Multihead Weigher Infeeds

Podmores offer a comprehensive range of Multihead Weigher Infeed

solutions no matter what configuration you require

Want to find out more?

Welcome to Podmores

From a single hopper infeed to a complicated multi product distribution system, we have solutions to help you keep your weighing & counting applications running at full speed.

We have experience of keeping Multihead Weighers supplied with product ranging from a basic hopper unloader feeder through to full multiple Multiheads running a mix (blend) configuration.

Multihead Weighers are heavily dependant on the quality of the infeed to them. If you can ensure that product is always available and fed into the Multihead when required then you will significantly increase the Multihead’s efficiency.

Podmores have have over 90 years of experience in materials handling and can ensure that your Multihead is fed appropriately to allow it to produce batches at the rate you need with the quality and accuracy that you require.

Watch The Video

Why Podmores?

90 years of experience

Podmores infeed systems can help you achieve 99% efficiency on your pack weighments. Using instant start/stop Vibratory Linear Feeders to top up your Multihead you can realise immediate savings by keeping the multihead topped up in the most efficient way. Compared to a Podmores Vibratory infeed solution, our vibratory product range offers significant cost savings. Below are key weighment accuracy (based on target weight) for a 20 head industry leading Multihead and show how important your infeed decision can be.

Turnkey solutions

From a single feeder to full production lines with mezzanines.

Instant start/stop

Our vibratory feeders start & stop immediately for a responsive infeed.

Maximise efficiency

Reduce giveaway or under target batches by accurately feeding in.

Optional processes

Screen out over/under size product, remove dust, ensure quality.

Any multihead

We can integrate with any manufacturer's multihead products.

System controls

Full system controls available with inhouse PLC & HMI programming support.

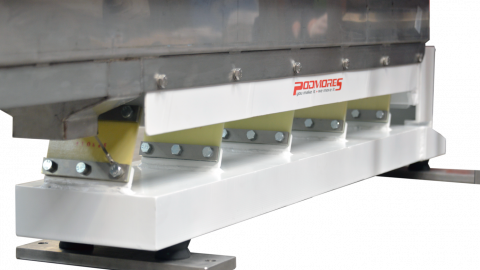

Custom feeder ends

Options to suit distribution cones or segments of multiheads.

Single supplier

We can offer a complete solution and a single supplier to order from.

Radial circular discharge end

for maximum efficiency, a wide range of ends are available.

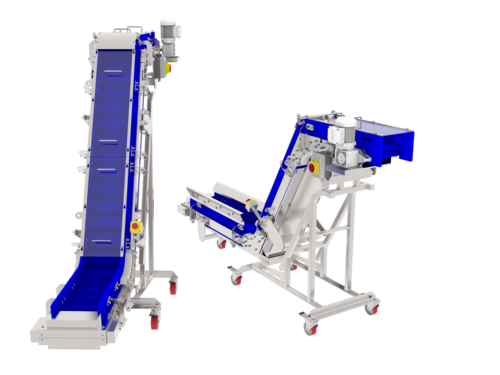

Hygienic design flighted

belt elevators. Bucket

Elevators and Bin

Tippers are available

Buffer Hoppers

Belt diverter ploughs,

pneumatically actuated.

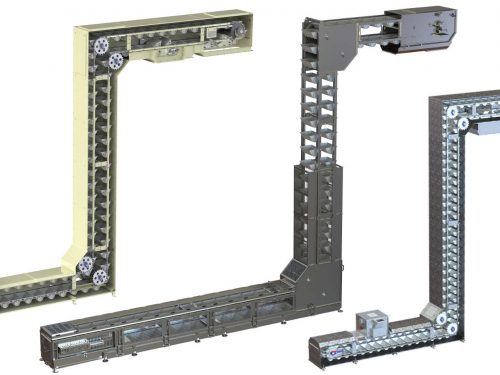

Storeveyor for bulk

medium or long term

buffer storage

Traying off bench

to empty the system

Vibratory Crosshead

Linear Feeders

Infeed with divert to

manual traying off,

divert to Storeveyor

or run on to main line.

Hover over the arrows above to learn more

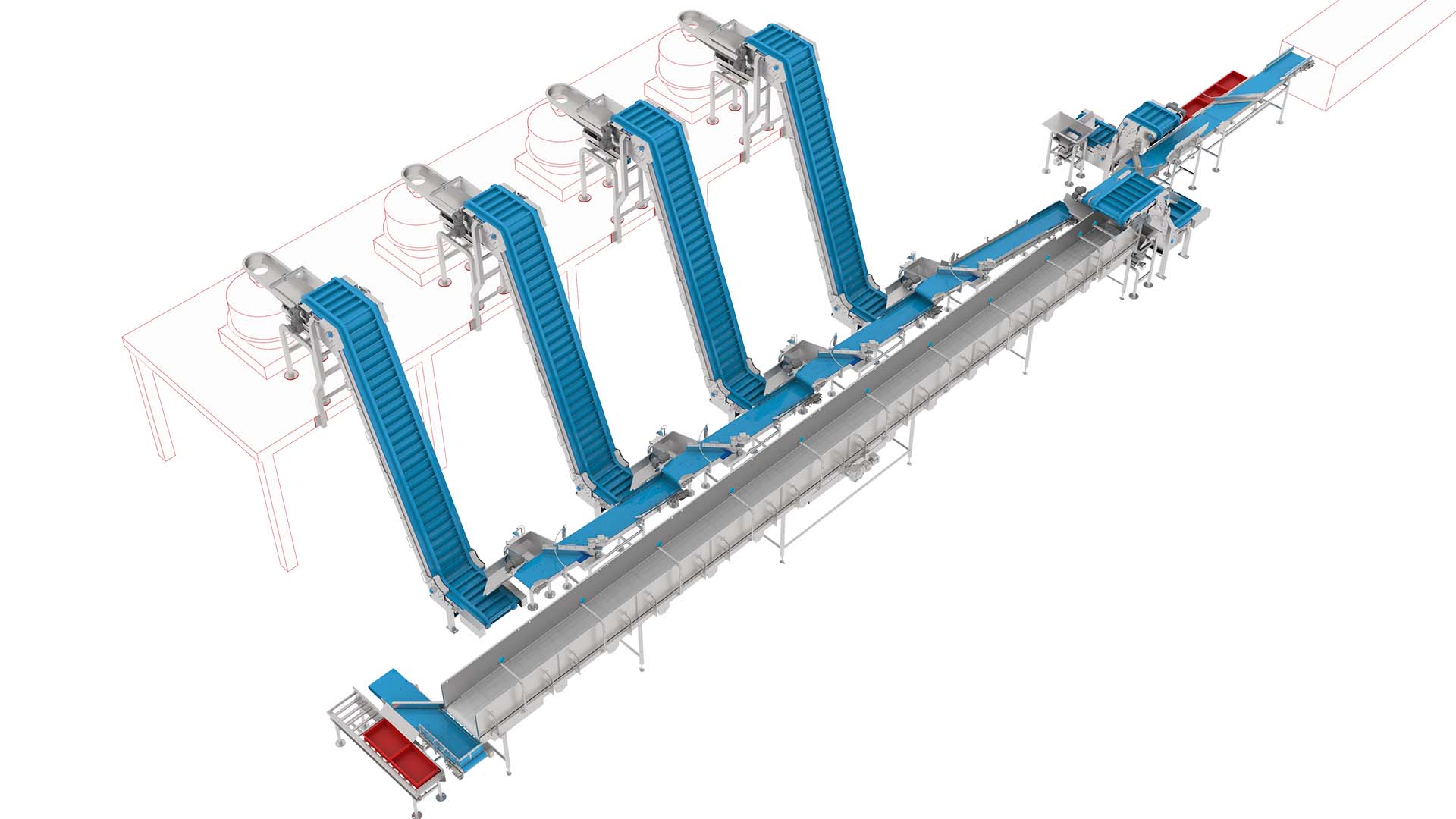

Single product,

many multihead weighers distribution systems

Product enters from the conveyor at the top right. It can be sent either left into a bulk Storeveyor or right onto the main line.

Product travelling down the main line can be diverted off into Buffer Hoppers that feed Flighted Belt Elevators (Swan Neck type) that in turn feed vibratory Crosshead Feeders.

Product in the Storeveyor can either be reversed back onto the main line (Last in, first out, LIFO), or fed forwards to a traying off bench, or other storage solution.

Load product on the ground floor either by hand, or using lifting equipment (forklift truck, etc). Our system will alert you when it needs topping up and then manage the balanced feed straight into the Multihead.

The photo above shows a typical ground floor Hopper Feeder, Flighted Belt Elevator and Crosshead Vibratory Linear Feeder to feed a balanced stream of product onto the Multihead distribution cone.

The photo to the right/below shows a large capacity ground floor Hopper Feeder (1.5m3) feeding a quality control Vibratory Screen Feeder that is removing large/oversize product that in turn feeds a Flighted Belt Elevator.

The most popular choice

Single product,

single multihead weigher Infeed Systems

Simplest solution

Single product,

single multihead weigher Infeed Crosshead Feeders

For directly feeding Multihead Weighers, Podmores’ Crosshead Feeders can accept product tipped in by hand (manually loaded) or from a FIBC ‘big bag’ outlet spout.

Our vibratory Crosshead Feeders incorporate design functionality to ensure no matter how much product is in the hopper, the Vibratory Feeder can operate up to its maximum throughput.

Optionally, screening of the product can be incorporated to remove over or under sized product before it reaches the Multihead, ensuring quality and consistency of bagged product. The removal of dust or fine particles is particularly important where bagging or tray sealing takes place later down the production line because the small particles can interfere with the sealing process, rendering product as scrap.

Materials Handling & Factory Automation experts

We have experience in handling almost every product and can help you achieve your next automation project with our expertise and knowledge.

Want to find out more?

Podmores will work with you to scope out your application to deliver optimised product delivery to your Multihead Weigher(s).