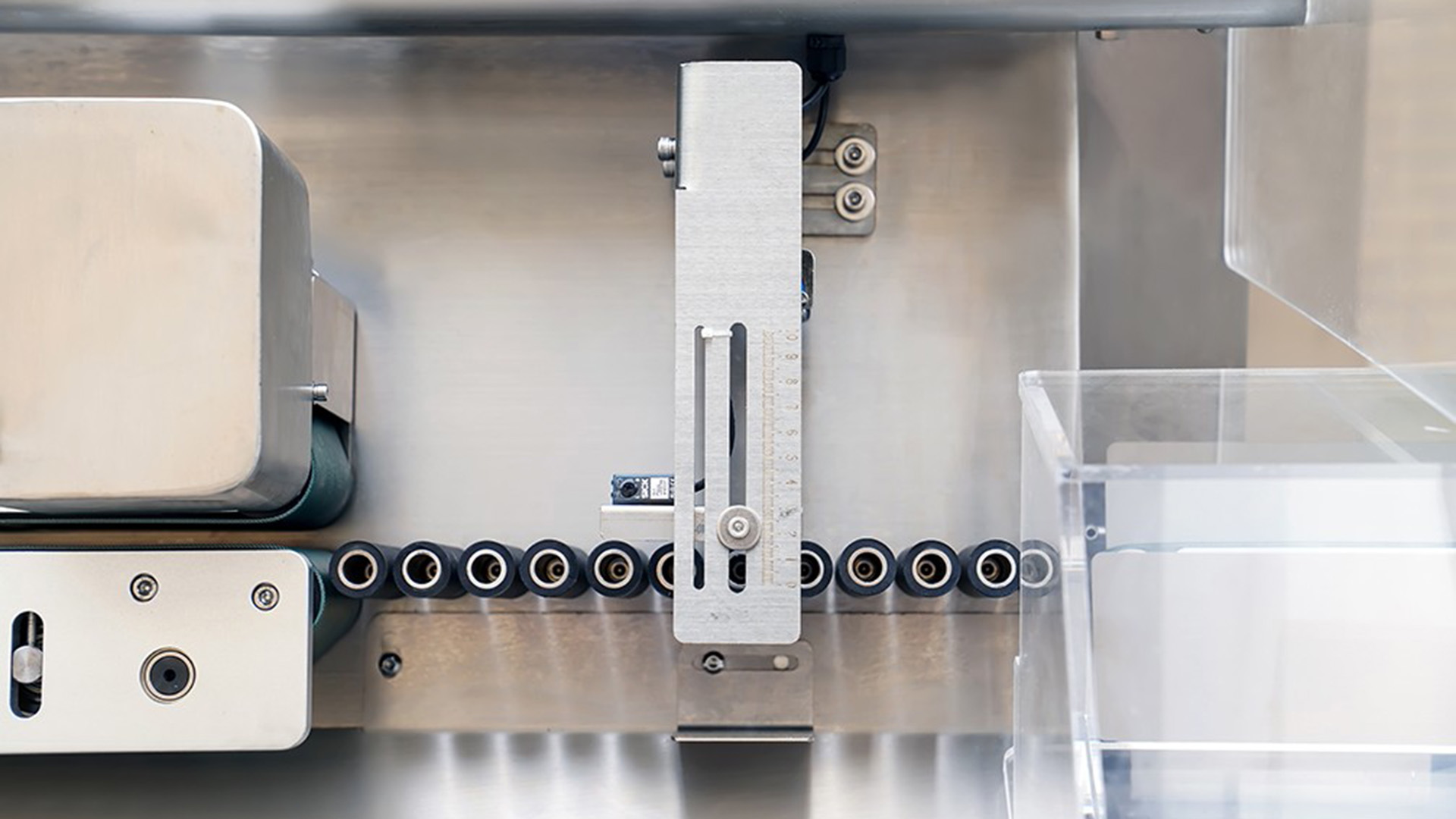

Product is loaded into the ServoPOD either manually or automatically into the bulk hopper. The product is then conveyed up and onto a series of individually controlled conveyor stages or zones where sensors are used to detect product and pull/push it until the product is singulated and the correct orientation. The ordered stream of product leaving the machine goes through a double check where its height and orientation are confirmed.

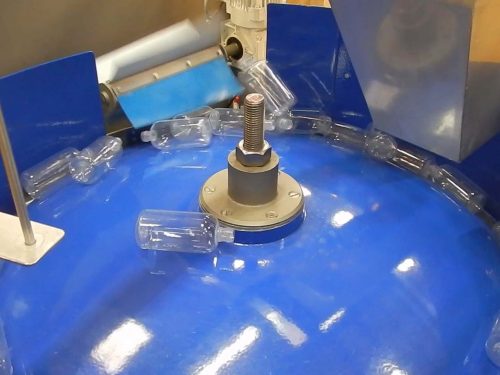

Optionally, a vision system can be used to look for the front/bottom of the pack and confirm its orientation. This is useful when feeding robot picker belts as the ServoPod can ensure only ‘logo up’ product is allowed to continue onto the robot picker belt and wrong way up product is instantly returned to the ServoPOD’s storage hopper.

- Servo driven for faster throughputs.

- Up to 300ppm.

- Instant start/stop

- Constant feed rate that doesn't adjust over time.

- Interchangeable rollers for product selection.

- Siemens based control pack.

- Vary speeds easily and simply using the touchscreen HMI.

- Quiet operation.

- Available in under 20 weeks typically.

- Quick return on investment (ROI).

- Optional vision inspection for logo detection/pack presentation configurations.

Loading & storage

elevator

Multi zone servo

singulation

Adjustable

pouch/sachet

conditioner

Adjustable

outfeed

Touchscreen

HMI

What's going on?

Hover over the dots to the left to find out more about the ServoPOD.

Designed for a wide range of products

Designed to be flexible for a wide range of primary packed products. Capable of handling products up to 200mm in length.

Accurate

In addition to interchangeable rollers which only allow products the correct orientation/size to remain on the conveyors, the ServoPOD features a width and height check point with reject back in to the buffer storage conveyor. this is easily adjustable for different products.

Counting & batching

An individual ServoPOD can be used to count product at high speed for counting applications, and can be combined with multiple units in synchronisation to create custom pack formats with multi-flavour/multi-pack combinations.

Easy to integrate

- 230V 50Hz 16A (3.68kW power supply).

- 4 full swivel castors to help you move it into position.

- Rigid sub-frame allows forklifting onto mezzanines with 2T forklift truck.

Want to find out more?

Controllers

Metal finishes

Electromagnetic Coils

Hygienic Design

ATEX

Get in touch

Contact Us

ADDRESS

Podmores (Engineers) Ltd

Unit H Great Fenton Business Park, Grove Road, Stoke, Staffordshire,

ST4 4LZ, UK

Solving automation problems since 1930