Knowing how your Vibratory Linear Feeder or Vibratory Bowl Feeder is performing is a critical part of any maintenance and performance monitoring process. Podmores have made available various tools to help you measure the amount of deflection (sometimes also known as the amount of amplitude or amount of vibration). Read on to find out which tool is best for your machine and how to use it.

Vibratory machines with electromagnetic coils

Examples of high frequency electromagnetic coil machines.

If your machine has an electromagnetic coil or vibrates at a high frequency (typically 30-100Hz) then use the download below to measure its deflection.

- Print at 100% (no scaling)

- Measure if your spring stations are at 70° or 65°

- Cut around the correct box for your spring angle

- Laminating the gauge can extend its life

- Use double sided tape/glue to afix to machine

- Ensure the gauge runs parallel with the machine

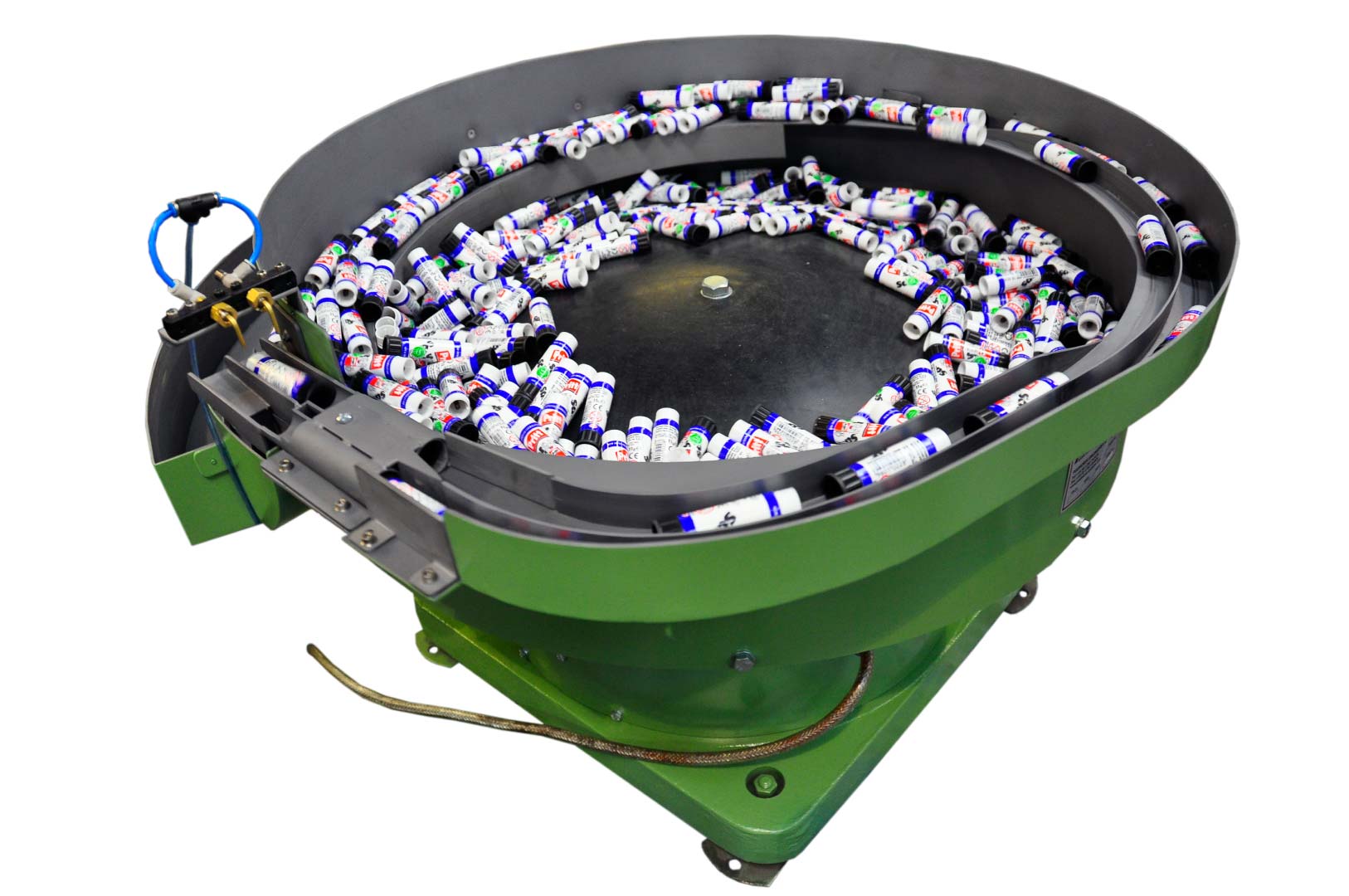

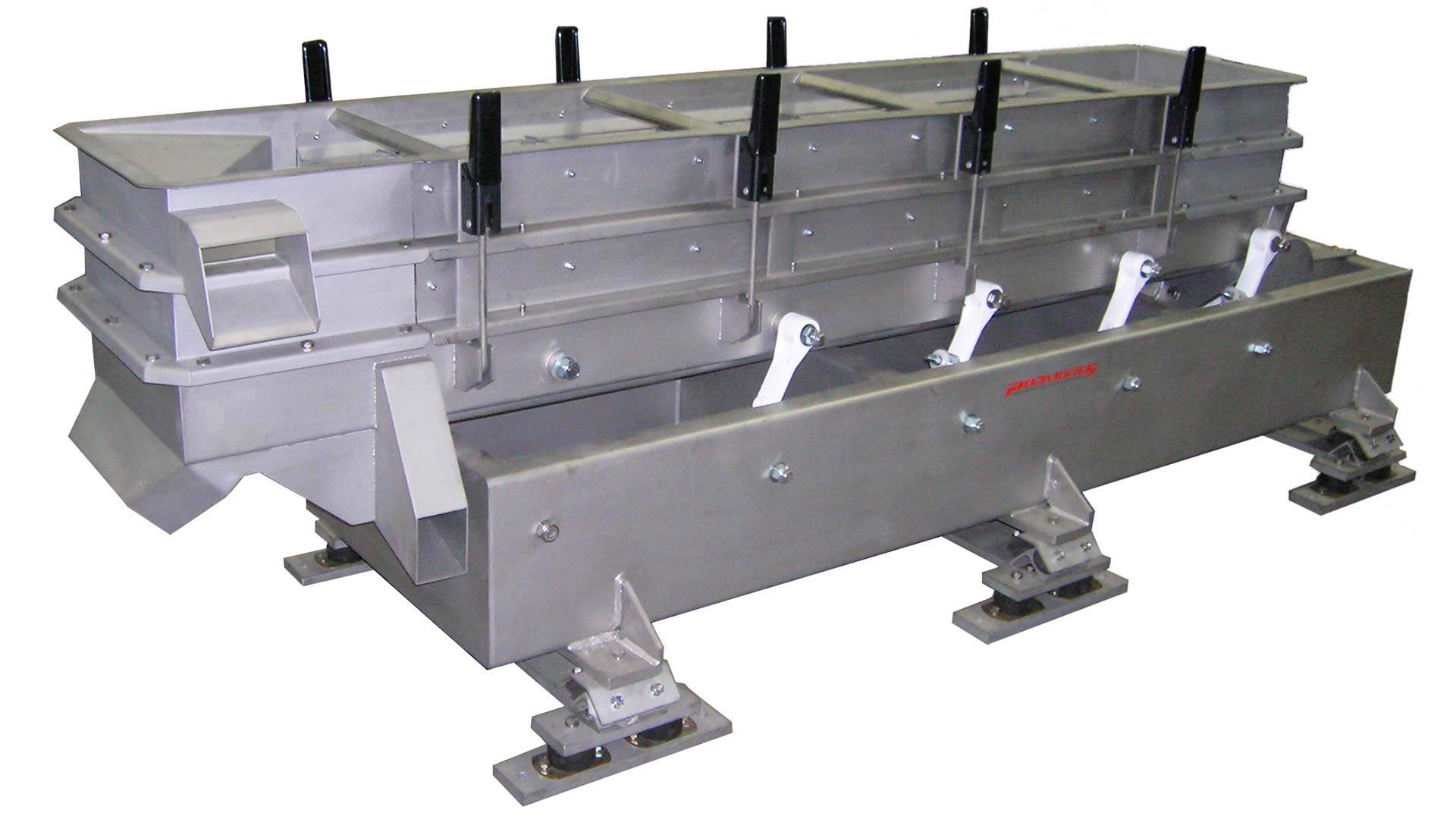

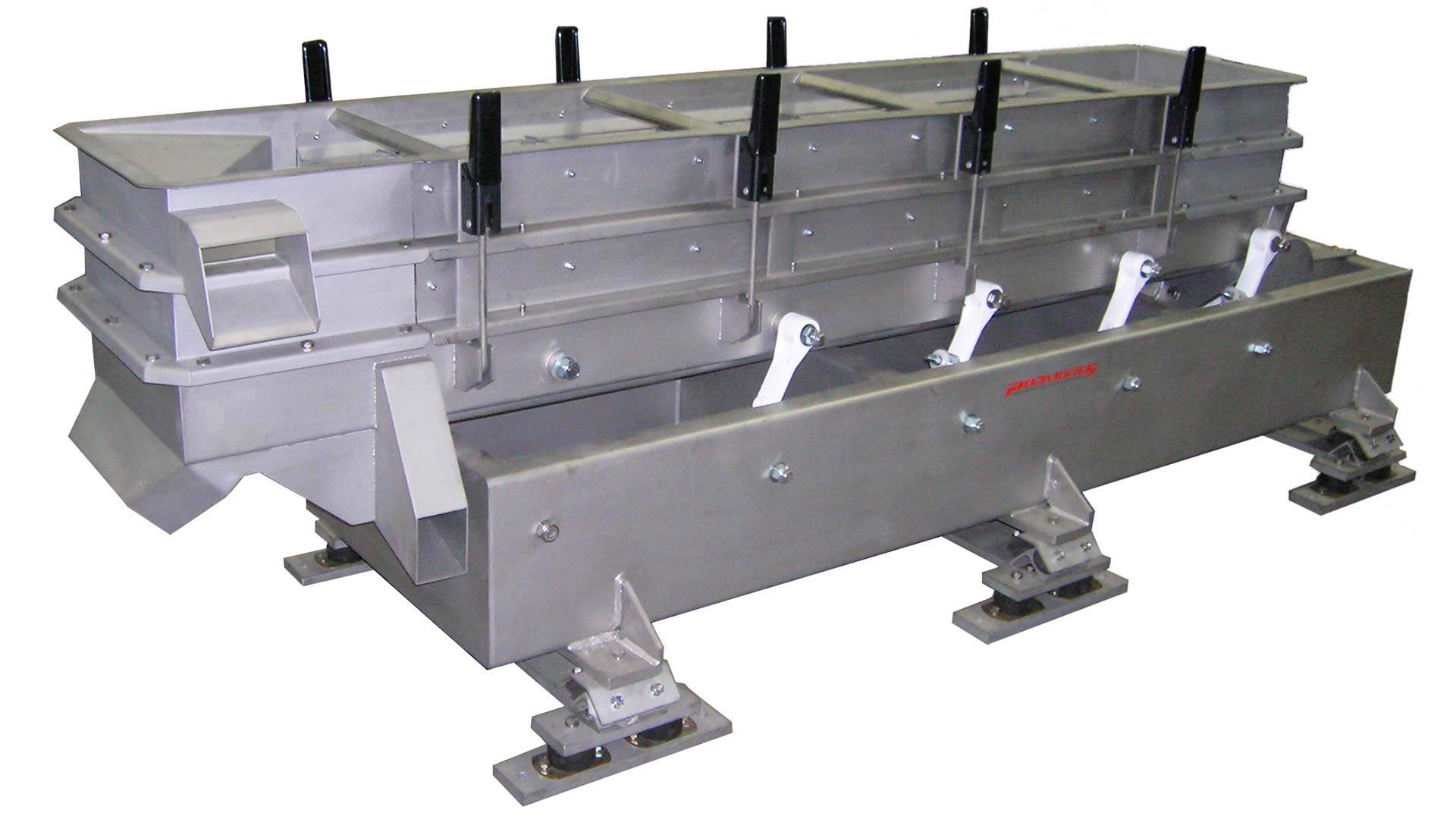

Vibratory machines with motors

Examples of low frequency motor machines.

If your machine has an electromagnetic coil or vibrates at a high frequency (typically 30-100Hz) then use the download below to measure its deflection.

- Print at 100% (no scaling)

- Cut around the box

- Laminating the gauge can extend its life

- Use double sided tape/glue to afix to machine

- Ensure the gauge runs parallel with the machine

How to use a deflection gauge

We’ve made two methods available for measuring the deflection, the “V-Gauge” and “Circle” method. Both methods should give the same result and so the choice of which method to use is up to personal preference.

V-Gauge Method

When the machine is switched off the two lines on the gauge converge at zero.

When the machine is vibrating its deflection will be determined by the new convergence point of the lines.

The graduations on the gauge in millimetres e.g. a reading of 6 indicates a deflection of 6mm.

NOTE: Some deflection gauges use imperial measurements in ten thousandths of an inch, use this reference table below to convert:

Imperial Gauge value | Imperial (in) | Metric (mm) |

|---|---|---|

1 | 0.010 | 0.25 |

2 | 0.020 | 0.50 |

3 | 0.030 | 0.75 |

4 | 0.040 | 1.00 |

5 | 0.050 | 1.25 |

6 | 0.060 | 1.50 |

7 | 0.070 | 1.75 |

8 | 0.080 | 2.00 |

9 | 0.090 | 2.25 |

10 | 0.100 | 2.50 |

Circles Method

Where the circles appear to touch this indicates the machine is vibrating at the indicated level. The graduations on the gauge in millimetres e.g. a reading of 1.75 indicates a deflection of 1.75mm.