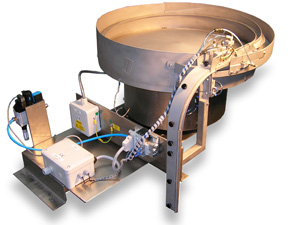

Podmores have developed an infeed system to prepare short emery boards for individual packaging. The system lines up two emery boards side by side and when the bagging machine is ready for them it discharges both emery boards into the vertical form, fill and seal machine.

Podmores have developed an infeed system to prepare short emery boards for individual packaging. The system lines up two emery boards side by side and when the bagging machine is ready for them it discharges both emery boards into the vertical form, fill and seal machine.

The bowl feeder is a 304 stainless steel fabricated unit suitable for pharmaceutical and related use and will orientate two emery boards at a rate of 60 per minute. The stainless steel discharge chute was specifically designed to act as a storage system when the bagging machine was not ready to receive the product, but without reducing the feed rate of the bowl feeder. Because the bowl feeder was to be filled by hand it is a perfect design due to having no dangerous moving parts. It’s wide diamater acted as a hopper for the emery boards placed in it.

This bespoke system was specially designed for this application but similar systems can also be developed to handle products for the following industries: aerospace, automotive, chemicals, cosmetics, electronics, food & beverage, medical & biotech, military, mining, packaging, pharmaceutical, plastics & recycling.

This bespoke system was specially designed for this application but similar systems can also be developed to handle products for the following industries: aerospace, automotive, chemicals, cosmetics, electronics, food & beverage, medical & biotech, military, mining, packaging, pharmaceutical, plastics & recycling.

For more information, please contact us.